Une analyse technique des machines à ressorts à poche multifonctions capables de produire des ressorts en forme de Z et en forme de baril

When I first began evaluating pocket spring lines across different mattress factories, I noticed that product diversity had become a key competitive factor in the global bedding market. Manufacturers were no longer satisfied with producing only standard cylindrical springs. Instead, they required machines capable of producing specialized spring geometries—such as Z-shaped and barrel-shaped coils—to meet evolving comfort requirements and design standards. These advanced structures allow mattress brands to differentiate their products with improved pressure distribution, enhanced support zones, and greater long-term durability.

The rise of multi-function pocket spring machines reflects this shift. These machines are engineered not simply to increase output speed, but to handle complex wire forming patterns with precision, stability, and efficiency. During my visits to factories that invested in such equipment, I consistently observed higher product flexibility, stronger market adaptability, and improved control over material use. This type of machinery enables factories to respond quickly to changing market preferences while maintaining consistent spring quality.

In this article, I will break down how multi-function pocket spring machines operate, why Z-shaped and barrel-shaped springs are important, and how modern engineering makes it possible to produce multiple spring types on the same equipment. I will also provide a detailed performance comparison table that reflects actual operational differences. For mattress factories considering diversification, this analysis will serve as a practical technical guide.

Why Spring Shape Matters in Modern Mattress Design

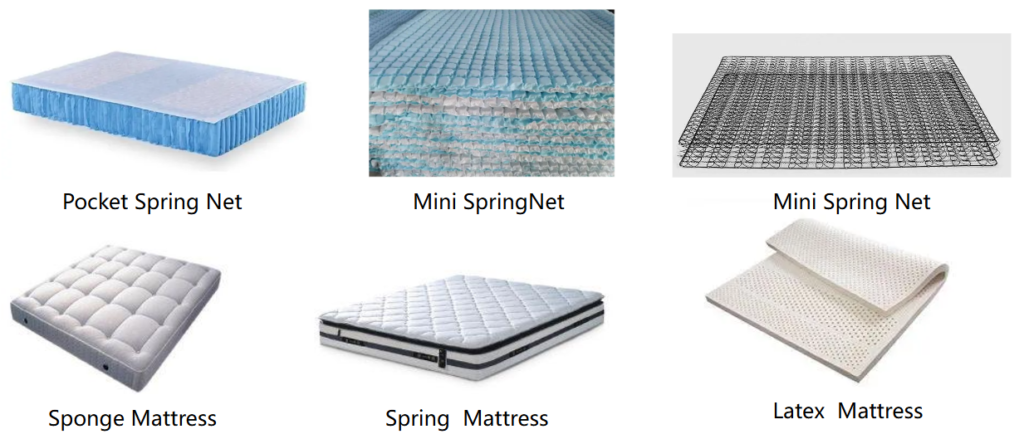

For years, cylindrical pocket springs dominated mattress manufacturing because they were simple to produce and provided predictable performance. However, as the market demanded better ergonomics, more tailored pressure distribution, and better durability, alternative spring geometries were introduced.

Z-shaped and barrel-shaped (also called drum-shaped) springs emerged as two widely adopted alternatives. Each shape carries unique structural advantages:

- Z-shaped springs provide progressive resistance and enhanced body contouring

- Barrel-shaped springs offer broader compression areas and smoother rebound curves

When I compare mattresses made with these spring types, I often feel the difference immediately. Z-shaped springs adjust quickly under localized pressure, while barrel-shaped springs distribute load more evenly across a wider surface area. These characteristics have made them popular in premium mattresses, hybrid systems, and zoned comfort layers.

This increased demand created the need for pocket spring machines capable of producing multiple spring shapes without extensive retooling.

Understanding Multi-Function Pocket Spring Machine Architecture

Multi-function pocket spring machines incorporate a range of engineering enhancements that allow them to switch between spring types efficiently. These machines rely heavily on servo-driven control systems, intelligent wire feeding mechanisms, and optimized coiling heads to achieve precision forming.

When I analyze multi-function machines in operation, several features consistently stand out:

(1)Adaptive CNC Coiling Head for Variable Spring Geometry

At the core of multi-function capability is the CNC coiling head. Unlike older mechanical systems, CNC heads use programmable profiles to shape wire into different spring geometries. For example:

- A Z-shaped spring requires specific pitch adjustments and angle shifts

- A barrel-shaped spring requires controlled diameter variation at the midsection

The CNC head allows operators to switch between spring types simply by selecting the desired profile on the control panel. This removes the need for hardware changes and allows rapid reconfiguration between product lines.

(2)Precision Wire Feeding and Real-Time Tension Control

Producing non-standard springs requires exceptionally stable wire tension. If tension fluctuates, Z-shaped coils lose structural accuracy and barrel-shaped coils lose shape symmetry. Multi-function machines use automatic tension sensors that regulate feeding speed and torque to ensure:

- Consistent pitch

- Stable coil height

- Accurate shape formation

This is one of the reasons why multi-function machines outperform older equipment in both speed and consistency.

(3)Enhanced Heat Treatment for Shape Retention

Both Z-shaped and barrel-shaped springs require reliable heat treatment to ensure the coil retains its geometry under pressure. Multi-function machines integrate:

- Pre-coil heating

- Controlled cooling

- Real-time temperature monitoring

These ensure the spring wire maintains elasticity and long-term fatigue resistance even after forming complex shapes.

(4)High-Strength Ultrasonic Welding to Withstand Shape Tension

Z-shaped and barrel-shaped springs place greater stress on pocket seams than cylindrical springs. As a result, multi-function machines include reinforced ultrasonic welding modules to:

- Strengthen the weld line

- Improve bonding consistency

- Reduce tearing during assembly

This upgrade ensures the durability of the entire spring unit.

(5)Flexible Non-Woven Fabric Control System

Because spring geometries vary, the fabric containment must adapt to different expansion patterns. Multi-function machines include:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

| Caractéristique | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|---|

| Spring Shapes Supported | Mostly cylindrical | Cylindrical, Z-shaped, barrel-shaped | Greater product flexibility |

| Changeover Speed | Slow or manual | Fast, software-controlled | Reduced downtime |

| Wire Feeding Precision | Moyen | High | Better spring uniformity |

| Ultrasonic Welding Strength | Standard | Reinforced | Better pocket durability |

| Fabric Control | Basic tension | Intelligent tension + auto-centering | cURL Too many subrequests. |

| Operator Skill Requirement | Moyen | Low to medium | Easier training |

| Production Consistency | cURL Too many subrequests. | High | Better mattress performance |

| Product Value Range | cURL Too many subrequests. | Mid-range to premium | Higher profit margins |

Dive Deeper: Engineering Challenges Behind Multi-Shape Production

It may seem simple for a machine to switch from one spring shape to another, but the underlying engineering challenges are substantial. Z-shaped springs demand precise angular transitions, while barrel-shaped springs require seamless diameter modulation. These complexities can easily introduce defects if the machine lacks:

- Real-time servo synchronization

- High-speed tension compensation

- Predictive control algorithms

- Consistent welding temperatures

- Structural rigidity to handle tension fluctuations

I have seen factories attempt to produce multi-shape springs on simpler machines, only to face high defect rates, irregular spring heights, and excessive waste. This reinforced my belief that multi-function capability must be engineered, not improvised.

Dive Deeper: Business Impact of Offering Multiple Spring Geometries

Factories that adopt multi-function machines often experience significant commercial advantages. By offering Z-shaped and barrel-shaped springs, they gain access to:

(1)Premium mattress segments

High-end brands seek advanced coil systems to differentiate from commodity products.

(2)Custom OEM opportunities

Private-label customers value flexibility in design.

(3)Better pricing power

Specialized springs command higher selling prices.

(4)Expanded global reach

Export markets value innovation and advanced support systems.

In many cases, factories switch from competing on cost to competing on innovation, a far more sustainable long-term strategy.

Conclusion: Multi-Function Pocket Spring Machines Represent the Future of Spring Production

After analyzing performance data, observing production lines, and discussing product engineering with mattress designers, I am confident that multi-function pocket spring machines represent a major advancement in mattress manufacturing. Their ability to produce cylindrical, Z-shaped, and barrel-shaped springs on one platform enables factories to expand their product portfolio, improve quality, and respond to market trends rapidly.

Factories that adopt multi-function systems typically see improvements in:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.