How Fully Automatic Tape Edge Machines Significantly Reduce Labor Dependency

Among all mattress manufacturing processes, tape edging has long been recognized as one of the most labor-dependent, experience-driven, and difficult-to-standardize…

Even in factories where spring production, gluing, and conveying have already been automated, tape edging often remains the section with the highest number of workers, the greatest skill dependency, and the most frequent quality fluctuations.

As labor costs continue to rise, skilled workers become harder to retain, and delivery schedules grow tighter, more mattress manufacturers are re-examining a fundamental question:

Does tape edging really have to rely on people?

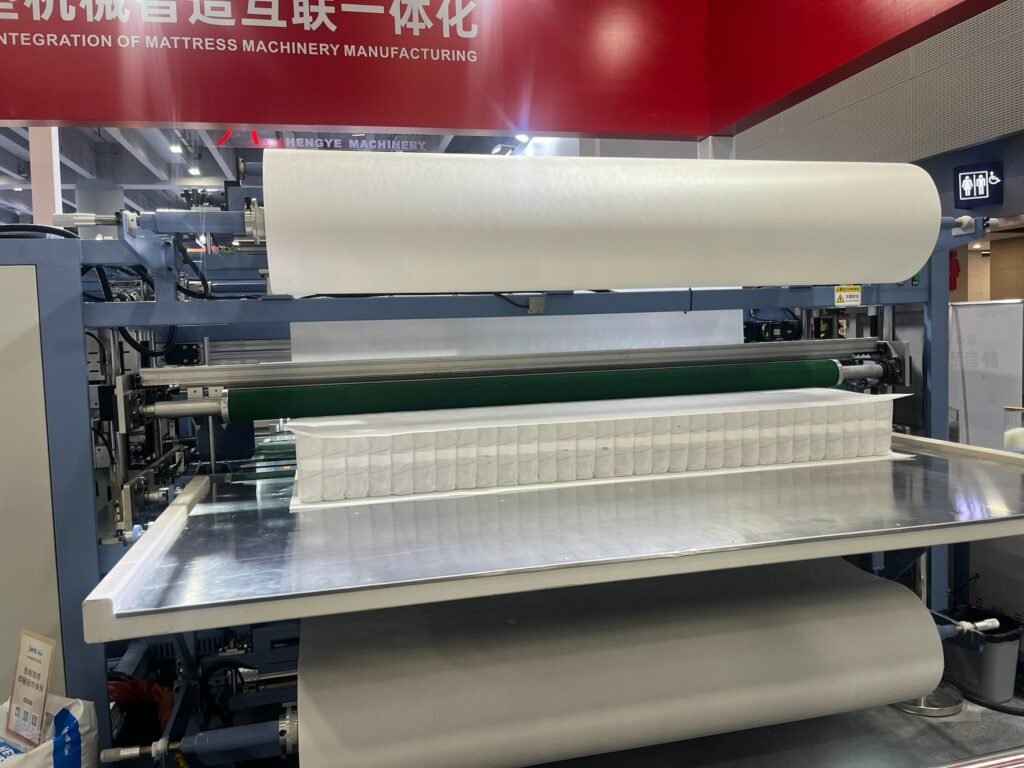

The rapid adoption of fully automatic tape edge machines provides a clear and practical answer. This article explains how fully automatic tape edge machines significantly reduce labor dependency by reshaping production logic, stabilizing process execution, and redefining workforce requirements.

Pour référence aux équipements liés et aux concepts de production intégrés, vous pouvez consulter la page interne de l'entreprise :

https://mattressmachineryzl.com/

Why Tape Edging Has Traditionally Been Highly Labor Dependent

Tape edging is not just a sewing operation. It is a compound process that involves mattress handling, alignment, rotation, corner control, stitching consistency, and visual finish.

In traditional semi-automatic or manual tape edging setups, operators are responsible for:

(1) Lifting and positioning the mattress

(2) Controlling feeding speed and direction

(3) Managing corner transitions

(4) Maintaining stitch quality

(5) Correcting misalignment in real time

Each of these tasks depends heavily on experience. A skilled operator can maintain acceptable quality, while an inexperienced worker may cause defects within minutes. This makes labor dependency unavoidable in traditional systems.

Structural Limitations of Manual and Semi-Automatic Tape Edge Processes

From a production management perspective, manual and semi-automatic tape edging has several inherent limitations.

First, output is directly tied to individual skill.

Production capacity cannot be scaled without adding skilled operators.

Second, quality consistency is difficult to control.

Even within the same shift, results vary between operators.

Third, labor intensity is high.

Operators must physically handle heavy mattresses, increasing fatigue, injury risk, and turnover.

These structural constraints make tape edging a bottleneck not only in capacity, but also in workforce stability.

How Fully Automatic Tape Edge Machines Change the Production Logic

Fully automatic tape edge machines do not simply automate sewing. They fundamentally change how the process is organized.

The core shift is this:

Human operators move from performing the process to supervising the process.

In a fully automatic system:

(1) Mattress feeding is automated

(2) Mattress flipping and rotation are automated

(3) Sewing head movement and angle are controlled by the system

(4) Corner transitions are handled consistently

(5) Stitch speed and tension are automatically regulated

As a result, the machine executes the process, while humans focus on monitoring and exception handling.

Reduction of Skill Dependency Through Process Standardization

One of the most important benefits of full automation is standardization.

In manual tape edging, quality depends on “how the operator feels” at each moment.

In a fully automatic machine, quality depends on parameters.

Once parameters such as stitch length, sewing speed, mattress thickness range, and corner behavior are defined, the machine repeats them consistently.

This dramatically reduces the need for highly experienced operators. New workers can be trained to operate the machine in a much shorter time, and output quality remains stable regardless of individual differences.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

https://mattressmachineryzl.com/

cURL Too many subrequests.

cURL Too many subrequests.

Exigences en main-d'œuvre | Élevé | Significativement réduit

cURL Too many subrequests.

cURL Too many subrequests.

Training time | Long | Short

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

These advantages become increasingly important as mattress markets demand shorter lead times and more consistent quality.

Conclusion: Tape Edging No Longer Has to Depend on People

Tape edging has historically been one of the last strongholds of manual labor in mattress manufacturing. However, fully automatic tape edge machines prove that this dependency is not inevitable.

By standardizing execution, automating handling, stabilizing quality, and reshaping workforce roles, these machines fundamentally reduce reliance on skilled manual labor.

For manufacturers aiming to control costs, improve stability, and scale production sustainably, fully automatic tape edging is not just an equipment upgrade. It is a strategic shift in how production is organized.

In today’s competitive environment, reducing labor dependency is no longer optional. Fully automatic tape edge machines provide a clear and proven path forward.