The Intelligent Upgrade Path for Mattress Manufacturing Factories

In the global mattress industry, competition is no longer driven only by product design or raw material selection. It is increasingly shaped by manufacturing capability. Rising labor costs, growing product complexity, shorter delivery cycles, and higher quality expectations are forcing mattress factories to rethink how they operate.

An intelligent upgrade is not a single equipment purchase or a sudden transformation. It is a structured, step-by-step evolution that reshapes production logic, workforce roles, and factory architecture over time. Factories that approach intelligent upgrading systematically gain sustainable advantages, while those that rely on fragmented automation often struggle with instability and rising costs.

This article outlines a practical and realistic intelligent upgrade path for mattress manufacturing factories, based on production flow, automation logic, and long-term operational goals rather than abstract digital concepts.

For reference to relevant equipment and integrated production solutions, you may consult the internal company page:

https://mattressmachineryzl.com/

Understanding What “Intelligent Manufacturing” Means in Mattress Production

Intelligent manufacturing in mattress factories does not mean replacing every worker with machines or implementing complex IT systems overnight. In practical terms, it means:

- Reducing dependence on manual judgment

- Embedding consistency into processes

- Connecting individual machines into coordinated systems

- Allowing production to adapt automatically to change

The goal is stable, predictable, and scalable production, not maximum automation for its own sake.

Stage One: Stabilizing Core Production Processes

The first step in intelligent upgrading is process stabilization.

Many factories attempt to automate before their processes are stable. This leads to automation amplifying existing problems rather than solving them.

At this stage, factories should focus on:

- Standardizing operating parameters

- Eliminating excessive manual adjustment

- Reducing quality variation between shifts

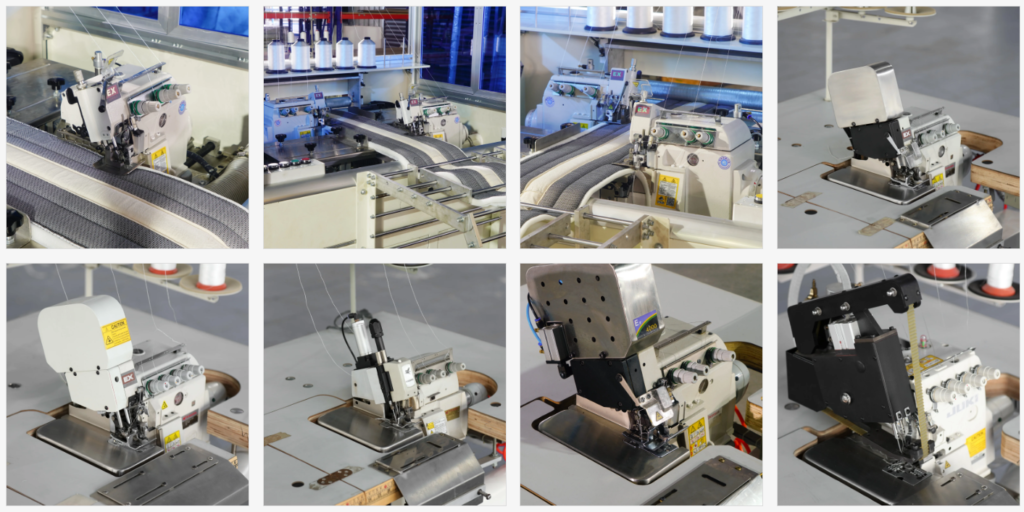

Key equipment upgrades often include:

- More stable sewing and tape edge machines

- Controlled glue spraying systems

- Accurate cutting and feeding equipment

Stability is the foundation. Without it, higher-level automation cannot succeed.

Stage Two: Replacing High-Intensity Manual Handling

Once core processes are stable, the next upgrade priority is material handling.

Manual handling consumes large amounts of labor and creates safety risks. It also introduces inconsistency and limits production speed.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. real-time decision support.

Key developments include:

- Monitoring equipment status and utilization

- Tracking production rhythm and downtime

- Identifying recurring bottlenecks

This data supports continuous improvement rather than reactive troubleshooting.

Stage Eight: Supporting 24-Hour Continuous Operation

True intelligent manufacturing enables stable round-the-clock operation.

This requires:

- cURL Too many subrequests.

- Predictable machine behavior

- Automated handling and storage

- Reliable fault detection

Factories at this stage can run night shifts with minimal staff, maximizing asset utilization and reducing unit production cost.

Workforce Transformation as Part of the Upgrade Path

Intelligent upgrading does not eliminate the workforce. It transforms it.

As automation increases:

- Physical labor decreases

- Monitoring and coordination roles increase

- Skill requirements shift from manual execution to system understanding

Successful factories invest in retraining rather than replacement, ensuring that human experience complements automated systems.

Avoiding Common Pitfalls in Intelligent Upgrading

Many intelligent upgrade projects fail due to:

- Automating unstable processes

- Purchasing isolated equipment without system planning

- Underestimating integration complexity

- Ignoring operator training

A successful upgrade follows a logical sequence, not a checklist.

Intelligent Upgrading Is a Continuous Journey

There is no final stage where a factory becomes “fully intelligent.”

Markets change. Products evolve. Technology advances.

An intelligent factory is one that can:

- Adapt without major disruption

- Scale capacity without linear labor growth

- Maintain quality under increasing complexity

This adaptability is the true measure of intelligence.

Summary Table: Intelligent Upgrade Path for Mattress Manufacturing Factories

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

More information about integrated production concepts can be found internally at:

https://mattressmachineryzl.com/

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.

cURL Too many subrequests.