- 1. Speed can reach 7rows/minute

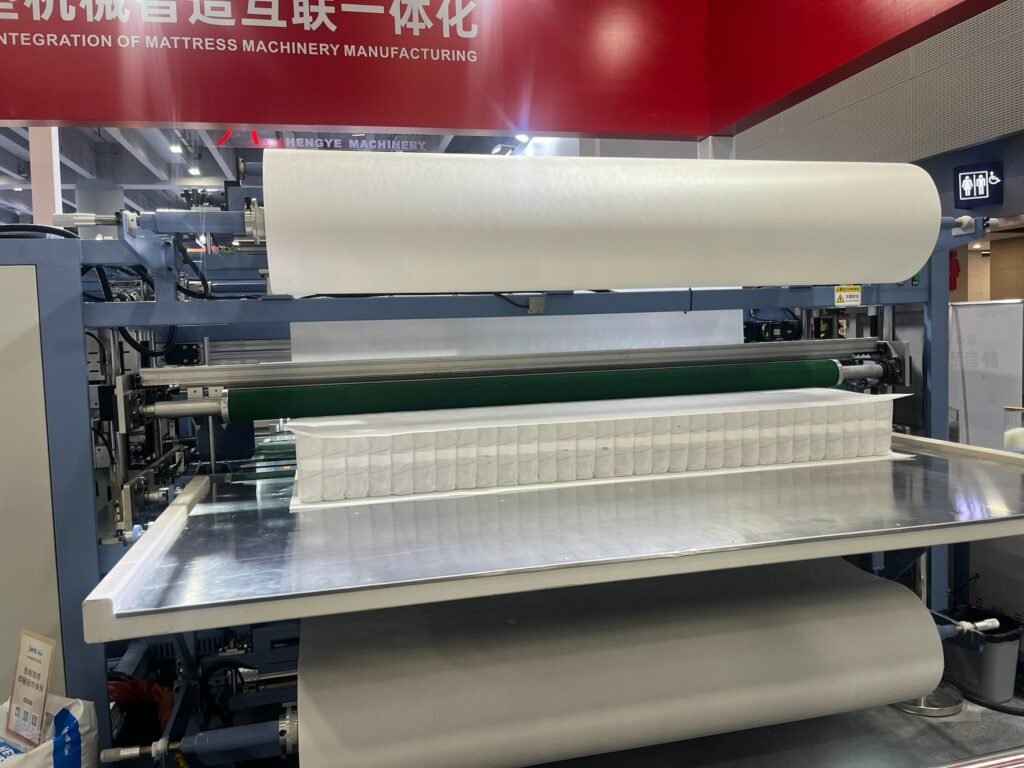

- 2. None, single-sided or double sided gluing is available

- 3. Parrallel or nest gluing is available

- 4. Continuous or intermittent gluing is optional

- 5. Easy to operate and maintain; 6. Special protective device.

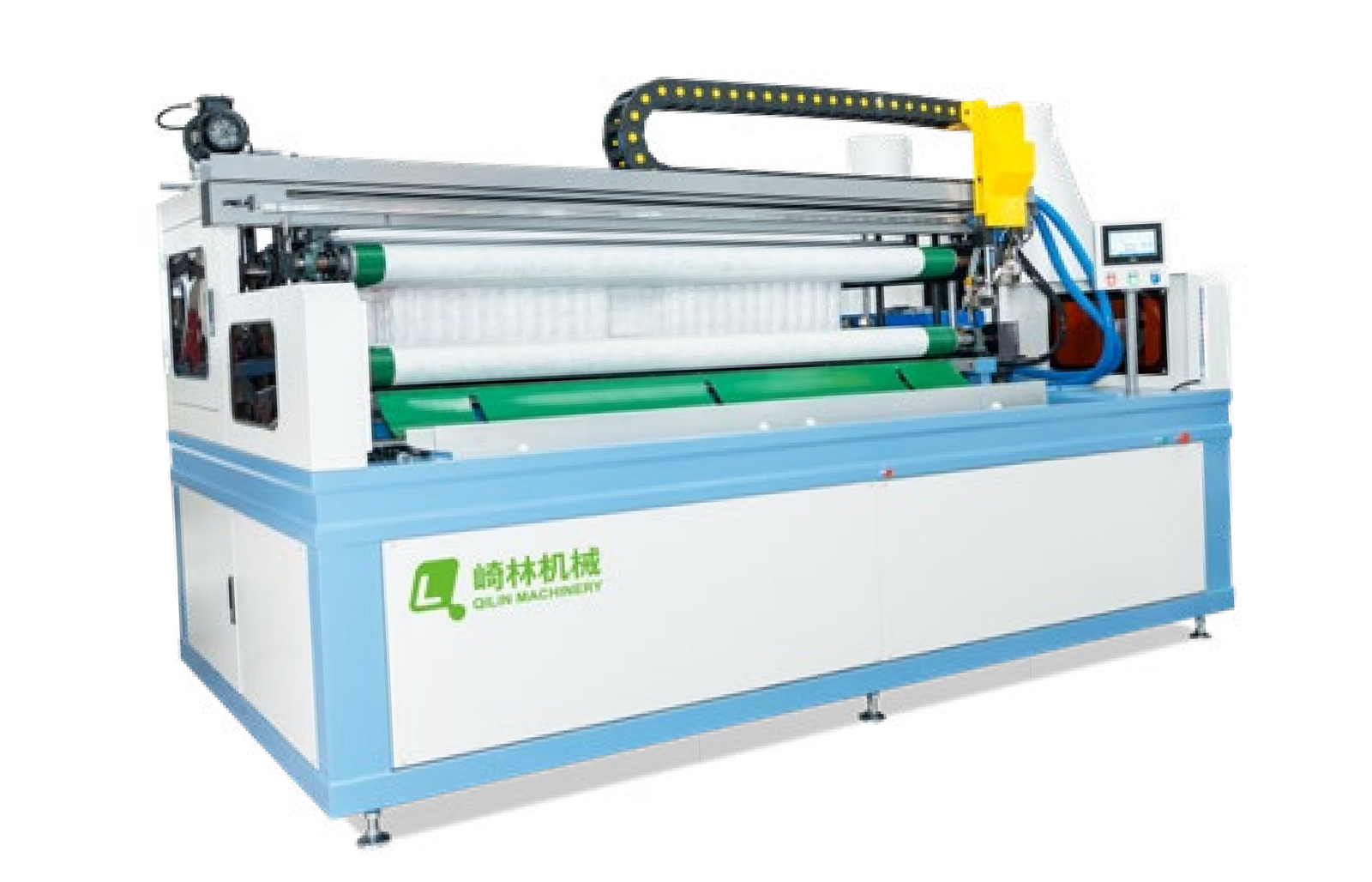

Detail For Mattress Spring Assembling Machine

- main production of pocket spring mattresses or pocket spring sofas, and can bond bagged spring strips. Product description: Pocket spring assembly machine is a popular spring bed net bonding equipment in the industry. This machine is mainly used for the

- groove, which can accurately and quickly feed. It is a specialized equipment for producing pocket spring mattresses or pocket spring sofas. The ZJ1R Semi-automatic pocket spring assembly machine not only has the advantages of easy operation and stable production, but als

Application Of Mattress Spring Assembling Machine

| Item | ཁྱད་ཆོས། |

|---|---|

| Model | ZJ1R |

| Efficiency | སྐར་མ་རེར་ཕྲེང་7ཙམ། |

| Air requirement | 0.3 m³/min, 0.6 MPa |

| Power requirement | 3P 380 V 50 Hz (can be customized) |

| Working temperature | 0–35 °C |

| Total power | 12 kW |

| Gross weight | About 2350 kg |

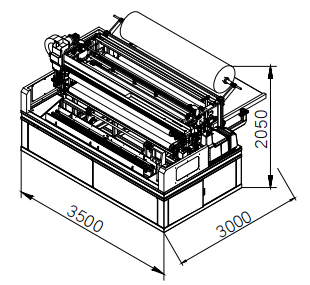

| Machine size (about) | 3500 × 3000 × 2050 mm |

| Operation | Feed the pocket spring strings manually |

| Control of assembling platform | Electronic control |

| Gluing method | Continuous or intermittent gluing |

| རྒྱུ་ཆའི་ཁྱད་ཆོས། | |

| Pocket spring height | 60–280 mm |

| Spring central diameter | φ45–80 mm |

| Non‑woven thickness | 70–100 g/m² |

| Non‑woven width | 450–2200 mm |

| Inner diameter of non‑woven | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. |