Mattress Packaging Production Line

Sofa Compression Roll Machines

How Compact Can Packages Get?

The size of the final package really depends on the specific sofa, but in general, this roll cage machine can compress sofas down to diameters as slim as 9.5 inches, and up to 13.5 inches. The width of the resulting package will, of course, match whatever width your sofa started with—no sneaky shrinking on that front. Just think: your massive sectional could potentially become as easy to maneuver as a rolled-up area rug.

Instead of flat-packing, the roll cage system takes each sofa as it is and compresses it while gently rotating. As the sofa moves through the machine, layers of stretch film are applied, forming a tight, protective wrap around the product. The process is simple: the product enters, is compressed and rotated inside the cage, and emerges fully packaged in stretch film—ready for handling and transport.

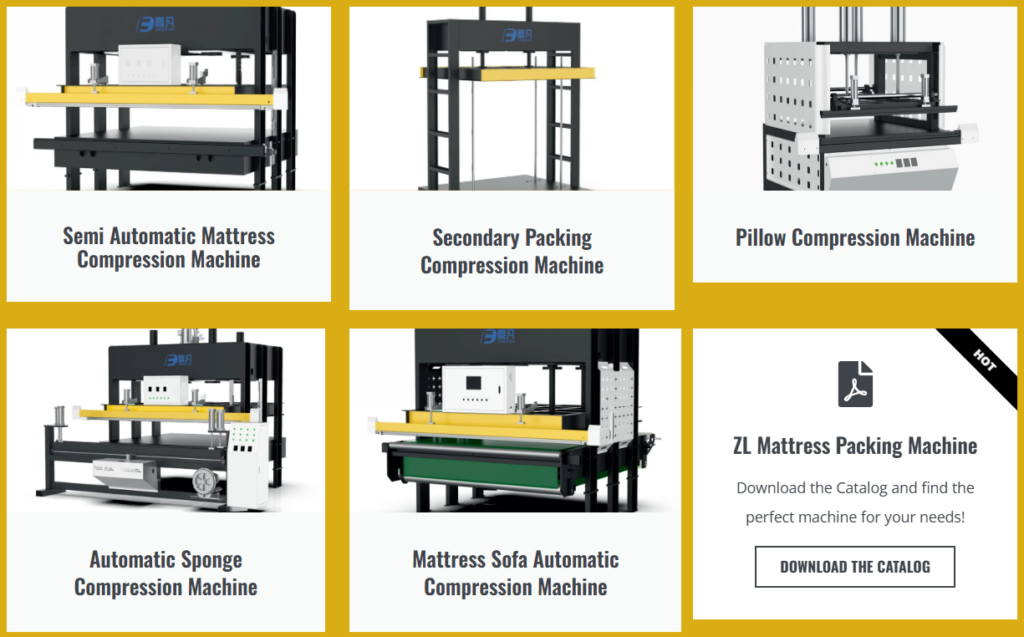

Mattress & Pillow Compression Machines

Mattress & Pillow Compression Machines

Perfect Fit for Versatile Foam Product Packaging

If you’re searching for a flexible, cost-effective solution for rolling and packaging foam-based products, this machine fills the bill. Designed for manufacturers aiming to streamline operations without the need for full press-and-fold machinery, it shines across a variety of industries and product types.

Applications and Product Types

This packaging equipment is particularly well-suited for:

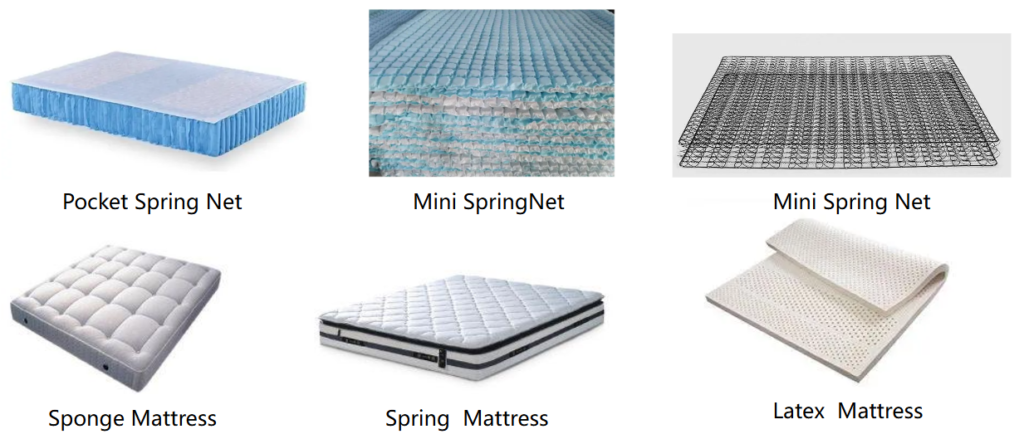

- Foam and latex mattresses

- Foam toppers (both standard beds and specialty items)

- Innerspring mattresses

- Foam cores and plates

- Small beds and pet mattresses

- Wedges, cushions, and similar foam goods

Industries Served

You’ll find this solution valued by companies within:

- Mattress manufacturers (both large-scale and boutique brands)

- Custom bedding producers

- Furniture makers (including those creating sofa-beds or compact sleeping solutions)

- E-commerce retailers specializing in “bed-in-a-box” shipping

- Warehousing and logistics providers needing compact storage options

Whether you’re shipping across the country for a major retailer or storing product for your online shop, this machine reliably creates tightly rolled packages with diameters that fit storage, shipping, and retail efficiency. It’s the ideal choice for businesses seeking performance without unnecessary complexity.

Key Features of the Roll Cage Packaging Machine

Our roll cage packaging machine streamlines mattress packing with several smart features designed for efficiency and ease:

- Stretch Film Wrapping: Products are automatically encapsulated in stretch film, tightly wrapping them as they travel through the rollers—ensuring a secure, protective layer without extra packing steps.

- Integrated Compression & Rolling: The machine gently compresses and rolls each mattress in a single motion, eliminating the need for pre-flattening. This process reduces product volume and prepares it for simple, compact shipping.

- Compact Package Sizes: Final rolled diameters typically range from 9.5 to 13.5 inches (241–343 mm), making products easy to handle and ideal for boxed shipping—especially when paired with a boxline accessory.

- High Throughput: Designed for busy production lines, the machine can process over 120 packages per hour to keep up with demand.

- Adaptable Footprint: Standard setup measures about 13 ft x 11.5 ft x 8 ft (4 m x 3.5 m x 2.4 m), supporting efficient use of factory floor space.

- Versatile Product Range: Perfect for packaging foam mattresses, innersprings, foam cores, latex toppers, smaller beds, pet mattresses, and more.

- Ideal for Multiple Uses: The resulting packages are suitable for warehousing, retail shelves, shipping, and e-commerce fulfillment, helping you reach customers however they shop.

Whether you’re looking to improve shipping efficiency or maximize storage, this roll cage solution offers flexibility, speed, and reliability in every package.