GDZ9C 系列 སྤུགས་སྐད་སྤྲོད་ལེན་ལག་འཁོར་ལས་ཁུངས། ལོ་གསར་ མཚམས་ལས་སྤུགས་སྐད་སྤྲོད་ལེན་ལག་འཁོར་ལས་ཁུངས།

When I look back on the evolution of mattress manufacturing over the past decade, I consistently see one foundational element shaping both productivity and product quality: the pocket spring. Factories that once relied on slower and less stable machinery are now in a race to modernize, driven by rising global demand and increasing expectations for comfort, support, and product consistency. Among the various innovations I have encountered, the GDZ9C Series Pocket Spring Machine stands out as one of the most impactful upgrades a factory can make.

From the first moment I observed a GDZ9C machine running at full speed, the difference was obvious. The movement was cleaner. The production rhythm was more predictable. Material waste was nearly invisible. It was clear to me that the GDZ9C Series was designed not only to make springs faster, but to transform the entire production chain surrounding the spring unit. In many of the factories I have worked with, introducing the GDZ9C system has unlocked new levels of operational reliability, material savings, and general scalability.

The GDZ9C Series is more than a single machine model. It represents a category of high-speed, low-loss manufacturing equipment with strong adaptability. Whether producing cylindrical or barrel-shaped springs, single-wire or dual-wire configurations, standard or zoned mattress structures, the GDZ9C Series delivers stable output even under high-volume conditions.

Why Pocket Spring Manufacturing Defines Mattress Quality

Pocket spring technology has become the dominant choice for mid- to high-end mattresses. The ability to isolate pressure, provide uniform body support, and reduce motion transfer has made it the preferred structural component for comfort-focused sleep brands. Yet, the quality of a mattress is directly tied to the precision and consistency of its springs.

A poorly welded pocket, an inconsistent spring height, or misaligned fabric can compromise the entire mattress. That is why, in every project I’ve participated in, the first recommendation I make to factories seeking higher quality is to upgrade their spring production line. The GDZ9C Series plays a central role in this transformation.

The machine was engineered to meet three critical production demands:

- High throughput

- Low material waste

- Long-term operational stability

As sleep product innovation continues to rise, factories must rely on equipment that protects both productivity and product quality. The GDZ9C Series was built precisely for this purpose.

Core Features That Define the GDZ9C Series

During my evaluations of this machine line, I consistently identify several features that make the GDZ9C one of the most effective pocket spring systems in today’s market.

(1)High-Speed Coiling with CNC Precision

The GDZ9C Series includes a fully CNC-controlled coiling head capable of reaching speeds of 180 springs per minute in stable operation. This speed is not merely a performance figure—it is a reflection of the machine’s overall synchronization across wire feeding, cutting, heat treatment, and forming. Through digital control, each parameter can be set with high accuracy:

- स्प्रिङको उचाइ

- Spring diameter

- Wire diameter

- Coiling pitch

- Tension patterns

Factories benefit because every spring maintains consistent geometry. This directly improves downstream processes such as gluing, assembly, and mattress unit formation.

(2)Advanced Heat Treatment System

One of the common weaknesses of older spring machines is poor heat treatment, which affects elasticity and long-term spring resilience. The GDZ9C Series incorporates an intelligent heat-treatment mechanism that preconditions the steel wire before coiling.

This contributes to:

- Better rebound

- Longer spring life

- Fewer defects in spring shape

In some factories I visited, inconsistent heat treatment once caused sagging or harsh rebound in finished mattresses. After installing GDZ9C systems, these issues were drastically reduced.

(3)Low-Waste Non-Woven Feeding and Ultrasonic Welding

Material waste is one of the most important cost factors in pocket spring production. The GDZ9C Series is designed with:

- Automatic non-woven feeding and splicing

- Stable ultrasonic welding

- Optimized fabric tension control

- Accurate cut-off systems

These features work together to eliminate loose bags, misaligned seams, and inconsistent pocket lengths. The outcome is smoother downstream assembly and reduced rework.

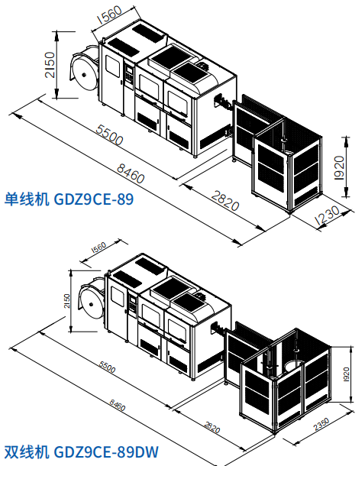

(4)Single-Wire and Dual-Wire Flexibility

Factories often struggle with switching between different mattress designs. The GDZ9C Series offers strong adaptability:

- GDZ9C-180 uses single-wire coiling

- GDZ9C-180DW uses dual-wire coiling for zoned mattresses

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

| ནུས་རྩལ་ཚད་གཞི། | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | 1%–2% | cURL Too many subrequests. |

| پەیوەندی بەرزایەتی هەڵکەوتن | ལོངས་མཐོ་ནས་ལོངས་མཐོ་ནས། | ཕུལ་བྱུང་། | cURL Too many subrequests. |

| دقیقەی جوشکاری | འབྲིང་ཙམ། | མཐོ་བ། | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | کەم | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | Minimal stoppage time |

| Energy Efficiency | ཚད་ལྡན། | Optimized | Lower operational cost |

| Zoning Capability | ཚད་བཀག | Full dual-wire support | Enables premium mattress production |

Dive Deeper: How the GDZ9C Series Impacts Long-Term Cost Efficiency

To fully understand the value of the GDZ9C Series, it is necessary to look beyond raw production numbers and examine the long-term financial implications. Many factory managers underestimate how much operational inefficiency costs them each year.

The GDZ9C Series helps reduce indirect costs in several ways:

- Lower labor requirements due to automated feeding

- Reduced rework caused by inconsistent spring dimensions

- Less downtime, contributing to more predictable deadlines

- Longer machine lifespan due to precise load control

- Lower energy consumption compared to legacy systems

Additionally, improved spring consistency reduces customer complaints, returns, and warranty claims—factors that significantly influence brand reputation.

Dive Deeper: Operational Stability and Factory Workflow Optimization

In my experience, the GDZ9C Series often becomes the anchor of a mattress factory’s entire production line. When spring production is stable, the rest of the workflow becomes easier to manage. Glue application becomes more uniform. Assembly lines run without interruption. Storage and logistics teams face fewer delays.

The GDZ9C Series enhances operational flow in these ways:

- Better alignment of production schedules

- More predictable batch output

- Reduced bottlenecks between stages

- Improved coordination between departments

For factories aiming to scale production or pursue export markets, these advantages can be transformative. A highly stable spring production system is the foundation upon which international competitiveness is built.

Conclusion: Why the GDZ9C Series Is a Strategic Investment for Mattress Manufacturers

After observing the GDZ9C Series across multiple production environments, I am convinced it stands among the most valuable upgrades available to mattress factories today. Its combination of efficiency, stability, low waste, and product flexibility makes it an essential tool for modern manufacturing.

Factories that adopt the GDZ9C Series typically experience:

- Higher throughput

- Lower cost per unit

- Improved mattress quality

- Stronger competitive positioning

- Reduced operational risk

- Greater adaptability to market trends

In a global industry that is increasingly competitive, the GDZ9C Series helps factories stay ahead by delivering consistent, high-quality pocket springs while minimizing costs and maximizing uptime. It is not just an equipment purchase—it is a long-term strategic investment in productivity and brand credibility.