Single-Wire vs. Dual-Wire Spring Coiling Heads: How to Choose the Best Configuration for Pocket Spring Production

When I work with mattress factories around the world, one of the most common questions I receive is surprisingly practical: “Should we choose a single-wire spring head or a dual-wire spring head for producing pocket springs?” Many factory owners understand the importance of spring quality, output stability, and long-term operating cost, but they are unsure how the choice of coiling head affects these factors. Over the years, after observing dozens of production lines, comparing real performance metrics, and analyzing product requirements, I have developed a clear understanding of what makes each configuration valuable.

Pocket spring manufacturing has become a highly competitive field. As mattress brands push for better ergonomics, higher durability, and more diversified firmness designs, factories must decide whether their production strategy should prioritize speed, flexibility, precision, or structural diversity. The truth is that single-wire and dual-wire configurations each serve different strategic goals—and understanding them clearly can help a factory avoid unnecessary costs, delays, or mismatched equipment purchases.

In the following article, I will present a detailed technical and operational comparison between single-wire and dual-wire spring heads. I will also share stories and observations from real factories, explain how performance requirements shape equipment selection, and offer a complete decision-making framework supported by a practical comparison table. If you are considering an upgrade to your pocket spring production line, this exploration will help you make a more informed and confident choice.

Why the Coiling Head Determines Overall Pocket Spring Production Quality

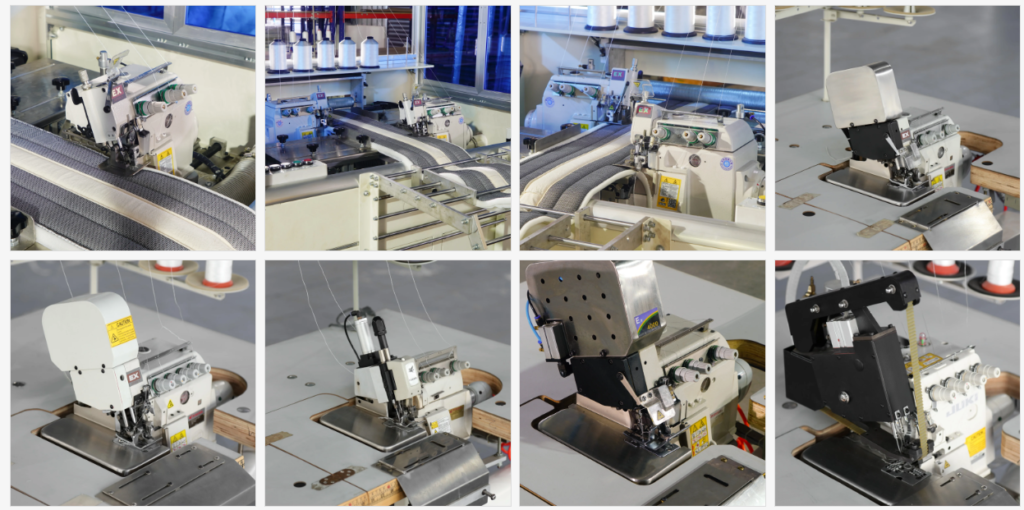

The coiling head is the heart of any pocket spring machine. It defines spring geometry, compression force, deformation resistance, and overall mattress feel. When I audit production lines, I always start by reviewing the coiling setup, because a machine’s performance is only as strong as its coiling precision. The wire feeding, pitch control, cutting rhythm, heat treatment, and twist angle all originate from the coiling head’s engineering.

Pocket springs have become the global standard for mid- to high-end mattress designs. The demand for durable, silent, breathable, and body-adaptive structures continues to rise. As a result, factories need to determine whether they want a standard production line (usually supported by a single-wire head) or a zoned production line (enabled by dual-wire technology). This choice directly determines the product range a factory can provide.

Understanding Single-Wire Spring Coiling Heads

Single-wire spring heads use one continuous wire to form springs one after another. This configuration is the most widely used globally because of its simplicity, stability, and excellent cost-performance ratio. Across most factories I have worked with, single-wire heads represent the baseline equipment for any pocket spring workshop.

Here are the core advantages I typically observe in single-wire systems:

(1)High stability during long production cycles

Single-wire setups are mechanically simpler, resulting in fewer adjustments and lower failure rates. Factories producing high-volume standard mattresses greatly benefit from this reliability.

(2)Lower material cost and fewer wire-change interruptions

A single spool of wire is easier to manage than two. This reduces downtime and simplifies inventory control.

(3)Straightforward operation and easier training for new staff

The learning curve is gentle, making it ideal for factories operating in regions with high staff turnover.

(4)Strong compatibility with mainstream mattress products

Most Bonnell-like pockets, standard cylindrical springs, and entry-level to mid-range pocket spring units rely on this structure.

However, single-wire heads also reveal certain limitations:

- They cannot efficiently produce zoned mattress structures.

- They offer limited control over variable firmness across the same spring unit.

- They are less suited for premium mattress brands requiring differentiated support zones.

Despite these constraints, single-wire heads remain the optimal solution for factories prioritizing cost control and mass production.

Understanding Dual-Wire Spring Coiling Heads

Dual-wire spring heads feed two wires into the coiling process, allowing the machine to alternate between wire diameters or characteristics during production. This design supports advanced spring structures, especially those used in luxury mattresses. I often recommend dual-wire systems to factories targeting premium export markets or focusing on ergonomics and differentiated firmness.

The key advantages include:

(1)Ability to produce zoned pocket spring structures

This is the biggest advantage. Different zones can be designed with different wire thicknesses to provide enhanced lumbar support, softer shoulder comfort, or reinforced edge support.

(2)Greater customization and engineering flexibility

Because each wire has independent control settings, factories can craft a more sophisticated comfort profile.

(3)Higher product premium value

Products made using dual-wire systems often command higher market prices.

(4)Better adaptation to modern mattress trends

Hybrid mattresses, multi-layer support systems, and ergonomic designs increasingly require variable firmness zones.

Still, dual-wire systems also bring notable challenges:

- They require more experienced operators.

- Wire feeding, tension balancing, and changeover adjustments are more complex.

- Material waste can increase if not properly configured.

- The upfront investment is higher than single-wire equipment.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|---|

| Production Speed | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | More complex | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Maintenance Frequency | cURL Too many subrequests. | Medium to high | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | High-volume manufacturers | Premium, export-oriented brands | Aligns with market position |

Dive Deeper: How Market Strategy Influences Equipment Selection

When I advise a factory on equipment upgrades, I rarely start with machinery specifications. Instead, I begin by understanding their product strategy, customer base, and long-term growth trajectory. The decision between single-wire and dual-wire systems is not just a technical choice—it is a strategic one.

Factories prioritizing predictable production, cost control, and stable mid-range output benefit most from single-wire systems. Their business model depends on volume and efficiency, not on differentiated product features. Their customers often include large retailers, regional mattress brands, and OEM buyers seeking competitive pricing.

Factories targeting international markets, hotel contracts, or luxury brand partnerships gain far more value from dual-wire systems. These clients expect zone-specific support, graphene-infused comfort layers, and hybrid structures combining foam, springs, and latex. Dual-wire production enables factories to meet these advanced requirements without outsourcing spring structures or relying on pre-made imports.

Moreover, the long-term profitability of dual-wire lines often comes from product diversification, not volume. A factory can offer dozens of new SKUs simply by adjusting wire diameters, spring heights, and zoning configurations—without modifying other production stages.

In many cases, dual-wire capability becomes the foundation for expanding into new market tiers.

Dive Deeper: Operational Considerations That Are Often Overlooked

Here are some practical insights that factory owners often neglect when deciding between single-wire and dual-wire equipment:

(1)Factory staffing impacts ROI more than most people realize

Dual-wire systems require experienced technicians. If a factory struggles with talent retention, the complexity may cause long-term inefficiencies.

(2)Production line layout may need adjustment for dual-wire workflows

Wire feeding, spool storage, and tension monitoring stations require more space.

(3)Spring uniformity affects the entire downstream process

Even small inconsistencies in dual-wire products can slow down gluing, assembly, and packing stages.

(4)Product branding can justify higher equipment investment

Premium mattresses produced on dual-wire systems often support stronger brand storytelling, especially in international markets.

(5)Consumer trends are shifting toward ergonomic designs

Factories that fail to adopt zoning technologies risk losing market share in the medium to long term.

These deeper operational insights help clarify the long-term impact of equipment investment decisions.

Conclusion: How to Make the Right Choice for Your Factory

After comparing mechanical structure, production efficiency, operator requirements, and market strategy, I believe the choice between single-wire and dual-wire spring coiling heads can be summarized clearly:

Choose single-wire if your factory prioritizes:

- cURL Too many subrequests.

- Operational stability

- Low cost of ownership

- Simple maintenance

- Standard mattress models

Choose dual-wire if your factory prioritizes:

- Premium product development

- Zoned mattress structures

- Market differentiation

- Higher profit margins

- Advanced ergonomic support systems

Both configurations have their own strengths. The “best” equipment is the one that aligns with your factory’s goals, customer expectations, and long-term development strategy.

If your factory aims to scale production quickly, single-wire is the ideal choice.

If your factory aims to lead in product innovation, dual-wire is the strategic solution.