Can One Machine Produce Different Types of Mattress Springs?

Can One Machine Produce Different Types of Mattress Springs?

Introduction

The mattress industry is ever-evolving, driven by consumer demand for comfort, durability, and customization. At the heart of many mattresses are the springs, which provide support and resilience. There are various types of mattress springs, such as Bonnell springs, pocket springs, continuous coils, and offset coils, each offering unique benefits. Traditionally, producing these diverse springs required specialized machinery for each type, but recent technological advancements have made it possible for a single machine to efficiently produce multiple types of mattress springs. In this article, we’ll explore how modern innovations in spring manufacturing technology enable machines to produce different types of springs, the benefits of this approach, and the future of the industry.

Introduction to Mattress Springs

Mattress springs are integral components that influence the overall comfort and support of a mattress. The most common types of springs used in the industry include:

- Bonnell Springs: Known for their hourglass shape, these springs provide firm support and are commonly used in innerspring mattresses.

- Pocket Springs: Individually wrapped in fabric pockets, pocket springs offer targeted support and reduce motion transfer, making them ideal for couples.

- Continuous Coils: Made from a single piece of wire, continuous coils offer durability and provide a consistent feel across the mattress.

- Offset Coils: With their squared-off edges, offset coils provide better contouring and support.

The variety in spring types allows manufacturers to cater to diverse consumer needs, making it essential for production systems to be versatile. The ability to efficiently produce multiple spring types with one machine could revolutionize the way mattresses are manufactured.

Technological Advancements in Spring Manufacturing

The mattress manufacturing industry has seen significant technological advancements in recent years, especially in the production of mattress springs. Modern machinery is now designed with the flexibility to produce various types of springs with precision and efficiency.

Innovations such as computer-controlled winding machines, automated assembly lines, and advanced software controls have transformed spring manufacturing. These technologies enable machines to produce springs with consistent quality, reducing defects and increasing productivity. Additionally, advancements in materials science have led to stronger, more durable spring materials, further enhancing the overall quality and longevity of the final mattress product.

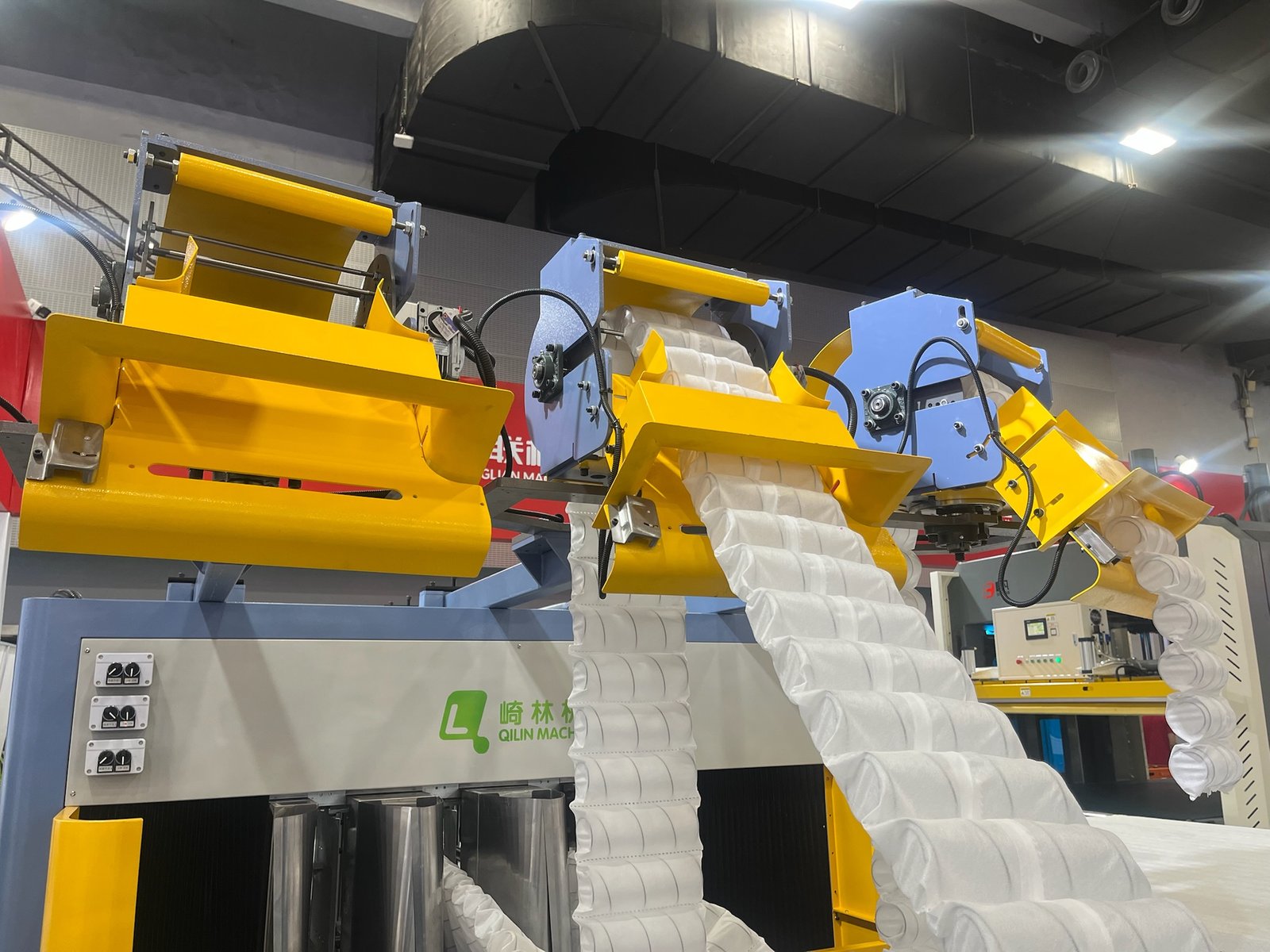

Multi-Functionality of Modern Machines

Modern mattress spring machines are highly versatile and can seamlessly switch between producing different types of springs. This flexibility is made possible through several key features:

- Adjustable Settings: Machines can modify parameters such as coil diameter, wire gauge, and tension to accommodate different spring types.

- Interchangeable Parts: Machines use modular components, such as different forming tools and mandrels, which allow for easy customization between different spring types.

- Advanced Software Controls: Operators can use sophisticated software to program and monitor the production process, ensuring precision across different spring types.

This multi-functionality not only simplifies production but also reduces the need for specialized machines, leading to cost savings and increased operational efficiency. Manufacturers can now respond to market demand faster and more flexibly, producing a wide variety of mattress springs with minimal downtime.

Customization and Flexibility

A significant advantage of modern spring manufacturing machines is their ability to be customized to meet specific production needs. These machines can be fine-tuned to produce springs with varying gauges, coil counts, and tension levels, depending on the desired mattress design.

For example:

- A machine may produce firmer springs for orthopedic mattresses and softer springs for luxury or plush mattresses.

- Machines can quickly adjust to produce pocket springs with different coil diameters or continuous coils with varying tension levels.

This level of customization allows manufacturers to meet the varying preferences of consumers while also adapting to emerging market trends. The ability to quickly switch between different types of springs makes these machines highly adaptable to changing demands.

Production Efficiency and Cost-Effectiveness

Using a single machine to produce different types of springs offers several benefits, including improved production efficiency and cost-effectiveness. One of the key advantages is reduced downtime. Manufacturers can switch between different spring types without the need for lengthy reconfiguration or setup, leading to higher productivity and faster turnaround times.

Moreover, the versatility of these machines reduces the need for multiple specialized machines, resulting in lower capital investment and maintenance costs. Labor costs are also minimized, as fewer operators are needed to manage the production process.

This combination of higher output, lower costs, and faster production enhances the overall efficiency of mattress manufacturers, making high-quality mattresses more affordable for consumers.

Quality Control and Consistency

Quality control is a critical aspect of mattress spring production, especially when using a single machine to produce different types of springs. Modern machines come equipped with automated quality control systems that monitor various parameters during production, such as coil diameter, wire tension, and spring height.

These systems detect any deviations from the desired specifications and make immediate adjustments to maintain consistent quality. Advanced software analytics provide detailed reports on production performance, allowing manufacturers to identify and resolve any issues promptly.

Maintaining consistency ensures that every spring, regardless of its type, meets the required standards. This precision in quality control not only enhances consumer satisfaction but also builds the reputation of manufacturers in a competitive market.

Case Studies and Industry Examples

Several manufacturers have successfully implemented versatile spring manufacturing machines, showcasing the practical benefits of producing multiple types of springs with a single machine. For instance, a leading mattress manufacturer faced challenges in meeting the growing demand for pocket springs while also needing to produce Bonnell springs for their budget lines. By adopting a multi-functional machine, they were able to streamline their production process, reduce equipment costs, and meet both high-end and budget demands without sacrificing quality or efficiency.

Such case studies highlight the significant advantages of these machines in real-world production environments. These companies have been able to adapt quickly to changing market demands, increase their production capacity, and maintain competitive pricing.

Conclusion

The mattress manufacturing industry has evolved, and modern spring manufacturing machines have kept pace by offering the ability to produce different types of springs efficiently with one machine. This technological advancement has brought substantial cost savings, increased flexibility, and improved production efficiency. By adopting multi-functional machines, manufacturers can cater to a wider range of consumer preferences, produce high-quality springs, and remain agile in a rapidly changing market. With further advancements on the horizon, we can expect the industry to continue its shift toward more versatile, cost-effective, and technologically advanced production systems.