Tape Edge Process Standardization: How Equipment Improves Mattress Consistency

In modern mattress manufacturing, product consistency has become as important as comfort and durability. Large retailers, brand owners, and export markets increasingly demand that every mattress leaving the factory looks and performs the same, regardless of production date, shift, or operator. Among all processes, tape edging is one of the most critical—and most challenging—steps to standardize.

Uneven edges, inconsistent stitch density, distorted corners, or visible waviness immediately signal instability in production. Even when internal materials are identical, inconsistent tape edging can make mattresses appear uneven or low quality. For this reason, tape edge process standardization is no longer optional. It is a core requirement for factories aiming at stable output and scalable growth.

This article explains how professional equipment enables tape edge process standardization and, as a result, significantly improves mattress consistency. The focus is not on operator technique, but on how machine structure, control logic, and automation transform tape edging from an experience-driven task into a repeatable industrial process.

For reference to related equipment and integrated production concepts, you may consult the internal company page:

https://mattressmachineryzl.com/

Why Tape Edge Consistency Is So Difficult to Achieve

Tape edging combines sewing, feeding, mattress handling, rotation, and corner transitions into a single continuous operation. Unlike flat sewing, the mattress edge is soft, compressible, and constantly changing shape during movement.

Several factors make consistency difficult:

(1) Mattress thickness varies between models and even within one mattress

(2) Material compressibility changes under pressure

(3) Direction and speed must change at corners

(4) Human reaction time differs from operator to operator

In traditional setups, operators compensate for these variables manually. This makes quality highly dependent on individual skill, attention, and physical condition. As production volume increases, such dependence becomes a major risk.

Standardization requires removing this variability at its source.

What Tape Edge Standardization Really Means

Tape edge standardization does not mean producing a “perfect” edge once. It means producing the same edge every time.

In practical terms, standardization means:

(1) Stitch spacing remains consistent across all mattresses

(2) Edge distance is uniform along straight lines and corners

(3) Corner shape and curvature are repeatable

(4) Visual appearance does not change between shifts or operators

Achieving this level of consistency is not realistic with manual or semi-manual control alone. It requires equipment that embeds quality into the process itself.

hw-remosaic: 0;

touch: (-1.0, -1.0);

modeInfo: ;

sceneMode: LLHDR;

cct_value: 0;

AI_Scene: (-1, -1);

aec_lux: 266.51056;

hist255: 0.0;

hist252~255: 0.0;

hist0~15: 0.0;

The Role of Equipment in Eliminating Human Variability

The most significant contribution of modern tape edge equipment is the reduction of human influence on critical process variables.

In standardized systems:

(1) Sewing speed is controlled by the machine

(2) Feeding speed is synchronized automatically

(3) Pressure is applied consistently

(4) Corner transitions follow predefined logic

Operators no longer decide how fast to sew, when to slow down, or how to handle corners. Instead, they monitor the process and intervene only when necessary.

This shift from manual execution to system execution is the foundation of consistency.

Machine Structure as the Basis of Repeatability

Standardization begins with mechanical structure. If the machine itself is unstable, no amount of control logic can ensure consistent results.

Professional tape edge equipment is designed with:

(1) Rigid sewing head mounting to prevent vibration

(2) Stable frames that resist deformation under load

(3) Precision-guided movement paths

These structural features ensure that stitch formation and edge tracking remain stable over long production cycles. Without this mechanical foundation, consistency degrades over time.

Synchronized Feeding Systems and Uniform Tension

Feeding behavior directly affects tape edge appearance. Inconsistent feeding causes uneven tension, leading to ripples, loose tape, or stretched stitches.

Standardized equipment uses synchronized feeding systems that:

(1) Match feeding speed precisely to sewing speed

(2) Maintain constant contact pressure

(3) Adjust smoothly during acceleration and deceleration

This synchronization ensures that materials move as a single system, allowing stitches to settle flat and uniformly along the edge.

Adaptive Pressure Control for Material Variation

Mattresses vary widely in construction. Foam density, quilting thickness, and edge reinforcement all affect how the material responds to pressure.

Manual systems cannot adapt quickly or consistently to these variations. Standardized equipment solves this by using adaptive pressure mechanisms that:

(1) Automatically compensate for thickness changes

(2) Prevent over-compression in thick areas

(3) Avoid slippage in thin areas

By stabilizing pressure, the equipment ensures consistent edge geometry across different mattress models.

Corner Handling as a Key Standardization Challenge

Corners are the most common source of inconsistency. Even small differences in handling speed or angle produce visible defects.

Standardized tape edge equipment uses programmed corner control to:

(1) Reduce sewing speed smoothly at corners

(2) Adjust feeding pressure dynamically

(3) Control sewing head movement and angle

This ensures that every corner follows the same path, producing identical curvature and stitch density across all mattresses.

Centralized Control Logic and Recipe Management

A major advantage of modern tape edge equipment is centralized control.

Through control systems, manufacturers can define and store:

(1) Sewing speed

(2) Stitch length

(3) Feeding pressure

(4) Corner behavior

These settings can be saved as recipes for different mattress models. When production switches, operators simply select the correct program. The system automatically applies all parameters, eliminating manual readjustment and reducing setup errors.

This capability is critical for factories producing multiple models or custom orders.

Reduced Training Time and Workforce Stability

Standardization also affects workforce management.

When quality depends on operator skill, training takes longer and turnover causes instability. With standardized equipment:

(1) Operators require less specialized sewing skill

(2) Training focuses on operation and monitoring

(3) Quality remains stable even with new staff

This improves workforce flexibility and reduces the risk associated with losing experienced workers.

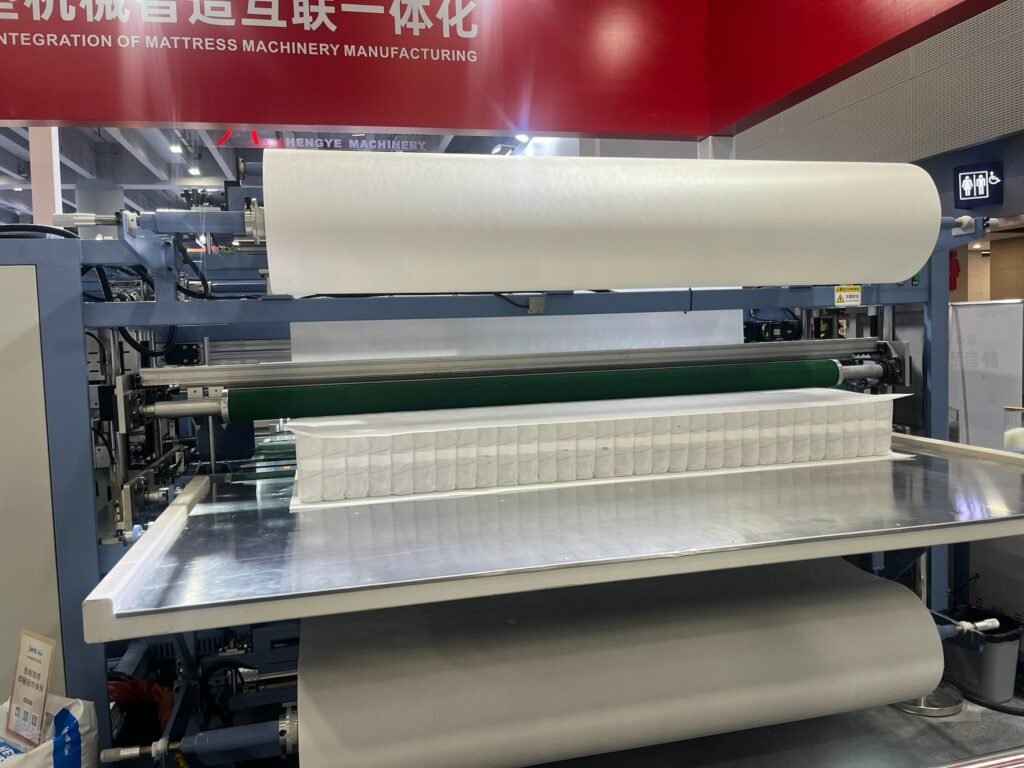

Integration with Automated Production Lines

Tape edge standardization is most effective when equipment is integrated into a broader automated system.

Modern tape edge machines are designed to connect with:

(1) Automatic feeding systems

(2) Mattress flipping and rotation units

(3) Conveyors and stacking equipment

This integration ensures consistent orientation, timing, and handling throughout the production flow. It further reduces manual intervention and reinforces overall consistency.

More information about integrated production solutions can be found internally at:

https://mattressmachineryzl.com/

Long-Term Consistency and Quality Control

One often overlooked benefit of standardized equipment is long-term stability.

Because movements are controlled and mechanical stress is reduced:

(1) Wear progresses more slowly

(2) Calibration remains stable

(3) Quality does not drift gradually over time

This reduces the need for frequent adjustment and minimizes hidden quality loss that might otherwise go unnoticed until customer complaints arise.

Summary Table: How Equipment Standardization Improves Mattress Consistency

Process Aspect | Non-Standardized Setup | Standardized Equipment

Sewing speed control | Operator-dependent | Machine-controlled

Feeding behavior | Manual adjustment | Fully synchronized

Pressure application | Inconsistent | Adaptive and stable

Corner handling | Experience-based | Programmed and repeatable

Training requirement | Long | Short

Batch-to-batch consistency | Variable | Highly consistent

Why Standardization Becomes Critical at Scale

Small factories may tolerate some variation. High-volume factories cannot.

As output increases:

(1) Small inconsistencies multiply

(2) Rework costs rise

(3) Brand risk increases

Standardization through equipment is the only practical way to maintain consistency at scale. It ensures that quality is built into the process rather than inspected at the end.

Conclusion: Equipment Is the Foundation of Tape Edge Standardization

Tape edge process standardization is not achieved through stricter supervision or more training. It is achieved by designing variability out of the process.

Professional tape edge equipment provides the structure, control, and automation needed to produce consistent results regardless of operator, shift, or production volume. By stabilizing sewing, feeding, pressure, and corner handling, equipment transforms tape edging into a predictable and repeatable operation.

For mattress manufacturers aiming to improve consistency, reduce rework, and protect brand value, investing in standardized tape edge equipment is not simply a technical upgrade. It is a strategic decision that directly shapes long-term competitiveness.