How Automatic Labeling Machines Help Mattress Manufacturers Enhance Brand Recognition

In today’s mattress market, brand recognition is no longer built only through advertising or showroom presentation. It is increasingly formed at the product level, through consistent visual identity, professional finishing, and repeatable details that customers encounter every time they see or touch a mattress.

Among these details, the brand label plays a unique role. It is often the only element on a mattress that directly communicates the brand name, logo, and positioning. When applied accurately and consistently, it reinforces trust and professionalism. When applied poorly, it weakens even the strongest brand message.

This is why more mattress manufacturers are paying attention to automatic labeling machines. These machines do far more than attach a label. They transform labeling from a manual afterthought into a standardized, controllable, and brand-building process.

This article explains how automatic labeling machines help mattress companies enhance brand recognition, focusing on process consistency, visual impact, production stability, and long-term brand value rather than simple labor savings.

For reference to related equipment and integrated production concepts, you may consult the internal company page:

https://mattressmachineryzl.com/

Why Brand Recognition Depends on Product-Level Consistency

Brand recognition is built through repetition. Customers recognize a brand because they repeatedly see the same visual elements presented in the same way.

In mattress products, this repetition depends on:

- Consistent label position

- Uniform label orientation

- Clean attachment without wrinkles or tilt

- Identical appearance across all models and batches

If labels are placed differently on each mattress, brand identity becomes fragmented. Customers may not consciously analyze this inconsistency, but they perceive it as a lack of professionalism.

Automatic labeling machines address this problem by removing variability from the labeling process.

The Limitations of Manual Labeling in Mattress Production

In many factories, labeling is still performed manually or semi-manually. Operators attach labels by hand after sewing or tape edging.

This approach has several inherent limitations:

- Position varies between operators

- Alignment depends on visual judgment

- Speed and pressure differ from person to person

- Fatigue leads to inconsistency over time

As production volume increases, these variations become more noticeable. Even small differences in label placement weaken the visual uniformity of the product line.

Manual labeling also struggles to keep pace with automated production lines, creating bottlenecks and quality risks.

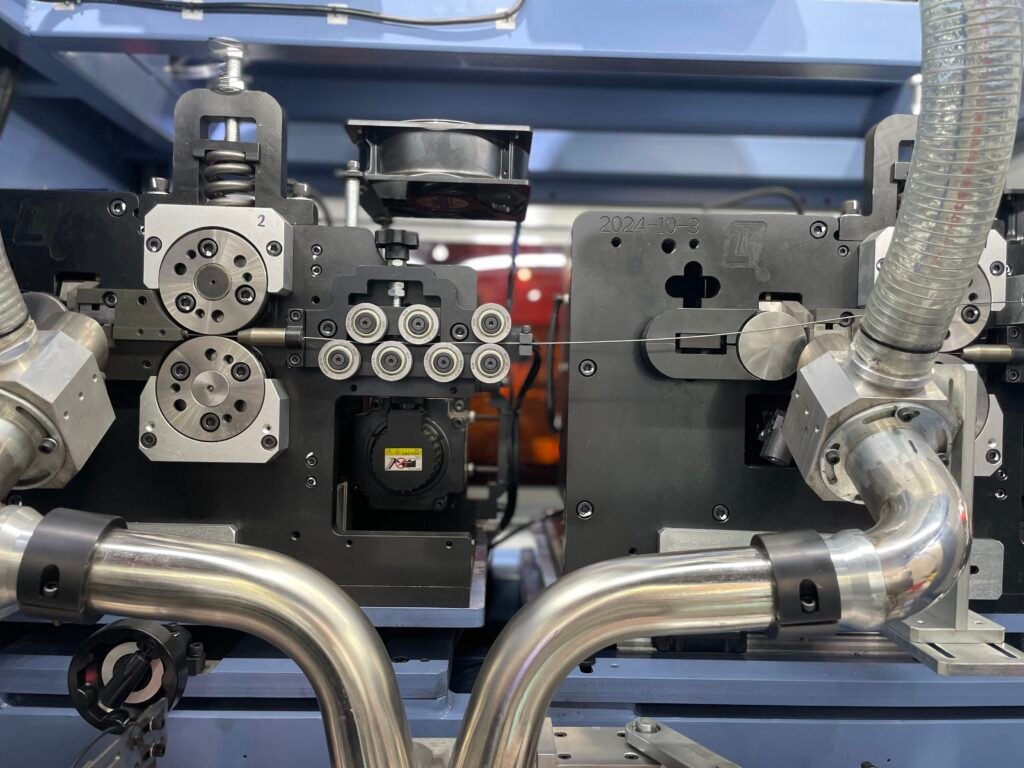

What Defines an Automatic Labeling Machine in Mattress Manufacturing

An automatic labeling machine is not simply a device that attaches labels faster. It is a system designed to standardize how and where branding elements appear on the product.

In mattress production, an automatic labeling machine typically:

- Positions labels at predefined locations

- Controls orientation and alignment

- Applies consistent pressure

- Synchronizes with production speed

These functions ensure that every mattress carries the brand in exactly the same way.

Consistent Label Placement as a Brand Signal

Consistency in label placement is one of the strongest visual signals of brand maturity.

Automatic labeling machines ensure that:

- Labels are always placed at the same height on the side border

- Distance from seams or corners remains constant

- Orientation is straight and repeatable

When customers see multiple mattresses from the same brand, this consistency reinforces recognition and trust. The brand feels deliberate and controlled rather than improvised.

Improved Visual Quality and Professional Appearance

Beyond position, visual quality matters.

Manual labeling often results in:

- Slightly tilted labels

- Wrinkles caused by uneven pressure

- Inconsistent attachment depth

Automatic labeling machines apply labels with controlled motion and pressure. This produces:

- Flat, smooth labels

- Clean edges

- Uniform appearance

These details contribute to a higher perceived product value, especially in mid- to high-end mattress segments.

Enabling Brand Standardization Across Multiple Product Lines

As mattress manufacturers expand, they often introduce multiple product lines under the same brand. Maintaining a consistent brand identity across different models becomes increasingly difficult.

Automatic labeling machines support brand standardization by:

- Using the same positioning rules for all models

- Allowing parameter adjustments for different sizes

- Ensuring visual consistency regardless of mattress dimensions

This allows brand identity to remain unified even as the product portfolio grows.

Supporting Premium Brand Positioning

For premium brands, details are part of the promise.

A precisely placed, well-finished label communicates:

- Attention to detail

- Manufacturing discipline

- Confidence in product quality

Automatic labeling machines help premium mattress brands deliver this message consistently. The label becomes an integrated part of the product design rather than an add-on applied at the end.

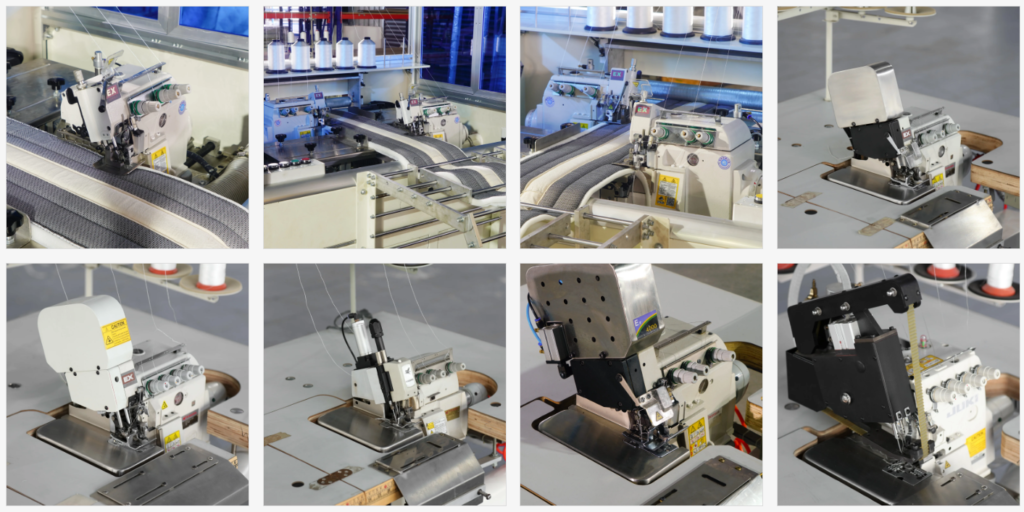

Integration with Automated Production Lines

Brand recognition is most effectively reinforced when labeling is integrated into the production flow.

Automatic labeling machines can be integrated with:

- Tape edge machines

- Side border sewing lines

- Conveying and handling systems

This integration ensures that labeling occurs at the correct moment, with consistent orientation and minimal manual handling. It also prevents damage or misplacement during downstream processes.

More information about integrated production solutions can be found internally at:

https://mattressmachineryzl.com/

Reducing Human Influence on Brand Presentation

One of the most important benefits of automatic labeling is the reduction of human influence on brand presentation.

When labeling depends on individuals:

- Visual results vary

- Training requirements increase

- Quality control becomes reactive

With automatic systems:

- Brand presentation is defined by parameters

- Results are repeatable across shifts

- Quality becomes predictable

This shift protects brand integrity as production scales.

Faster Training and Workforce Stability

Automatic labeling machines also simplify workforce requirements.

Operators no longer need to judge position or alignment manually. Training focuses on:

- Machine operation

- Material loading

- Process monitoring

This reduces training time and makes it easier to maintain consistent brand presentation even when staff changes.

Long-Term Brand Protection Through Process Stability

Brand recognition is built over time. Inconsistent presentation erodes trust gradually, often without immediate feedback.

Automatic labeling machines provide long-term stability by:

- Maintaining calibration over long cycles

- Reducing wear-related variation

- Ensuring consistency across years of production

This protects brand value not just today, but as the company grows and enters new markets.

Summary Table: Impact of Automatic Labeling Machines on Brand Recognition

Aspect | Manual Labeling | Automatic Labeling Machine

Label position | Operator-dependent | Fixed and repeatable

Orientation | Variable | Consistent and precise

Visual quality | Inconsistent | Clean and professional

Production speed | Limited | Matches automated lines

Brand consistency | Difficult to maintain | Highly standardized

Scalability | Low | High

Why Brand Recognition Improves Even Without Changing the Label Design

An important insight is that automatic labeling improves brand recognition without changing the label itself.

The same logo, fabric, and color can deliver very different brand impact depending on how consistently they are presented. Automatic labeling machines amplify the value of existing brand assets by ensuring they are displayed correctly every time.

This makes labeling automation one of the most cost-effective branding investments in manufacturing.

From Manufacturing Detail to Brand Strategy

Labeling is often treated as a minor production detail. In reality, it is a direct interface between manufacturing and branding.

By automating labeling, mattress manufacturers:

- Align production with brand strategy

- Reduce risk to brand image

- Create a professional and unified product appearance

This alignment becomes increasingly important as competition intensifies.

Conclusion: Automatic Labeling as a Brand-Building Tool

Automatic labeling machines do far more than save labor or increase speed. They transform labeling into a controlled, repeatable process that actively supports brand recognition.

By standardizing label placement, improving visual quality, reducing human variability, and integrating seamlessly into automated production lines, these machines help mattress manufacturers present a strong, consistent brand image at scale.

For mattress companies seeking to strengthen brand identity through product-level details, automatic labeling machines are not a minor upgrade. They are a strategic tool for building recognition, trust, and long-term brand value.