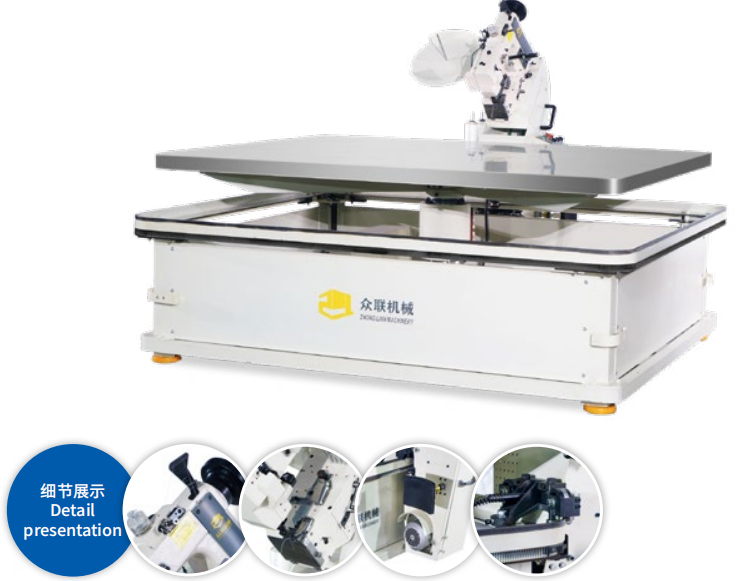

Principalmente utilizado para el encuadernado de bordes de colchones.

1. Frequency converter speed regulation with automatic corner deceleration ensures premium product quality;

2. Button-controlled worktable elevation and head tilt adjustment for operational convenience

3. User-friendly interface with stable operation, minimal vibration, and low noise;

4. Electronic clutch control for smooth start-stop transitions.

Table Of Contents For Mattress Tape Edge Sewing Machine

Application Of Mattress Tape Edge Sewing Machine

| Item | Especificación |

|---|---|

| Production efficiency | 10–15 hojas/hora |

| Sewing thickness | 30–450 mm |

| Head lifting range | 280 mm |

| Machine size (L×W×H) | 1720 × 2120 × 900 mm |

| Max speed | 2800 RPM |

| Total weight | 600 kg |

| Total power | 1.0 kW |

| Rated power supply | 380/220 V, 50/60 Hz |

¿Cómo elegir la máquina de cinta de borde para colchones adecuada?

Paso 1: Conoce tu escala de producción

| Tipo de fábrica | Producción diaria | Tipo de máquina recomendada |

|---|---|---|

| Pequeña fábrica | ≤20 camas/día | Semi-automático (serie 3A) |

| Fábrica mediana | 50–100 camas | Totalmente automático (serie 4B, cabeza de 5 agujas) |

| Gran planta | más de 200 camas | Totalmente automático (serie 5B, control CNC) |

Paso 2: Ajusta las especificaciones de tu colchón

| Característica del colchón | Parámetros clave de la máquina a ajustar |

|---|---|

| Extra grueso (>40cm) | Altura de costura ajustable: hasta 45–50cm |

| Se requiere alta precisión | Tolerancia de costura ≤±1mm, control por servo motor |

| Materiales mixtos | Compatibilidad con tela, cuero y no tejidos |

| Diseño de esquina curva | Sincronización de giro automático de esquina y elevación de aguja |

Table Of Contents For This Page

No es fácil introducir todos los aspectos de la madera personalizada, por lo que hemos preparado mucha información en esta página para que puedas profundizar. Para asegurarnos de que puedas encontrar rápidamente la información que deseas, hemos preparado este índice de contenido que saltará a la ubicación correspondiente cuando hagas clic en él.

Common Questions

Most Popular Questions.

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

We offer both food-grade borosilicate glass and soda-lime glass, each fully tested for thermal shock resistance and chemical stability.

Yes—choose any volume from 4 oz to 32 oz, straight or tapered walls, and clear, amber or any custom tint.

We supply metal screw-on lids (plain or with straw hole), bamboo lids, and plastic snap-on caps—all compatible with our jar neck finish.

Standard MOQ is 500 pcs per SKU. Tiered pricing and volume discounts kick in at 1,000 pcs, 5,000 pcs and above.

Rapid 3–5 day turnaround: includes a 3D render plus a physical prototype, with a refundable fee of USD 50–100.

We run a 12-step QC process—from raw-material inspection through final assembly—ensuring ≥ 99.98 % pass rate on every batch.

Our factory is ISO 9001 and GMP certified, and our jars carry FDA, LFGB and REACH approvals, with full third-party test reports.

Multi-layer protection (EPE foam, honeycomb paper, wooden crates) plus cargo insurance and complete customs documentation for global delivery.