Können Matratzenfedermaschinen für spezielle Bedürfnisse angepasst werden?

Können Matratzenfedermaschinen für spezielle Bedürfnisse angepasst werden?

Mattress factories are facing a growing demand for personalized comfort and diversified product lines. But can the machines behind spring production evolve accordingly?

Yes, mattress spring machines can be customized to meet specific production needs—including spring type, tension, layout, and automation level. This flexibility allows manufacturers to adapt to market shifts, customer preferences, and product innovation.

Customization helps us deliver targeted support, varied firmness levels, and differentiated mattress structures across different markets.

What Are Mattress Spring Machines and How Do They Work?

Manufacturers today are no longer producing just one type of spring. We need machines that support multiple configurations.

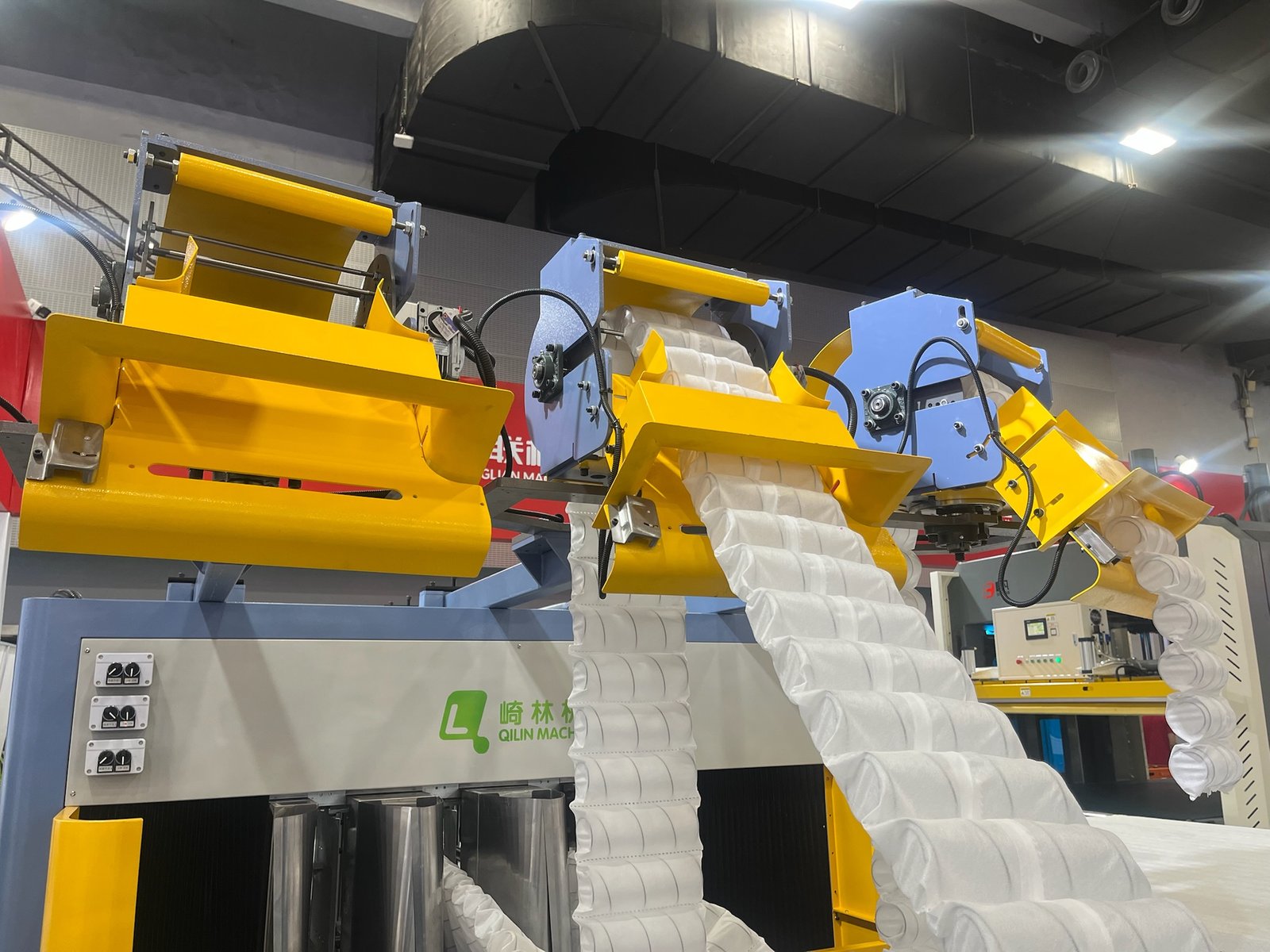

Mattress spring machines are specialized equipment used to produce the inner spring units of mattresses. These machines automate the coiling, cutting, assembly, and sometimes the fabric wrapping of individual or interconnected springs.

Types of Mattress Spring Machines:

| Maschinentyp | Spring Output | cURL Too many subrequests. |

|---|---|---|

| Bonnell Spring Machine | Hourglass-shaped coils, connected | Traditional and low-cost innerspring beds |

| Pocket-Feder-Maschine | Individually encased coils | Premium, orthopedic, hybrid mattresses |

| Continuous Coil Line | Single wire with linked coils | High-durability, mid-range mattresses |

| Offset Coil Machine | Hinged, body-contouring springs | Ergonomic and zoned support mattresses |

Each machine type supports unique mechanical principles—and each can be tailored for different customer or product requirements.

What Customization Options Are Available?

Customization goes far beyond adjusting spring height. With modern engineering and software, we can fine-tune nearly every variable in spring design and layout.

Key Customization Variables:

- Spring Diameter: Affects firmness and airflow

- Wire Gauge: Heavier gauge means firmer feel

- Federhöhe: Determines mattress profile and bounce

- Zoning: Varying coil tension across head, shoulders, and hips

- Coil Shape: Hourglass, cylindrical, or conical designs

- Coil Layout: From single-row patterns to multi-zoned layering

- Wrap Fabric Type: For pocket springs (polypropylene, felt, etc.)

By customizing these settings, manufacturers can produce mattresses for distinct markets—orthopedic support in medical facilities, plush zones for luxury brands, or reinforced edges for hotel use.

How Does Technology Support Customization?

Today’s spring machines are no longer static. They’re dynamic systems designed to evolve.

cURL Too many subrequests.

-

cURL Too many subrequests.

cURL Too many subrequests. -

cURL Too many subrequests.

cURL Too many subrequests. -

cURL Too many subrequests.

cURL Too many subrequests. -

cURL Too many subrequests.

cURL Too many subrequests. -

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- HospitalitycURL Too many subrequests.

- HealthcarecURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Benefits:

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Skilled Operation: Operators must be trained to switch between multiple configurations.

- Maintenance Complexity: More adjustable parts mean more potential points of failure.

We addressed this by partnering closely with the machine supplier during the design phase and scheduling extended operator training after installation.

What Do Real-World Customizations Look Like?

Let’s look at examples from some of our customer partners:

-

A Southeast Asian mattress brand requested a three-zone pocket spring machine, with firmer coils in the lumbar zone. The machine was delivered with programmable tension feeders and triple-speed control.

-

A European OEM wanted a machine capable of switching between Bonnell and continuous spring types. Their custom line included interchangeable mandrels, two wire gauges, and software presets.

These real-world applications show that the concept isn’t theory—it’s scalable practice.

How Do We Collaborate With Customers?

To build truly customized machines, manufacturers and customers must work closely together.

Collaboration Process:

- Needs Assessment: Understand customer’s mattress types and comfort goals.

- Technical Design: Engineers propose machine modifications based on parameters.

- Simulation: CAD modeling and coil mapping tested before production.

- Factory Acceptance Testing: Customer signs off after real-world trials.

- On-Site Commissioning: Technicians provide full setup, training, and adjustment.

Our customers have appreciated being involved in the process—it builds long-term trust and leads to better machine outcomes.

Fazit

Mattress spring machines can be customized to meet specific manufacturing needs—from simple adjustments like wire tension to advanced, multi-zone layouts. By leveraging software, sensors, and modern design tools, we can help our customers produce exactly what their markets demand.

Customization allows us to adapt quickly, offer differentiated products, and serve specialized sectors like healthcare, hospitality, and luxury bedding. For manufacturers aiming to grow in competitive or diversified markets, investing in custom-capable spring machines is no longer a luxury—it’s a strategic necessity.