How the ZL-AHG Glue Spraying Machine Achieves Strong and Uniform Glue Point Distribution

In modern mattress manufacturing, glue spraying is no longer a simple auxiliary step. It has become a core structural process that directly affects bonding strength, durability, comfort consistency, and long-term product reliability. As mattress structures become more complex and production speeds continue to rise, factories increasingly demand glue spraying equipment that can deliver strong adhesion and highly uniform glue point distribution under continuous operation.

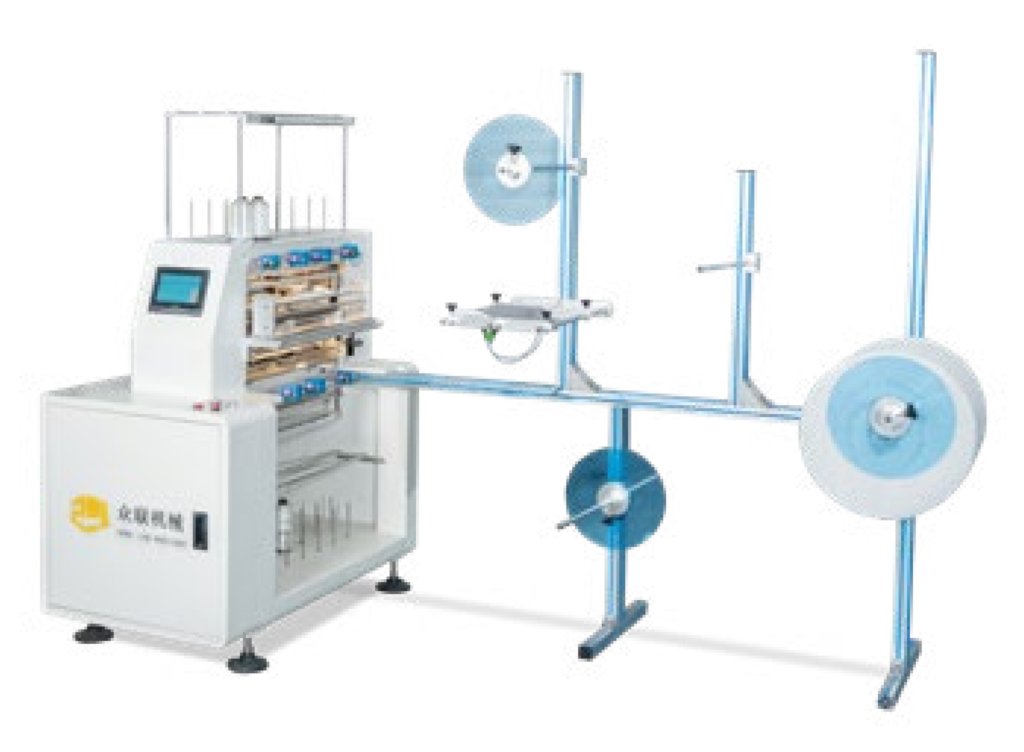

Chiều cao của ZL-AHG Automatic Glue Spraying Machine was developed precisely to address these requirements. It combines servo-driven control, PLC-based logic, laser measurement, and optimized nozzle configuration to ensure that every glue point is accurately placed, evenly distributed, and consistently bonded.

This article provides a comprehensive technical and process-level analysis of how the ZL-AHG achieves strong and uniform glue point distribution, focusing on real manufacturing challenges rather than theoretical descriptions.

Related equipment and production line integration concepts can be referenced internally at:

https://mattressmachineryzl.com/

Why Glue Point Quality Determines Mattress Structural Performance

Glue points are responsible for transferring load, maintaining layer alignment, and preventing internal movement between springs, foam, padding, and fabric layers. When glue distribution is uneven, several problems emerge:

- Localized weak bonding zones

- Excessive glue buildup causing hard spots

- Material delamination after repeated compression

- Increased adhesive consumption and cleaning frequency

Strong and uniform glue points ensure that force is distributed evenly across the mattress structure, preserving comfort and durability over years of use.

Challenges Faced by Conventional Glue Spraying Systems

Traditional glue spraying systems often rely on fixed nozzle positions and mechanical timing. While functional at low speeds, these systems struggle in modern production environments due to:

- Variations in mattress width and thickness

- Material movement during conveying

- Inconsistent spray distance

- Limited adaptability to different product specifications

As production speed increases, these issues lead to unstable glue patterns and inconsistent bonding quality.

Design Philosophy Behind the ZL-AHG Glue Spraying Machine

The ZL-AHG is designed around one central principle: measured control instead of assumed positioning. Rather than spraying glue based on preset mechanical coordinates, the system continuously adapts to real product dimensions and position.

This philosophy is implemented through:

- Laser measurement of incoming materials

- PLC-controlled logic for dynamic adjustment

- Servo-driven glue gun positioning

- Optimized nozzle distribution

Each component contributes to precise glue placement and uniform strength.

Laser Measurement as the Foundation of Accuracy

One of the defining features of the ZL-AHG is its laser measurement system. Before glue spraying begins, the machine measures:

- Actual mattress width

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests., cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- Smooth acceleration and deceleration

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests., cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

Supporting High-Speed Continuous Production

In high-output factories, glue spraying must remain stable during continuous operation.

The ZL-AHG is designed for:

- 15–20 seconds per surface processing

- Stable performance during long shifts

- Seamless integration into automated lines

Its servo and PLC architecture ensures that accuracy is maintained even at elevated speeds.

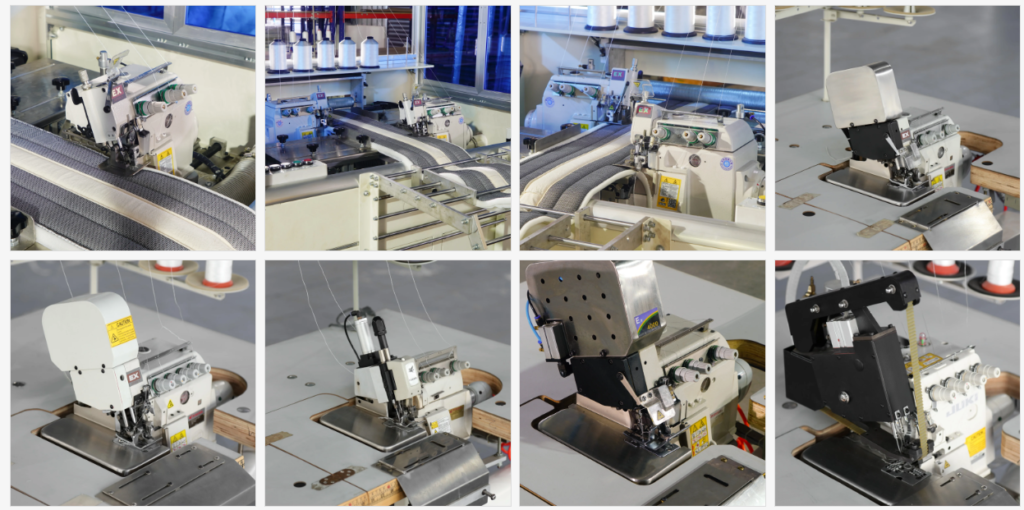

Integration with Mattress Production Lines

The ZL-AHG can be directly connected to automated mattress production lines, including conveying, alignment, and pressing systems.

Integrated operation allows:

- Synchronized material flow

- Reduced handling time

- Improved process consistency

This integration is essential for factories pursuing full automation and standardized quality.

cURL Too many subrequests.

Traditional glue spraying often relies on operator experience for nozzle adjustment and troubleshooting.

With the ZL-AHG:

- Measurement and alignment are automatic

- Spray parameters are stored and recalled

- Operator intervention is minimal

This reduces human variability and ensures consistent quality across shifts.

Process Stability Over Long Production Cycles

Uniform glue point distribution must remain stable not just initially, but over weeks and months of operation.

The ZL-AHG enhances long-term stability by:

- Reducing nozzle clogging through controlled output

- Minimizing mechanical wear with servo motion

- Maintaining calibration through software control

This stability directly improves production uptime and reduces maintenance costs.

Glue Point Strength and Mattress Durability

Uniform glue points distribute load evenly when the mattress is compressed repeatedly.

cURL Too many subrequests.

- Reduced internal layer movement

- Lower risk of delamination

- Longer product lifespan

Strong and evenly distributed glue points are therefore a structural requirement, not just a cosmetic one.

Summary Table: How the ZL-AHG Ensures Strong and Uniform Glue Distribution

Aspect | Conventional Systems | ZL-AHG Glue Spraying Machine

Glue positioning | Fixed mechanical setting | Laser-measured dynamic positioning

Control system | Manual or semi-automatic | PLC + servo closed-loop control

Glue point uniformity | Variable | Highly consistent

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.