How to Create Refined Mattress Side Patterns with a Four-Head Tack & Stitch Machine

In today’s mattress market, visual differentiation has become just as important as internal structure and comfort performance. While springs, foams, and fabrics determine how a mattress feels, side border patterns determine how a mattress is perceived. A clean, symmetrical, and refined side pattern instantly communicates craftsmanship, quality, and brand positioning.

For many factories, however, achieving consistent and attractive side patterns remains a challenge. Manual or single-head processes often lead to uneven spacing, inconsistent depth, and visible variation between mattresses. As production volume increases, these issues become more pronounced.

This is where the four-head tack and stitch machine plays a critical role. By combining multi-point operation, synchronized motion, and standardized control, it enables manufacturers to produce refined mattress side patterns at scale.

This article explains how four-head tack and stitch machines are used to create high-quality mattress side patterns, focusing on process logic, equipment advantages, and production value rather than surface-level decoration.

For reference to related equipment and integrated production solutions, you may consult the internal company page:

https://mattressmachineryzl.com/

Why Mattress Side Patterns Matter More Than Ever

The side border is one of the few parts of a mattress that customers consistently see and touch. Even when a mattress is covered with bedding, the side panel remains visible in retail displays and home environments.

Well-executed side patterns serve multiple purposes:

- Enhance visual depth and texture

- Reinforce brand identity

- Improve perceived durability

- Create a premium appearance without changing core materials

In contrast, poorly executed patterns—uneven tacks, misaligned rows, or inconsistent spacing—immediately signal low process control, regardless of the mattress’s internal quality.

Limitations of Traditional Side Pattern Processes

Traditional side pattern creation often relies on manual or single-head equipment. While these methods can produce acceptable results at low volume, they face clear limitations.

Common issues include:

- Inconsistent spacing between pattern points

- Uneven depth due to manual pressure variation

- Misalignment between left and right sides

- High dependence on operator experience

As production speed increases, maintaining visual consistency becomes increasingly difficult. Quality becomes reactive, requiring inspection and correction rather than being built into the process.

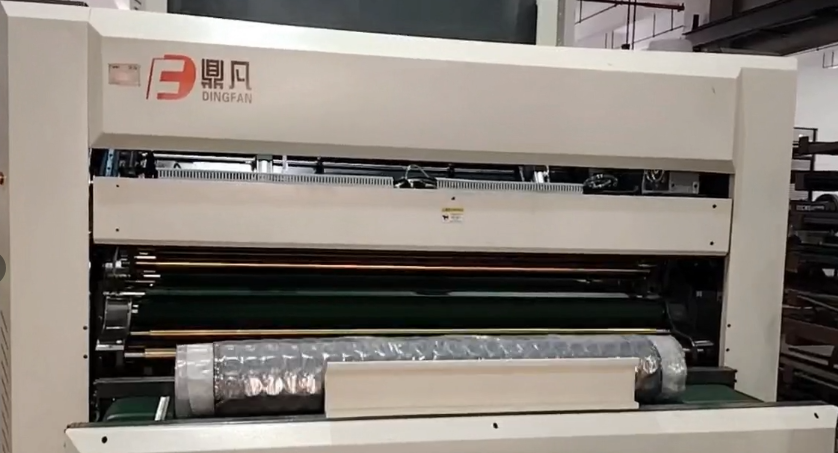

What Defines a Four-Head Tack & Stitch Machine

A four-head tack and stitch machine is designed to operate multiple stitching or tacking points simultaneously. Instead of forming one point at a time, the machine executes four points in a synchronized motion.

Key characteristics include:

- Multi-head synchronized operation

- Uniform pressure and penetration control

- Fixed geometric spacing between heads

- Machine-controlled positioning and timing

This structure allows patterns to be created as a system rather than as a series of individual actions.

Pattern Geometry Through Fixed Head Spacing

One of the most important advantages of a four-head system is geometric consistency.

Because the spacing between heads is fixed and controlled by the machine structure:

- Distance between pattern points is uniform

- Alignment remains consistent along the entire side panel

- Symmetry is preserved from mattress to mattress

This eliminates one of the most common visual defects in manual processes: drifting or irregular spacing.

Consistent Depth and Visual Texture

Visual quality is not only about spacing, but also about depth.

In manual or semi-automatic processes, penetration depth varies depending on operator pressure, material resistance, and fatigue. This leads to patterns that look uneven or shallow in certain areas.

Four-head machines apply pressure through controlled mechanisms, ensuring:

- Uniform penetration depth

- Balanced visual texture

- Consistent shadow and dimensional effect

The result is a refined, high-end appearance that remains consistent across large production batches.

Synchronization with Side Border Feeding

Creating clean patterns requires precise coordination between pattern formation and side border movement.

Four-head tack and stitch machines are designed to synchronize pattern execution with feeding speed. Each pattern point is formed at the correct position relative to fabric movement.

This synchronization prevents:

- Overlapping patterns

- Irregular intervals

- Distorted designs during acceleration or deceleration

As a result, patterns remain straight and evenly distributed along the mattress perimeter.

Reduced Operator Dependency and Improved Repeatability

One of the most significant advantages of four-head systems is reduced reliance on operator skill.

Instead of manually judging spacing, timing, and pressure, operators:

- Set parameters

- Monitor operation

- Manage material flow

This shift dramatically improves repeatability. Quality becomes consistent across shifts, operators, and production days, which is essential for brand-focused manufacturers.

Adaptability to Different Pattern Designs

Four-head machines are not limited to a single pattern style. By adjusting parameters and layouts, manufacturers can create:

- Linear decorative rows

- Repeating geometric motifs

- Dense or sparse pattern arrangements

This flexibility allows factories to offer visual variety without changing equipment, supporting multiple product lines and market segments.

Performance at High Production Volume

Visual processes often become bottlenecks in high-volume factories. Manual pattern creation slows down the line and introduces variability.

Four-head tack and stitch machines maintain pattern quality even at higher speeds because:

- Multiple points are formed simultaneously

- Motion paths are optimized

- Operator intervention is minimized

This makes them suitable for factories aiming to combine high output with premium appearance.

Integration with Side Border Sewing and Finishing Lines

In modern mattress factories, side pattern creation is rarely an isolated process. It is often integrated with:

- Side border sewing

- Tape edging

- Automated feeding and conveying systems

Four-head machines are designed to fit into these integrated lines, ensuring smooth material flow and consistent orientation.

More information about integrated production concepts can be found internally at:

https://mattressmachineryzl.com/

Long-Term Stability and Quality Retention

Consistency must be maintained not just during initial setup, but over long production cycles.

Four-head machines are designed for mechanical stability, ensuring:

- Minimal drift in spacing

- Stable penetration depth over time

- Reduced need for frequent recalibration

This long-term stability protects visual quality and reduces hidden rework costs.

Summary Table: Benefits of Four-Head Tack & Stitch Machines for Side Patterns

Process Aspect | Traditional Single-Head Method | Four-Head Tack & Stitch Machine

Pattern spacing | Operator-dependent | Fixed and uniform

Penetration depth | Variable | Consistent and controlled

Visual symmetry | Inconsistent | Highly symmetrical

Production speed | Limited | High and stable

Labor dependency | High | Significantly reduced

Repeatability | Low | High across batches

Why Four-Head Systems Support Brand-Level Consistency

For brands selling through retail or export channels, visual consistency is non-negotiable. Customers expect every mattress to look identical, regardless of when or where it was produced.

Four-head tack and stitch machines support this requirement by:

- Standardizing pattern geometry

- Eliminating operator-induced variation

- Enabling scalable production

They allow visual design to become a controlled process rather than a subjective outcome.

Conclusion: Turning Side Patterns into a Controlled Manufacturing Process

Creating refined mattress side patterns is not about decoration alone. It is about process control, repeatability, and brand consistency.

Four-head tack and stitch machines transform side pattern creation from a manual, experience-driven task into a structured and repeatable operation. By controlling spacing, depth, synchronization, and symmetry, they enable manufacturers to achieve premium visual quality at industrial scale.

For mattress factories seeking to elevate product appearance without sacrificing efficiency or consistency, four-head tack and stitch machines provide a practical and proven path forward.