How Does the Use of Robotic Arms in Mattress Production Enhance Quality and Speed?

The mattress manufacturing industry is undergoing a transformation with the integration of robotic arms. These automated systems enhance production speed, ensure consistent quality, and improve workplace safety. By automating repetitive and precision-based tasks, robotic arms allow manufacturers to increase output, reduce defects, and optimize material usage. In this article, we will explore how robotic arms revolutionize mattress production by enhancing quality, improving speed, and ensuring efficiency.

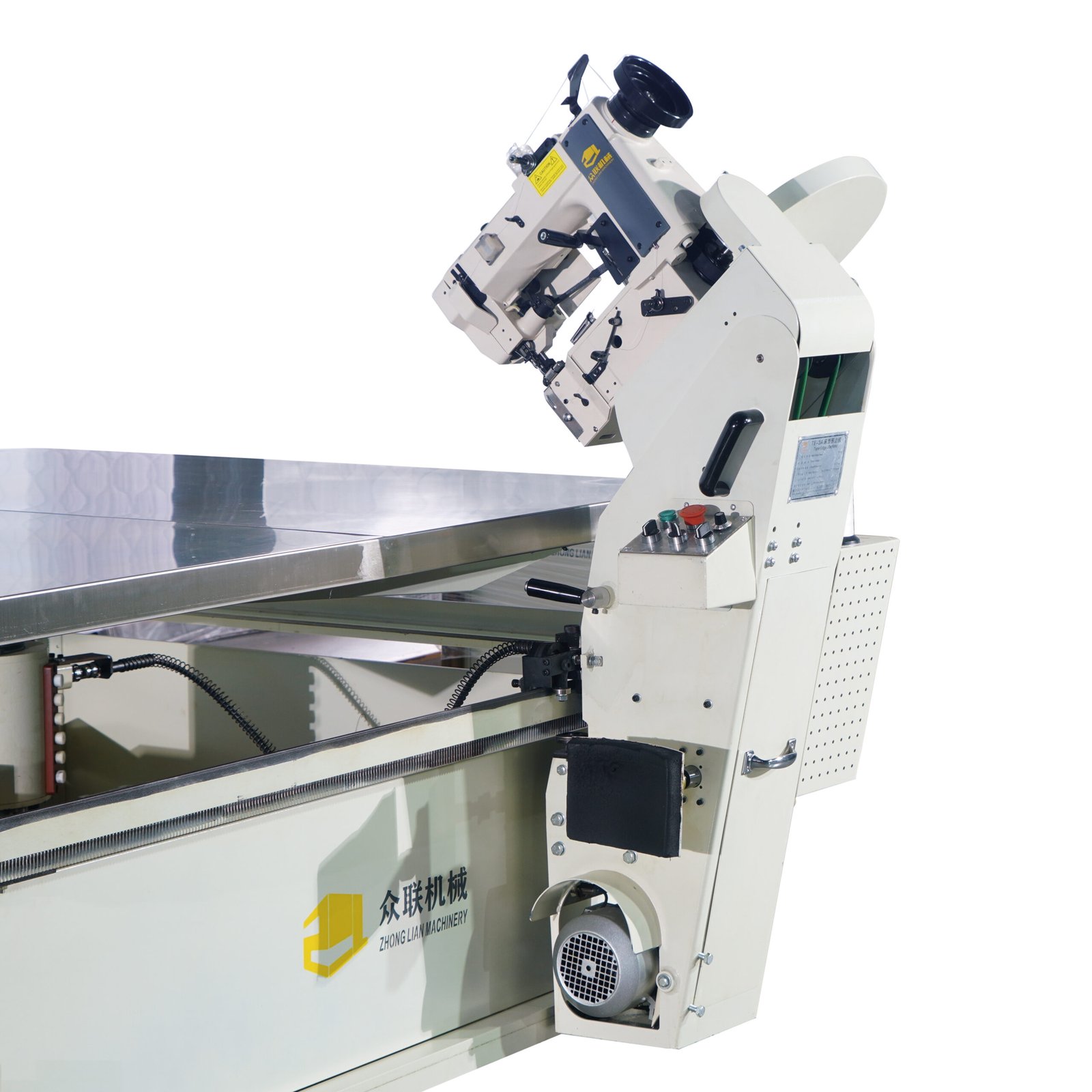

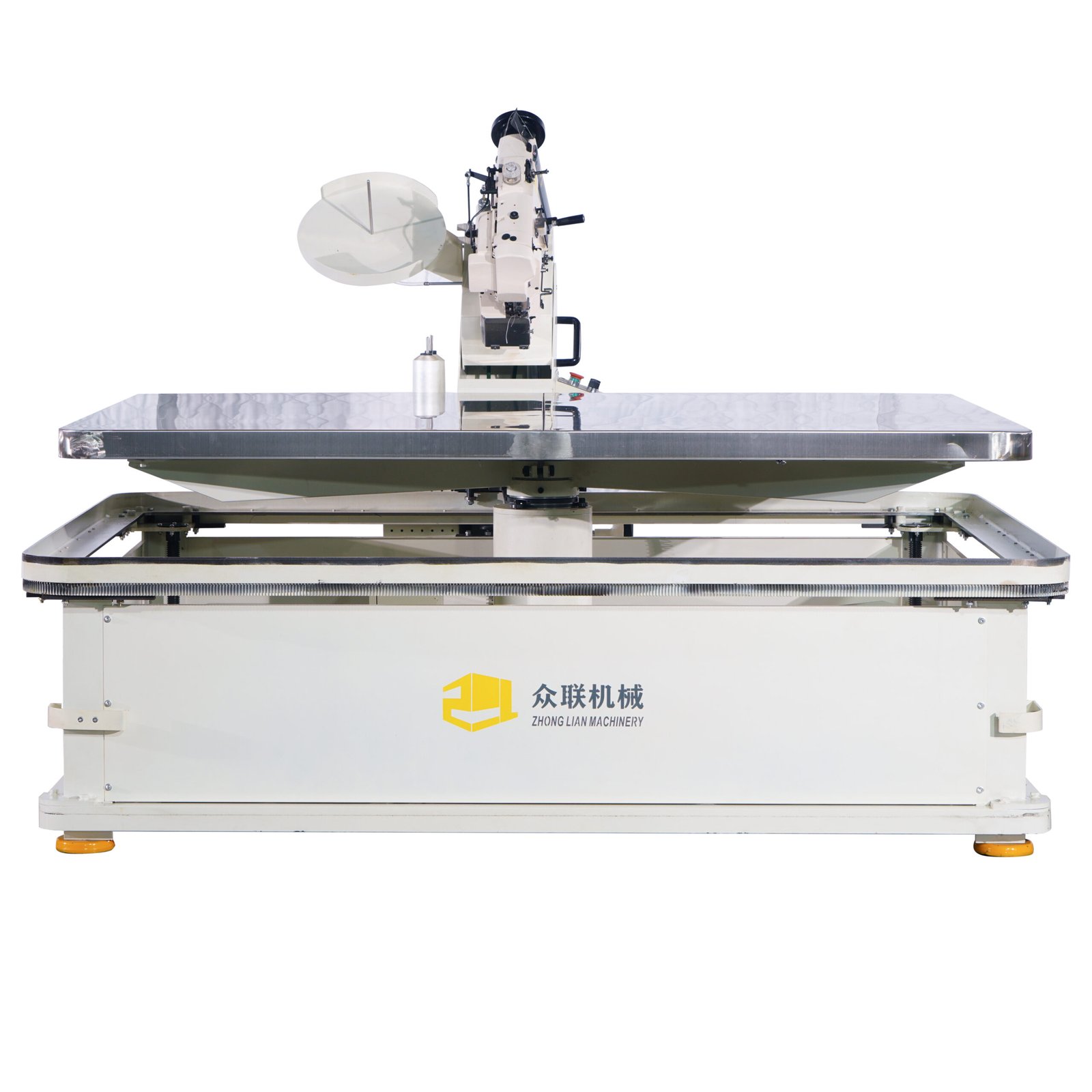

How Do Robotic Arms Improve Precision in Cutting and Sewing?

One of the key factors affecting mattress quality is the accuracy of cutting and sewing. Even minor inconsistencies in stitching or fabric alignment can lead to structural weaknesses in the final product.

How do robotic arms improve precision?

✅ Automated Fabric Cutting: Robotic arms cut materials with pinpoint accuracy, ensuring consistent dimensions and reducing material waste.

✅ High-Precision Stitching: Robotic sewing systems execute flawless stitching patterns, preventing loose threads and uneven seams.

✅ Consistency Across Products: Unlike manual labor, robotic arms eliminate human error, ensuring that every mattress meets exact specifications.

By improving precision, robotic arms ensure higher product quality, reduce defects, and minimize material wastage.

How Do Robotic Arms Speed Up Mattress Production?

Traditional mattress production relies heavily on manual labor, which is time-consuming and prone to fatigue-related errors. Robotic arms work continuously without breaks, dramatically increasing production speed.

How do robotic arms increase efficiency?

⚡ Continuous Operation: Unlike human workers, robots operate 24/7, significantly increasing output.

🛠️ Automated Workflow: Robots streamline tasks from material handling to sewing and stitching, reducing processing time.

🚀 Faster Assembly Lines: Integrated robotic systems accelerate mattress assembly without compromising quality.

With robotic automation, manufacturers reduce production time by up to 50%, enabling them to meet high demand efficiently.

How Do Robotic Arms Improve Product Consistency?

Consistency is crucial in mattress production. Even slight variations in sewing tension, material alignment, or foam cutting can lead to customer dissatisfaction and product returns.

How do robotic arms ensure uniformity?

📏 Precision Programming: Every robotic arm follows pre-programmed instructions, ensuring each mattress is identical in size, shape, and structure.

🔄 Adaptive Stitching Adjustments: AI-powered robotic arms adjust in real time to maintain consistent stitch length and tension.

✅ Eliminating Manual Variations: Unlike human workers, robots maintain uniform speed and pressure, preventing fabric distortions.

With robotic precision, manufacturers can achieve 99% consistency across all mattresses, ensuring customer satisfaction and brand reliability.

How Do Robotic Arms Enhance Workplace Safety?

Mattress production involves heavy lifting, repetitive tasks, and exposure to sharp tools, all of which pose risks to workers. By automating dangerous processes, robotic arms reduce workplace injuries.

How does automation improve worker safety?

🦾 Eliminating Repetitive Strain Injuries: Robots handle monotonous, physically demanding tasks, reducing worker fatigue.

⚙️ Minimizing Human Contact with Sharp Tools: Automated cutting and sewing reduce the risk of accidental cuts or punctures.

🏗️ Safer Heavy Material Handling: Robots lift and transport heavy materials, preventing back strain and musculoskeletal disorders.

By reducing injury risks, robotic arms create a safer, healthier work environment while maintaining high production efficiency.

How Do Robotic Arms Optimize Material Usage?

Material waste is a major concern in mattress manufacturing. Robotic arms optimize material cutting and stitching, ensuring maximum utilization of raw materials.

How does automation reduce waste?

🔍 Smart Material Cutting: AI-driven robots analyze patterns to minimize fabric and foam waste.

♻️ Efficient Thread and Stitching Management: Automated sewing ensures no excess thread usage and precise material consumption.

🔄 Integrated Recycling Systems: Robotic systems categorize and process waste for repurposing and recycling.

By implementing robotic material handling, factories can reduce raw material waste by 30%, making production more cost-effective and sustainable.

How Do Robotic Arms Support Customization?

Consumer demand for custom mattresses is rising, requiring manufacturers to offer flexible production capabilities. Robotic arms enable efficient customization without slowing down production.

How do robotic arms support customization?

🎨 Programmed Stitching Variations: Robots adjust sewing patterns to match different mattress designs.

📏 Adaptive Cutting for Custom Sizes: Automated systems precisely cut foam and fabric for personalized dimensions.

🔄 Quick Configuration Changes: With AI-powered control, robotic arms switch between standard and custom orders seamlessly.

Robotic technology makes mass customization scalable, allowing manufacturers to cater to diverse consumer preferences efficiently.

How Do Robotic Arms Integrate with Smart Manufacturing?

Modern mattress factories are shifting toward smart manufacturing, where robotic arms integrate with AI and IoT to create a fully automated ecosystem.

How does smart automation enhance production?

📡 Real-Time Data Monitoring: AI-powered systems track robot performance and detect inefficiencies.

⚙️ Predictive Maintenance: Sensors analyze machine wear and schedule maintenance before breakdowns occur.

🔄 Seamless Production Adjustments: Robots automatically adapt to material changes and production demands.

With robotic and AI integration, mattress manufacturers achieve higher efficiency, minimal downtime, and consistent quality control.

How Do Robotic Arms Reduce Long-Term Labor Costs?

Although robotic arms require an initial investment, their long-term cost savings far outweigh upfront costs.

How do robotic arms cut labor expenses?

💰 Fewer Manual Workers Needed: Robots perform tasks previously handled by multiple employees, reducing wage expenses.

🔄 Lower Turnover and Training Costs: Automated systems eliminate the need for constant hiring and retraining.

📈 Increased Productivity: Robots maintain higher production rates without overtime pay.

By reducing long-term labor expenses, robotic automation boosts profitability while maintaining high-quality output.

Conclusion

Robotic arms have revolutionized mattress production, improving quality, speed, and efficiency. By ensuring precision cutting, faster assembly, material optimization, and seamless customization, robotic automation allows manufacturers to meet growing market demands while reducing costs.

As smart manufacturing continues to evolve, robotic technology is set to become the future of mattress production—delivering higher-quality products at unprecedented speeds. 🚀💡

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com