ZL is a leading manufacturer of mattress machinery with 15+ years of experience. Our 20,000+ m² factory and 80+ R&D experts enable us to deliver customized, efficient solutions to 2000+ global clients in 150+ countries.

Over 27 Years of Expertise

Mattress Machine Factory

Since 1998

» Customized Solutions Tailored for Diverse Production

»NeedsVersatile Equipment for Smart, Efficient, and Sustainable Mattress Manufacturing

»Globally Trusted Quality for Seamless Market Access»

About Mattress Machine Factory ZL

Mattress Machinery ZL is a leading manufacturer of high-precision mattress production equipment in China. Serving over 500 clients in 30+ countries, we provide efficient, reliable machinery that ensures consistent product quality.

Focused on sustainability, we design energy-saving, eco-friendly machines and offer ODM/OEM customization along with 24/7 technical support.

Choose Mattress Machinery ZL for smart, efficient, and green mattress manufacturing solutions.

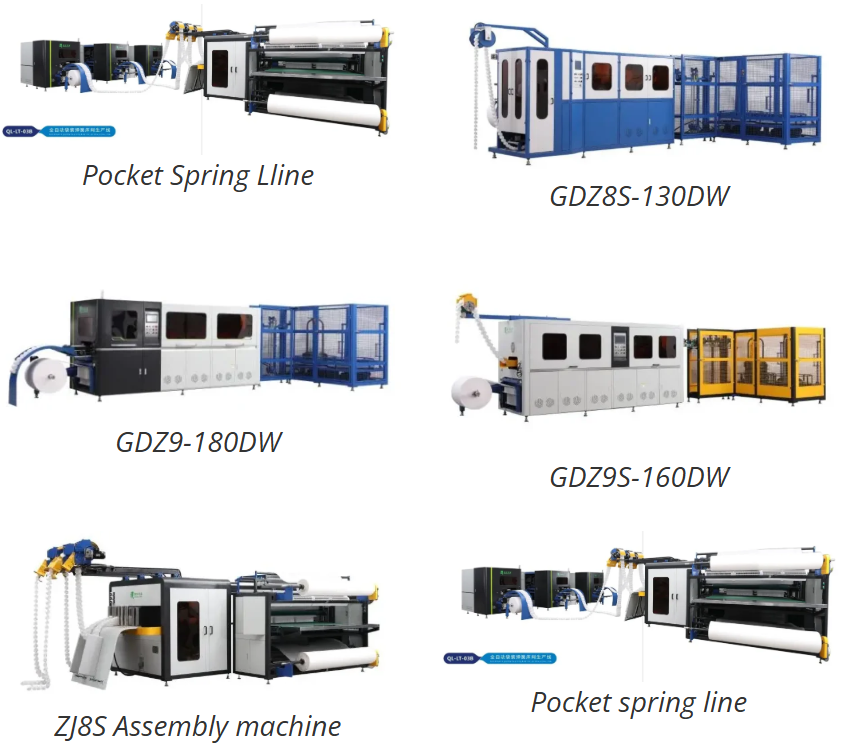

Mattress Spring Machine

Explore our full range of pocket spring machines designed for various production needs:

Pocket Spring Coiling Machines: Including Mini2, GDZ9CE-89/89DW, GDZ9C-180/180DW, and high-compression models like GDZ9HU-63/63DW, delivering precise and efficient spring forming.

Assembly Machines: Fully automatic and semi-automatic pocket spring assembly machines for fast, accurate spring unit assembly.

Gluing Machines: Models such as Z18S/SE/H-400 and Z1R ensure strong, consistent bonding of pocket springs.

Our solutions cover everything from single machines to complete automated production lines, enabling you to choose the right setup for high-capacity or flexible mattress spring manufacturing.

Custom Pocket Spring Machine

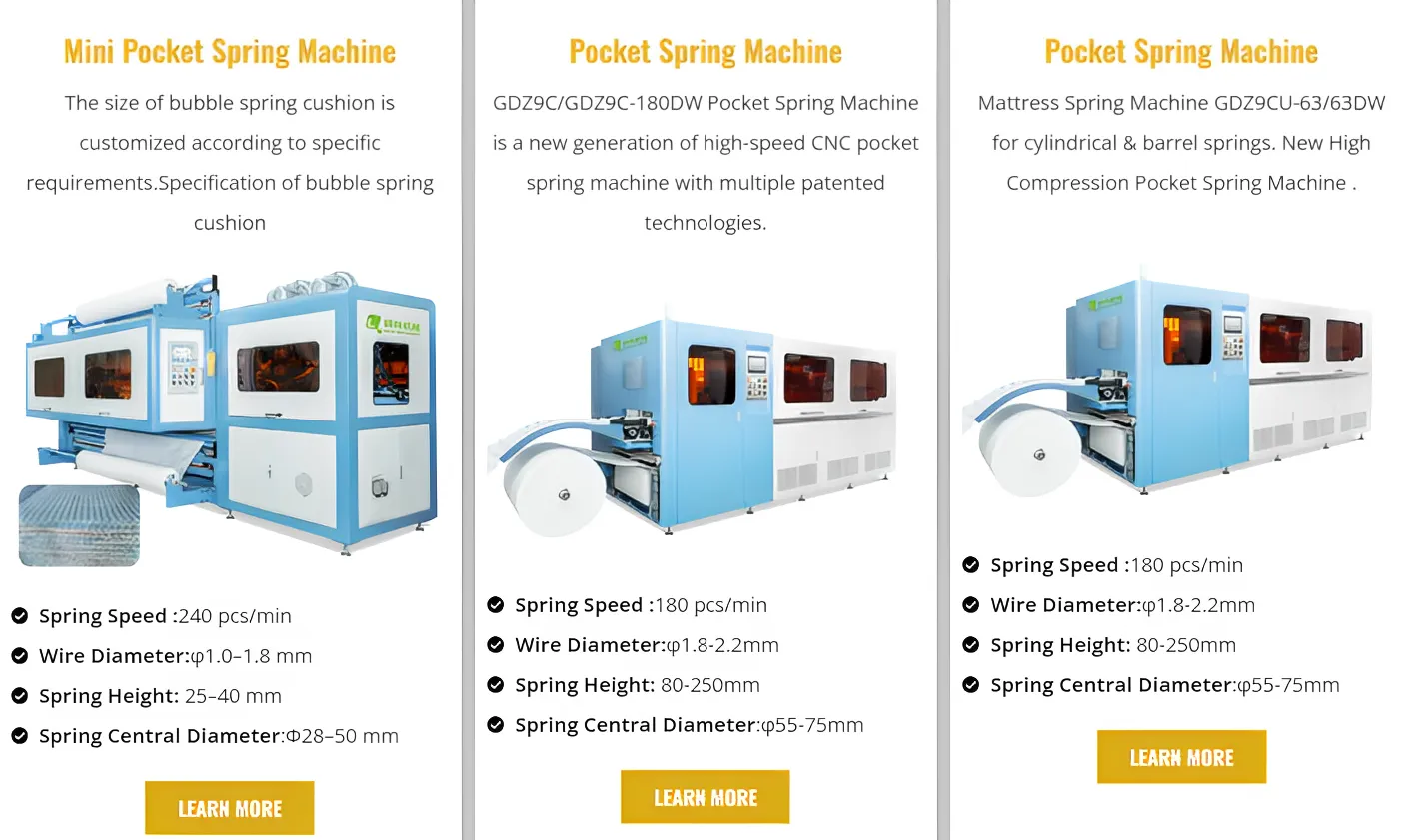

Mini Pocket Spring Machine

The size of bubble spring cushion is customized according to specific requirements.Specification of bubble spring cushion

- Spring Speed :240 pcs/min

- Wire Diameter:φ1.0–1.8 mm

- Spring Height: 25–40 mm

- Spring Central Diameter:Φ28–50 mm

Pocket Spring Machine

GDZ9C/GDZ9C-180DW Pocket Spring Machine is a new generation of high-speed CNC pocket spring machine with multiple patented technologies.

- Spring Speed :180 pcs/min

- Wire Diameter:φ1.8-2.2mm

- Spring Height: 80-250mm

- Spring Central Diameter:φ55-75mm

Pocket Spring Machine

Mattress Spring Machine GDZ9CU-63/63DW for cylindrical & barrel springs. New High Compression Pocket Spring Machine .

- Spring Speed :180 pcs/min

- Wire Diameter:φ1.8-2.2mm

- Spring Height: 80-250mm

- Spring Central Diameter:φ55-75mm

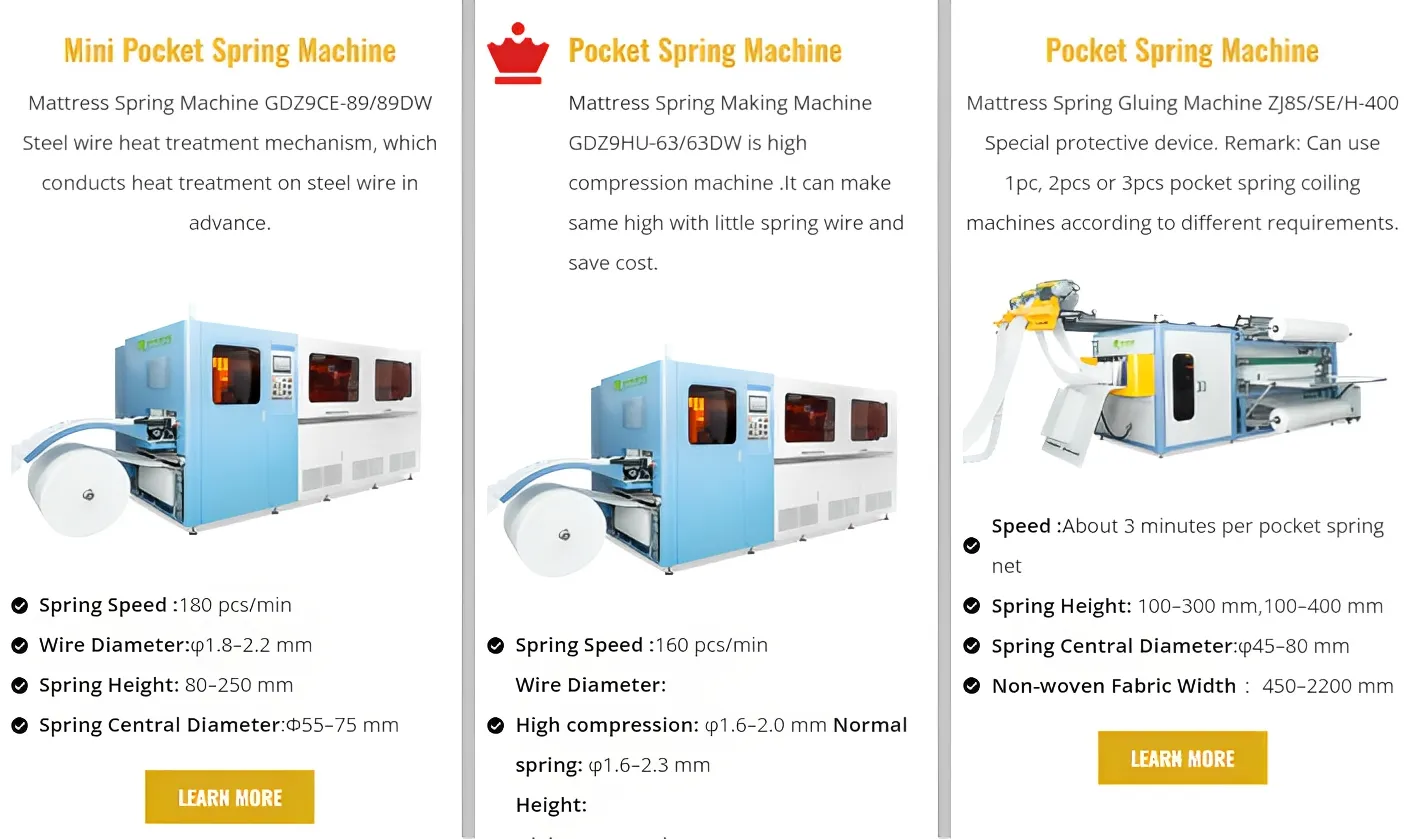

Mini Pocket Spring Machine

Mattress Spring Machine GDZ9CE-89/89DW Steel wire heat treatment mechanism, which conducts heat treatment on steel wire in advance.

- Spring Speed :180 pcs/min

- Wire Diameter:φ1.8–2.2 mm

- Spring Height: 80–250 mm

- Spring Central Diameter:Φ55–75 mm

Pocket Spring Machine

Mattress Spring Making Machine GDZ9HU-63/63DW is high compression machine .It can make same high with little spring wire and save cost.

- Spring Speed :160 pcs/min

-

Wire Diameter:

High compression: φ1.6–2.0 mm Normal spring: φ1.6–2.3 mm -

Height:

High compression: 150–200 mm

Normal spring: 100–240 mm (customizable) - Spring Central Diameter:φ55-75mm

Pocket Spring Machine

Mattress Spring Gluing Machine ZJ8S/SE/H-400 Special protective device. Remark: Can use 1pc, 2pcs or 3pcs pocket spring coiling machines according to different requirements.

- Speed :About 3 minutes per pocket spring net

- Spring Height: 100–300 mm,100–400 mm

- Spring Central Diameter:φ45–80 mm

- Non-woven Fabric Width :450–2200 mm

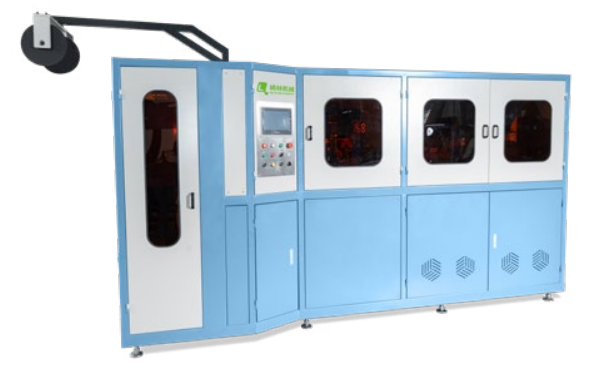

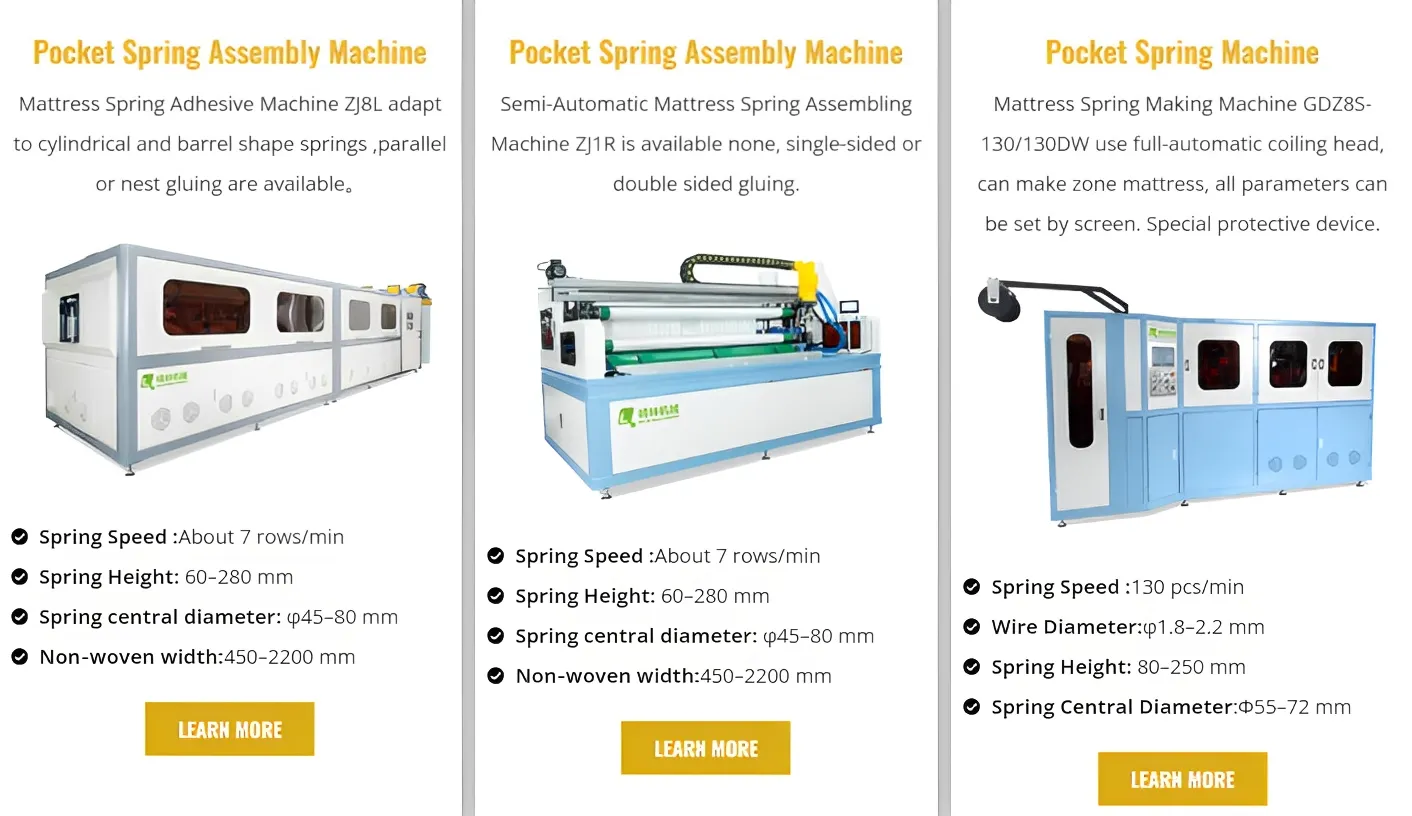

Pocket Spring Assembly Machine

Mattress Spring Adhesive Machine ZJ8L adapt to cylindrical and barrel shape springs ,parallel or nest gluing are available。

- Spring Speed :About 7 rows/min

- Spring Height: 60–280 mm

- Spring central diameter: φ45–80 mm

- Non‑woven width:450–2200 mm

Pocket Spring Assembly Machine

Semi-Automatic Mattress Spring Assembling Machine ZJ1R is available none, single-sided or double sided gluing.

- Spring Speed :About 7 rows/min

- Spring Height: 60–280 mm

- Spring central diameter: φ45–80 mm

- Non‑woven width:450–2200 mm

Pocket Spring Machine

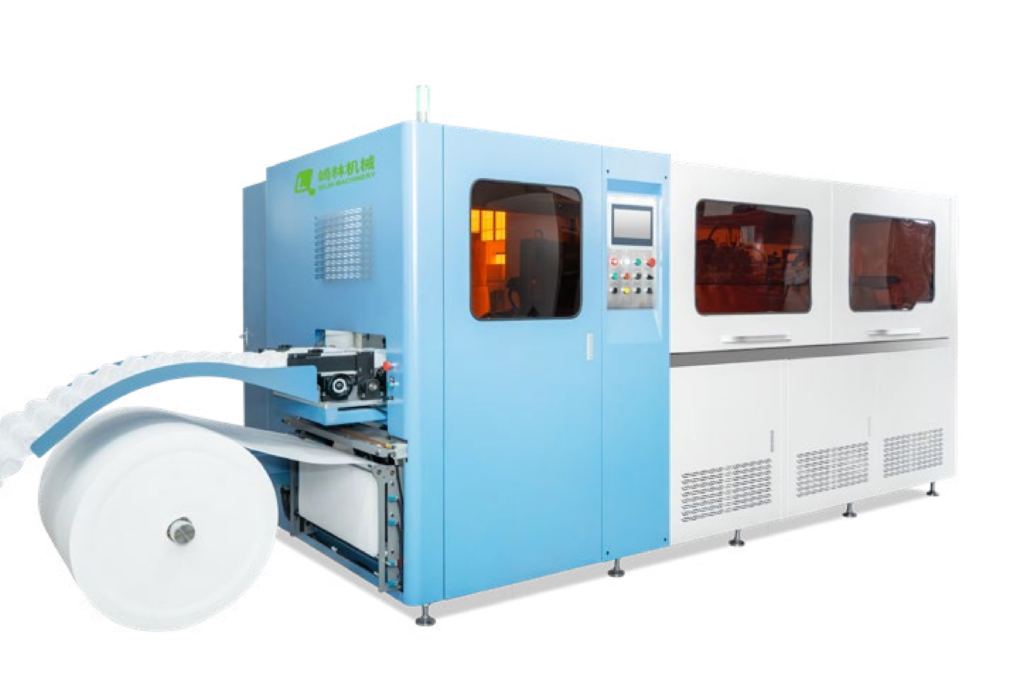

Mattress Spring Making Machine GDZ8S-130/130DW use full-automatic coiling head, can make zone mattress, all parameters can be set by screen. Special protective device.

- Spring Speed :130 pcs/min

- Wire Diameter:φ1.8–2.2 mm

- Spring Height: 80–250 mm

- Spring Central Diameter:Φ55–72 mm

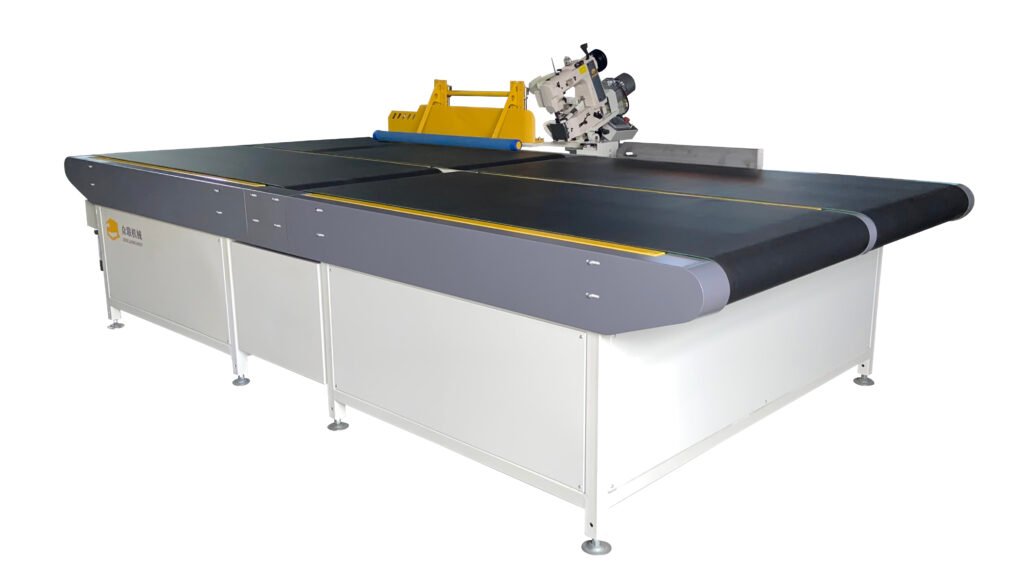

Border & Sewing Machinery Overview

Discover our range of efficient mattress border and sewing machines:

Tape Edge Machines: Automatic and semi-automatic tape edge machines for fast, precise edging.

Label & Handle Machines: Automatic label and handle sewing for finishing touches.

Long Arm & Flat Sewing Machines: High-speed single needle and flat sewing machines for versatile stitching.

Special Systems: Automatic tape and zip systems for streamlined production.

Find the right equipment to enhance your mattress border and sewing process with ease.

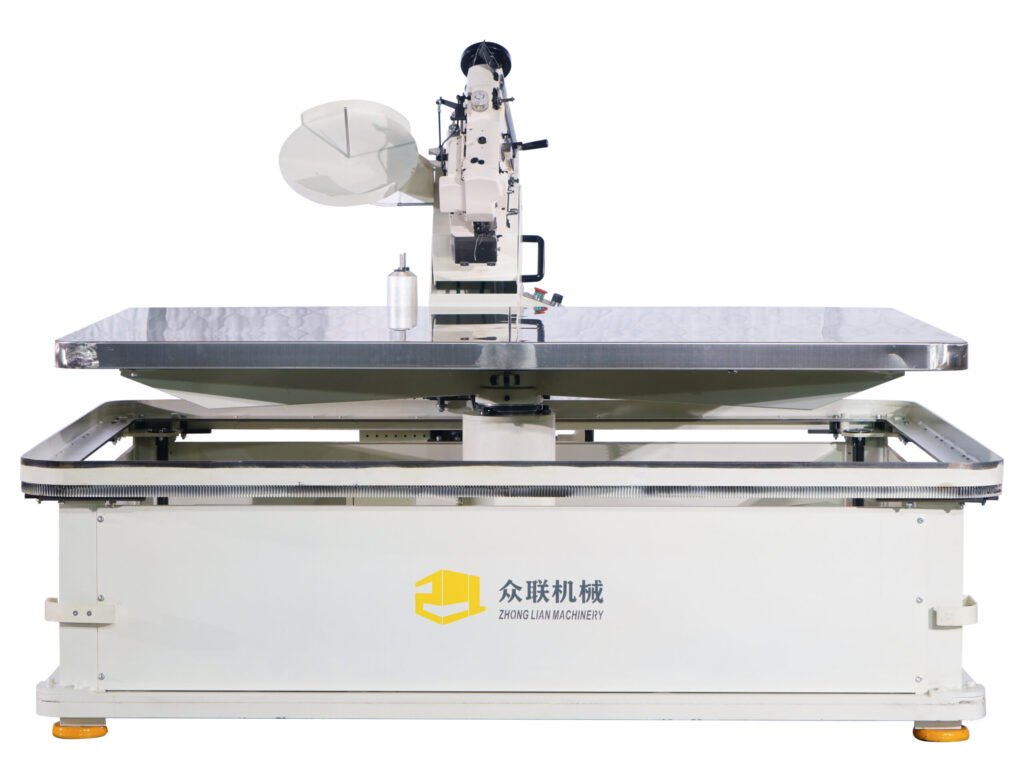

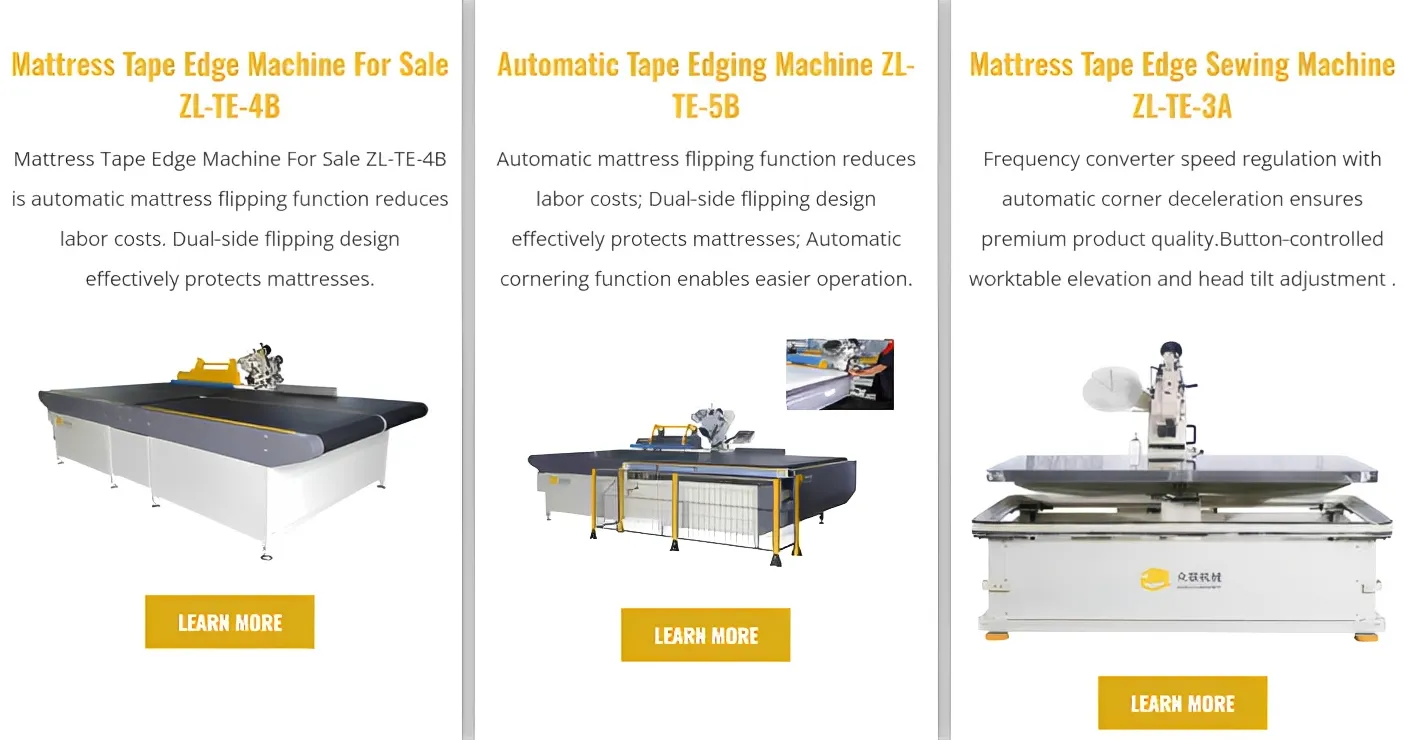

Tape Edge Machine

Mattress Tape Edge Machine For Sale ZL-TE-4B

Mattress Tape Edge Machine For Sale ZL-TE-4B is automatic mattress flipping function reduces labor costs. Dual-side flipping design effectively protects mattresses.

- Speed :15–20 sheets/hour

- Sewing thickness:50–450 mm

- Maximum speed:2800 RPM

- Stitch length:3–7 mm

Automatic Tape Edging Machine ZL-TE-5B

Automatic mattress flipping function reduces labor costs; Dual-side flipping design effectively protects mattresses; Automatic cornering function enables easier operation.

- Speed :15–20 sheets/hour

- Sewing thickness:50–450 mm

- Maximum speed:2800 RPM

- Stitch length:3–7 mm

Mattress Tape Edge Sewing Machine ZL-TE-3A

Frequency converter speed regulation with automatic corner deceleration ensures premium product quality.Button-controlled worktable elevation and head tilt adjustment .

- Speed :10–15 sheets/hour

- Sewing thickness:30–450 mm

- Maximum speed:2800 RPM

- Head lifting range:280 mm

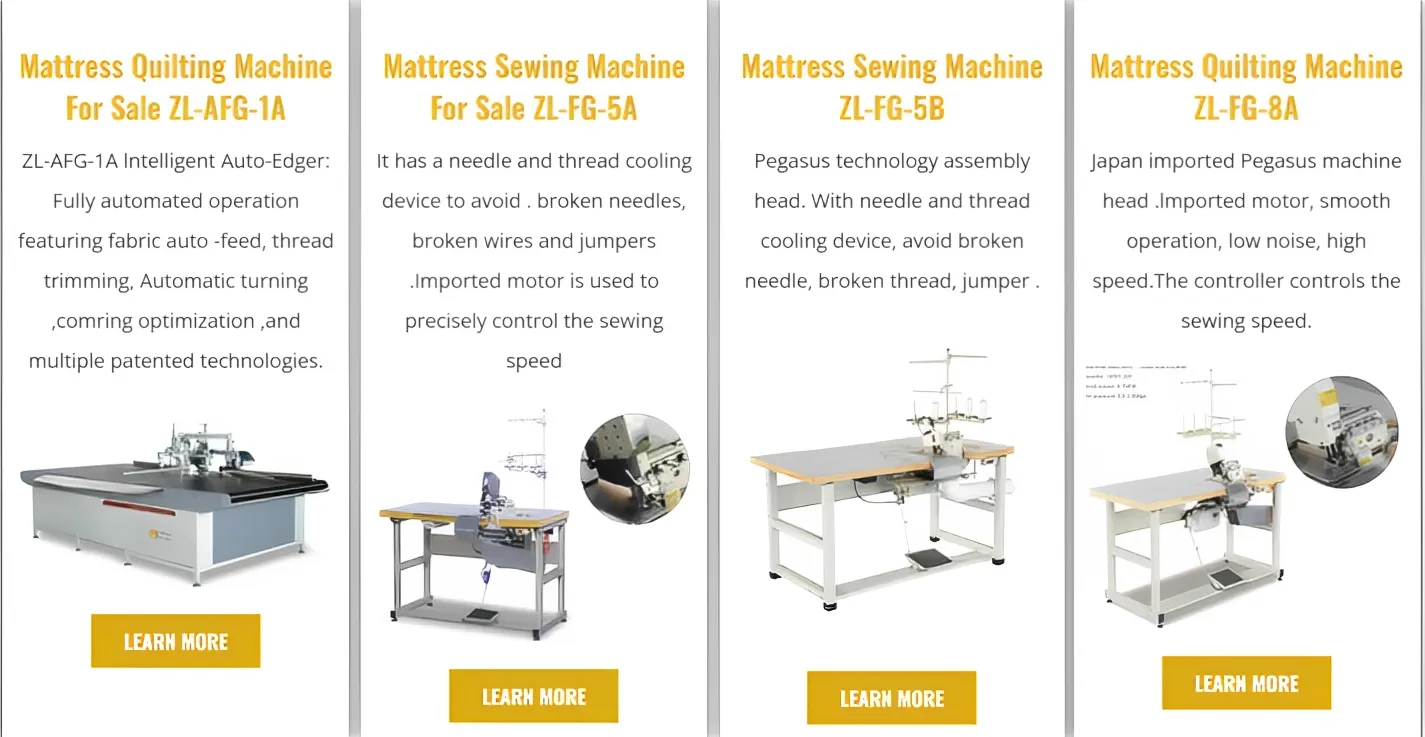

Flange Series

Mattress Quilting Machine For Sale ZL-AFG-1A

ZL-AFG-1A lntelligent Auto-Edger: Fully automated operation featuring fabric auto -feed, thread trimming, Automatic turning ,comring optimization ,and multiple patented technologies.

- Sewing thickness:≤ 80 mm

- Maximum speed:3000 RPM

- Stitch length:30 mm

Mattress Sewing Machine For Sale ZL-FG-5A

It has a needle and thread cooling device to avoid . broken needles, broken wires and jumpers .Imported motor is used to precisely control the sewing speed

- Seam Thickness :20-70 mm

- Seam Pitch:2-5 mm

- Seam Width:18 cm, 20 cm, 25 cm, 30 cm, 35 cm

Mattress Sewing Machine ZL-FG-5B

Pegasus technology assembly head. With needle and thread cooling device, avoid broken needle, broken thread, jumper .

- Speed :2,800–3,500 stitches/min

- Max Mattress Thickness:Up to 450 mm

- Supported Mattress TypesSpring, latex, memory foam, hybrid

Mattress Quilting Machine ZL-FG-8A

Japan imported Pegasus machine head .lmported motor, smooth operation, low noise, high speed.The controller controls the sewing speed.

- Power Supply :380V / 50Hz

- Max Sewing Thickness:80 mm

- Working Table Width 2000 mm

Advanced Production Equipment

ZL is a leading manufacturer of mattress machinery with 15+ years of experience. Our 20,000+ m² factory and 80+ R&D experts enable us to deliver customized, efficient solutions to 2000+ global clients in 150+ countries.

The Ultimate Guide to Buying Mattress Machine

Purchasing the right mattress machinery is crucial for efficient production, high product quality, and sustainable growth.

This detailed guide will help you make an informed decision.

Production Needs

1. Understand Your Production Needs

Before investing, clearly define your production goals:

- Mattress Type and Structure: Are you producing Bonnell springs, pocket springs, LFK springs, foam mattresses, hybrid models, or specialty mattresses? Different mattress types require different machinery.

- Production Capacity: Determine your daily or monthly output targets. Are you focusing on small-batch, multi-variety production or large-scale standardized manufacturing? This affects the number and automation level of machines needed.

- Automation Level: Decide if you prefer semi-automatic lines for flexibility or fully automated lines for maximum efficiency and labor cost reduction.

- Customization Requirements: Consider if your mattresses have unique sizes, shapes, or designs that require customized machinery or accessories.

- Budget: Establish your investment budget to balance cost and performance effectively.

Key Machinery Categories

2. Key Machinery Categories and Functions

Mattress production involves multiple steps such as spring making, core assembly, fabric sewing, border processing, inspection, and packaging. Consider these essential machines:

A. Spring Machinery

- Spring Coiling Machines: For producing various spring types like Bonnell, pocket springs (including high‑compression models), and LFK springs.

- Spring Assembly Machines: To connect individual springs into units, including fully and semi‑automatic assembly and gluing machines.

- Auxiliary Equipment: Spring conveyors, straighteners, and quality inspection systems. Focus on production speed, compatible spring types, and automation level.

B. Core Material Processing Equipment

- Foam Cutting and Shaping: High‑precision CNC or vertical foam cutters for accurate foam layer dimensions.

- Gluing Systems: Hot melt or water‑based adhesive systems to bond mattress layers efficiently and cost‑effectively.

C. Border and Sewing Machines

- Automatic Tape Edge Machines: For fast, precise edge banding.

- Semi‑Automatic Tape Edge Machines: Suitable for lower‑speed or more manual processes.

- Border Processing: Marking, cutting, stitching, and decorating machines for mattress edges.

- Label and Handle Sewing Machines: For final product finishing.

- Long Arm and Flat Sewing Machines: High‑speed single‑needle and flatbed machines for versatile sewing needs.

- Special Systems: Automatic tape and zipper systems for advanced mattress features.

D. Filling and Quilting Machines

- Filling Equipment: Evenly distributes filling materials inside mattresses.

- Quilting Machines: Stitch mattress cover layers with decorative patterns for durability and aesthetics.

E. Compression and Packaging Equipment

- Mattress Compressors: Reduce mattress volume for easier transport and storage, essential for e‑commerce.

- Packaging Machines: Vacuum sealing and wrapping machines to protect mattresses during shipment.

- Auxiliary Packaging Equipment: Labeling and stacking machines to streamline logistics.

Quality & Support

3. Quality, Certification, and After-Sales Support

- Manufacturer Credentials: Choose ISO 9001 or equivalent certified manufacturers to ensure quality management.

- Product Quality and Durability: Verify materials, craftsmanship, and key component suppliers for long-lasting equipment.

- Global Compliance: Ensure machinery meets safety, environmental, and performance standards relevant to your target markets.

- After-Sales Service: Confirm availability of installation, training, spare parts supply, and 24/7 technical support.

- Customization (ODM/OEM): Opt for manufacturers offering tailored solutions to fit your unique production requirements.

Cost Efficiency

4. Budget, ROI, and Cost Efficiency

- Price Considerations: Machinery prices vary based on brand, automation, and features. Set a realistic budget.

- Return on Investment: Evaluate long-term benefits such as increased productivity, reduced labor, and improved product quality rather than just upfront cost.

- Operating Costs: Consider energy consumption, maintenance, spare parts, and labor expenses. Energy-efficient machines reduce ongoing costs.

Innovation

5. Sustainability and Technological Innovation

- Green Manufacturing: Prioritize energy-saving, low-loss machinery to reduce environmental impact and operational costs.

- Smart Automation: Modern machines with sensors, data analytics, and remote control capabilities enable better production monitoring, predictive maintenance, and quality control.

Final Tips

6. Purchasing Process and Final Tips

- Market Research: Gather information on manufacturers, technologies, and reputation.

- Factory Visits: Inspect production facilities and see machines in operation if possible.

- Product Demonstrations: Request demos or trial runs to verify performance.

- Contract Details: Clearly define machine specifications, delivery, installation, warranty, and payment terms in contracts.

- Customer Feedback: Consult existing users for real-world experience with the equipment and service.