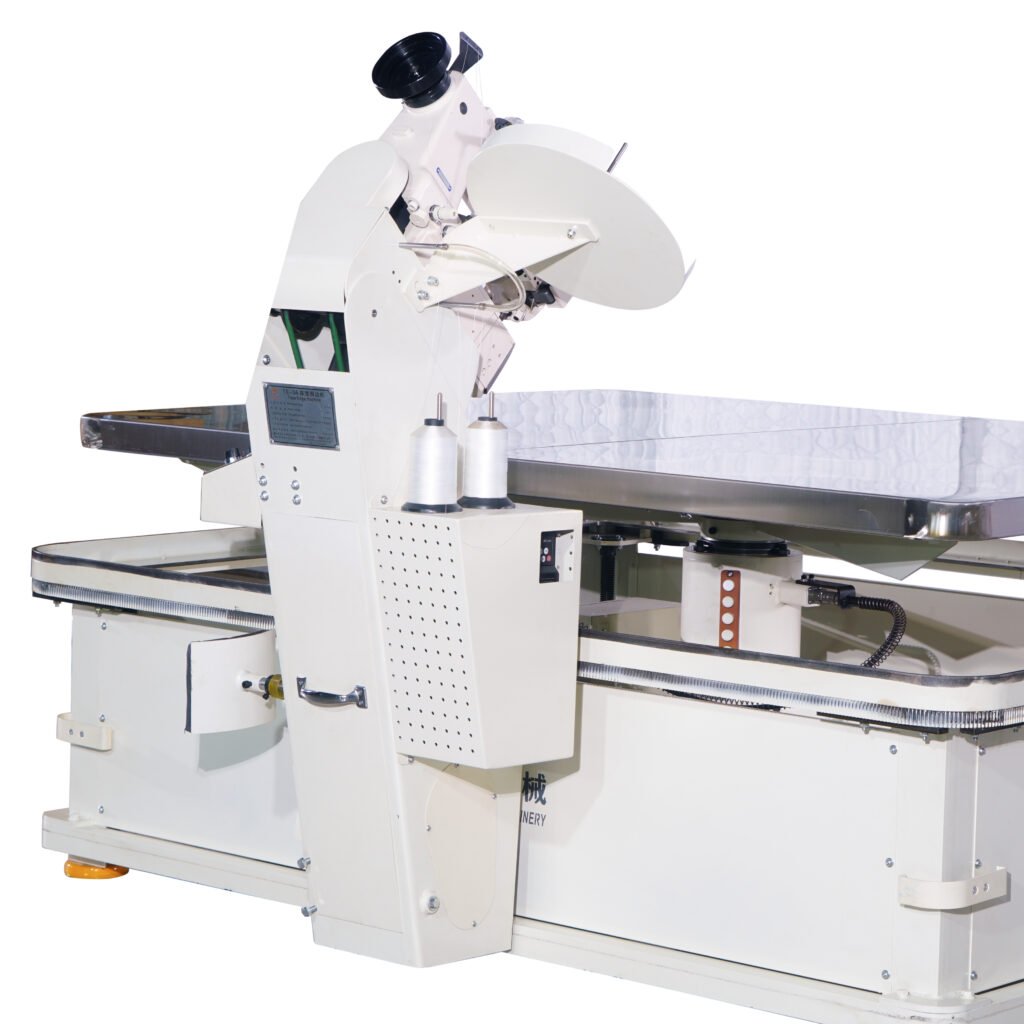

Side Border Straight Sewing Machine + Lockstitch Tape Edge Machine: Building a High-End Mattress Side Border Production Line

In high-end mattress manufacturing, side border quality has become a decisive factor in product positioning. While consumers may not fully understand internal spring structures or foam formulations, they can immediately judge the craftsmanship of a mattress by its side border. Straight stitching accuracy, seam durability, corner finish, and overall visual consistency all contribute directly to […]

For factories targeting mid- to high-end markets, relying on a single machine or a single process is no longer sufficient. A growing number of manufacturers are adopting a combined production line composed of a side border straight sewing machine and a lockstitch tape edge machine. This combination allows each machine to focus on what it does best, creating a structured, efficient, and scalable side border production system.

This article explains how the straight sewing machine and lockstitch tape edge machine work together to build a high-end mattress side border production line, and why this configuration has become a preferred solution for quality-driven factories.

Pour référence aux équipements liés et aux concepts de production intégrés, vous pouvez consulter la page interne de l'entreprise :

https://mattressmachineryzl.com/

Why Side Border Quality Defines High-End Mattress Manufacturing

The side border is not just a decorative element. It performs critical functional and visual roles.

Functionally, it:

- Connects top and bottom panels securely

- Reinforces mattress edges

- Maintains long-term structural integrity

Visually, it:

- Définit la rectitude et la symétrie

- Highlights stitching precision

- Communicates manufacturing quality

In high-end products, even small inconsistencies in the side border can undermine brand perception. This is why advanced manufacturers treat side border production as a dedicated system rather than a single operation.

Limitations of Single-Machine Side Border Solutions

In many traditional factories, side border production relies on one machine to perform multiple tasks. This approach creates inherent compromises.

When one machine attempts to handle straight stitching, pattern formation, and final edge locking:

- Process optimization becomes difficult

- Speed and quality conflict

- Operator intervention increases

- Consistency suffers at scale

As production volume grows, these limitations become more visible. Separating tasks into specialized machines allows higher control and better results.

The Role of the Side Border Straight Sewing Machine

The side border straight sewing machine is designed specifically for long, linear seams along the mattress side panel.

Its primary strengths include:

- Precise straight-line stitching

- Stable seam alignment

- High-speed operation on flat sections

- cURL Too many subrequests.

By focusing solely on straight seams, this machine ensures that the side border panel itself is clean, flat, and dimensionally accurate before final assembly.

This step establishes the foundation for a high-quality side border.

Why Straight Sewing Should Be Isolated as a Dedicated Process

Straight seams are visually dominant. Any waviness or misalignment becomes immediately noticeable once the mattress is assembled.

Isolating straight sewing offers several advantages:

- Higher speed without corner-related slowdowns

- Improved seam straightness

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- Le temps de formation est raccourci

cURL Too many subrequests.

Consistency Across Batches and Shifts

Consistency is one of the biggest challenges in high-end manufacturing.

By dividing the process into specialized stages:

- Straight seams remain consistent across all side panels

- Final assembly behaves predictably

- Quality variation between shifts is reduced

This consistency is critical for factories supplying large retailers or export markets.

Integration into Automated Mattress Production Lines

This two-machine configuration integrates well with modern production lines.

Typical integration includes:

- Automated side panel feeding

- Conveyor transfer between machines

- Automated mattress positioning and flipping

- Downstream packaging systems

This integration reduces manual handling and supports continuous production flow.

Plus d'informations sur les solutions de production intégrée peuvent être trouvées en interne à :

https://mattressmachineryzl.com/

Flexibility for Multiple Product Lines

High-end mattress factories often produce multiple models with different dimensions and designs.

Using two specialized machines allows:

- Faster changeover between specifications

- Independent parameter adjustment

- Better control over visual details

This flexibility supports customization without sacrificing efficiency.

Stabilité de la qualité à long terme et avantages de maintenance

From a maintenance perspective, task separation reduces mechanical stress.

Each machine:

- Operates within a narrower function range

- Experiences less wear from complex motion

- Maintains calibration longer

This improves long-term quality stability and lowers maintenance costs.

Summary Table: Value of a Straight Sewing + Lockstitch Tape Edge Production Line

Production Aspect | Single-Machine Approach | Straight Sewing + Lockstitch Tape Edge Line

Straight seam quality | Variable | Highly consistent

Corner and edge durability | Moderate | Strong and uniform

Production rhythm | Unstable | Stable and predictable

Dépendance à la main-d'œuvre | Élevée | Significativement réduite

Scalability | Limited | High

Integration with automation | Difficult | Seamless

Why This Configuration Fits High-End Manufacturing Strategy

High-end mattress manufacturing prioritizes consistency, durability, and brand image over short-term speed gains.

The straight sewing machine + lockstitch tape edge machine configuration aligns with this strategy by:

- Structuring the process logically

- Reducing reliance on individual skill

- Enabling scalable automation

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.

cURL Too many subrequests.