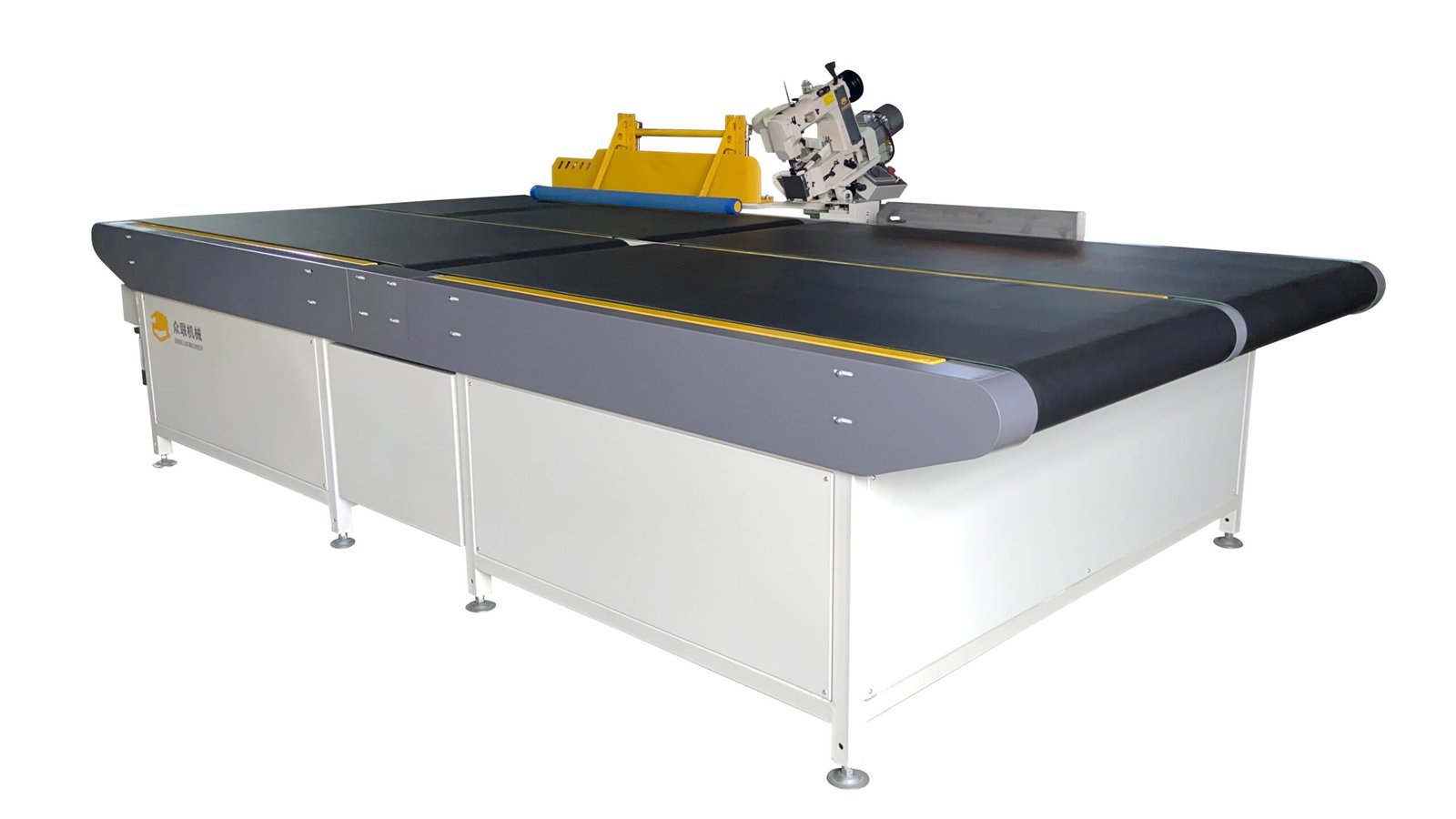

Automatiske madrassyningsmaskiner til effektiv produktion?

Struggling with high labor costs, inconsistent stitching, or slow turnaround in mattress manufacturing?

Automatic mattress sewing machines solve these problems by streamlining the stitching process with consistent speed, quality, and automation.

If you’re trying to scale up your mattress production, reduce operator errors, and stay competitive in today’s fast-paced market—this guide is for you.

What makes automatic sewing machines ideal for mattress production?

Manual processes slow down production and increase inconsistency in mattress stitching.

Automatic mattress sewing machines improve speed, stitch consistency, and reduce manual labor in large-scale manufacturing.

Dive deeper: Understanding their core benefits

💡 Automation reduces human error

Machines operate with programmable logic. They don’t get tired or distracted. That alone increases productivity and reduces the error rate dramatically.

⚙️ Consistency is key

Uniform stitches aren’t just a visual thing—they affect the structural durability of your product. Automatic systems eliminate skipped stitches, tension issues, and misaligned seams.

🔁 Designed for scale

Whether you’re producing 200 or 2000 mattresses per day, automatic machines keep up. Many models come with programmable patterns for different mattress styles and can adapt quickly to new orders.

| Funktion | cURL Too many subrequests. | Automatic Sewing |

|---|---|---|

| Stitch Accuracy | Operator dependent | Programmable precision |

| Operator Fatigue | Høj | Minimal |

| Output per shift | 80–150 units | 250–600+ units |

| Pattern Flexibility | cURL Too many subrequests. | High (with saved templates) |

| Arbejdskrav | 2–3 operators per station | 1 operator for oversight |

Our factory used to run 5 manual stations. Switching to 2 automatic units tripled our output with half the staff. That’s not theory—it’s my personal experience.

What key features should I look for?

Not all machines are built equal. Features determine if the machine fits your production flow or slows it down.

You need to consider stitch control, programming interface, changeover time, and durability before investing.

Dive deeper: Machine features that matter

🧵 Stitch type and pattern library

Look for machines that can do chain stitch and lock stitch. Also, make sure the software supports various quilting or edge-pattern styles.

💻 Interface and software

A touchscreen interface with memory for pattern presets helps operators set up in minutes. Avoid machines that require manual dials or outdated firmware.

⚙️ Speed control

High-speed is important, but adjustability is more important. Look for servo motor control that allows you to dial in the perfect rate for different materials.

🛠️ Maintenance access

Choose machines with tool-free access panels for threading and cleaning. Machines with self-lubrication and auto tension adjustment cut downtime.

| Specifikation | cURL Too many subrequests. | Ideal Specification |

|---|---|---|

| Systid | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

| Function | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | Stop-and-check | Auto alert + resume system |

After integrating sewing with our CNC cutter and foam stacker, our production line went from 2.5 hours to 55 minutes per mattress.

What does it cost and is it worth it?

Some owners hesitate because of the upfront investment—but that short-term cost often unlocks long-term profitability.

Automatic machines cost more, but their ROI comes from reduced labor, fewer errors, and much faster turnaround.

Dive deeper: ROI and investment breakdown

💰 Typical cost range

- Entry-level semi-auto: $8,000 – $12,000

- Mid-range programmable: $15,000 – $25,000

- High-end full automation: $30,000 – $45,000

🧮 ROI calculation (example)

If one operator on a manual line outputs 100 units/day:

- Labor cost = $80/day

- Mistake rate = 3%

- Daily cost of errors and labor = $80 + $60 waste = $140

With an automatic machine:

- Output = 300 units/day

- Labor cost = $40/day (oversight only)

- Mistake rate = 0.5%

- Daily cost = $40 + $10 = $50

Payback period = Machine cost ÷ Daily savings

= $20,000 ÷ ($140–$50) = ~223 days

That’s less than 8 months.

| Cost Factor | Manual Sewing Line | Automatic Sewing Machine |

|---|---|---|

| Upfront Cost | $3,000 – $5,000 | $15,000 – $40,000 |

| Daglig produktion | 80–150 units | 250–600 units |

| Operatører nødvendige | 2–3 | 1 |

| Training Time | 2–4 weeks | 2–3 days |

| Yearly Maintenance | Høj | Low (preventive only) |

We recovered our investment in under 6 months and haven’t looked back.

Konklusion

Automatic mattress sewing machines are not just faster—they’re smarter, more consistent, and far more scalable. For anyone serious about growth in mattress manufacturing, they’re the future.

https://mattressmachineryzl.com/wp-content/uploads/2025/02/mattress-spring-machine5-scaled.jpg