Cost Control in Mattress Production: Strategies for Success?

Margins are tight, competition is fierce—every dollar saved in production gives you a pricing edge and more profit.

To control costs in mattress manufacturing, we must optimize raw materials, labor, production, and energy—while still meeting quality and delivery standards.

In this guide, I’ll walk you through the same cost-saving strategies we use across Southeast Asia and Europe to help mattress factories run lean and stay profitable.

How can raw material sourcing reduce mattress production costs?

Raw material is your biggest cost—waste it, and your margin vanishes.

Build long-term partnerships with reliable suppliers, use bulk ordering, and adopt just-in-time inventory systems to reduce material costs and minimize waste.

We help clients lock in foam and fabric pricing for 6–12 months to hedge against fluctuations. For spring units, we suggest standardizing sizes across SKUs to increase buying power. Our machines are designed to work with multiple fabric widths, so clients can source from different suppliers if needed.

Key Tips for Material Cost Control

| Strategy | Impact |

|---|---|

| Bulk ordering | Reduces unit price by 10–20% |

| Local sourcing | Lowers transport cost, avoids delays |

| Standard component specs | Easier to manage inventory |

| Real-time stock tracking | Avoids over/understocking |

What are the best ways to optimize mattress production lines?

Manual processes eat up time and invite inconsistency.

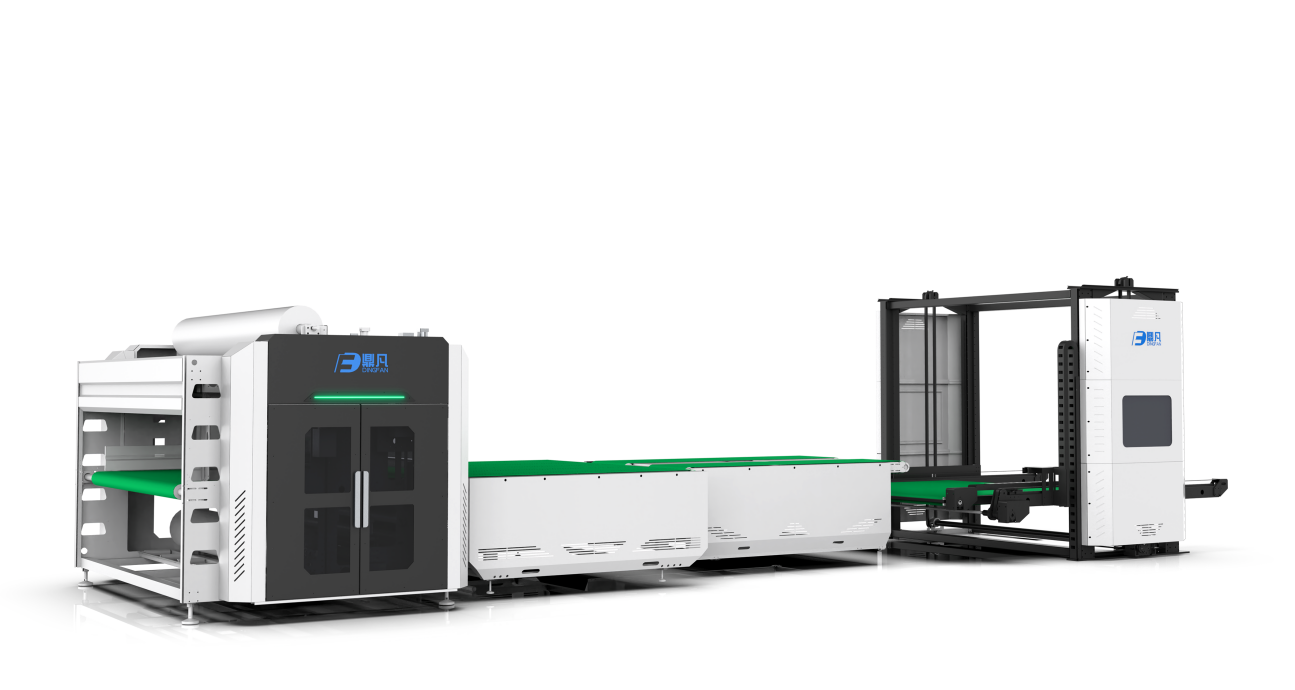

Use automation, layout redesign, and bottleneck analysis to improve production flow and reduce labor hours per unit.

One client in Vietnam reduced their spring bagging cost per piece by 30% by upgrading to a double-head pocket spring machine. Another optimized mattress gluing lines by replacing rollers with servo-controlled guns, cutting glue use by 15%.

How to manage labor costs without cutting corners?

Labor is essential—but overstaffing or under-training burns money fast.

Train operators thoroughly, monitor shift productivity, and link bonuses to KPIs like output per hour or defect rates.

We support mattress plants with video-based SOPs and on-site training for line leaders. When operators understand machine rhythm and maintenance, they make fewer errors and boost output without increasing headcount.

Labor Optimization Tactics

- Cross-train staff for multiple machines

- Introduce time clocks and shift KPIs

- Use incentives tied to quality and speed

- Rotate to avoid burnout and errors

How do quality control systems help cut hidden costs?

Returns, rework, and warranty claims quietly kill profit.

Invest in inline quality checks and staff training to catch problems early, not after delivery.

We install real-time sensors on glue lines to check nozzle pressure, preventing under-gluing. Some customers use weight sensors to confirm spring count. All this reduces rework by up to 40% and increases first-pass yield.

Can better energy use reduce production costs?

High electricity bills? Old machines and lights are often the culprits.

Conduct energy audits, upgrade to LED and inverter motors, and shut down idle machines during breaks to save costs.

In one Malaysian factory, switching to servo-based motors on their compression machines saved 20% energy per shift. We also helped them rewire their layout for better power phase balance.

Energy Saving Recommendations

| Area | Upgrade |

|---|---|

| Lighting | Switch to LED, use motion sensors |

| Motors | Use inverters (VFD) on all high-power units |

| Air compressor | Replace leaks, set pressure limits |

| Schedule | Run heavy equipment during off-peak hours |

How to optimize supply chain and logistics?

Fast delivery saves orders, but rushed shipping kills margins.

Plan procurement windows, build buffer stock on slow items, and group deliveries by route or region.

We recommend using ERP tools to visualize inbound/outbound logistics. For exports, container optimization software helps fit more mattresses per load, reducing shipping cost per unit.

Can product design help save costs?

Too many layers? Rare components? Fancy trims? That’s cost stacking up.

Design for manufacturability—use fewer SKUs, shared cores, and modular layers that simplify assembly.

One client cut foam SKU count from 11 to 5 by redesigning mattress layers to reuse standard base and transition foam. This alone saved over $12,000/month in material costs and simplified procurement.

How should mattress brands approach pricing?

Price too low—you lose money. Too high—you lose orders.

Use cost-plus pricing with built-in margins for each channel, and offer tiered products to cover different buyer groups.

For B2B clients, we suggest separate pricing for full container orders vs. sample orders. Add-ons like branded fabric or packaging can be upcharged as options.

What waste reduction methods really work?

Scrap foam, fabric rolls, excess glue—waste adds up.

Measure waste by type and source, then invest in foam shredders, glue dispensers, and CNC cutters to reduce it.

We helped a client in the Philippines recover 80% of their foam offcuts into shredded pillow filler, creating a new product and reducing disposal cost.

How to build a culture of continuous improvement?

One-time cost savings are good—but ongoing improvement builds long-term advantage.

Set up weekly improvement meetings, track cost metrics, and reward staff suggestions that save money.

We provide our clients with lean templates to run Gemba walks and Kaizen blitzes. Small daily changes—like relabeling parts bins or reorganizing a glue station—often save thousands over time.

Conclusion

Controlling costs is not just about cutting—it’s about smart planning, better training, and machines that work harder for less. With the right systems in place, your mattress factory can win in both price and performance.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com