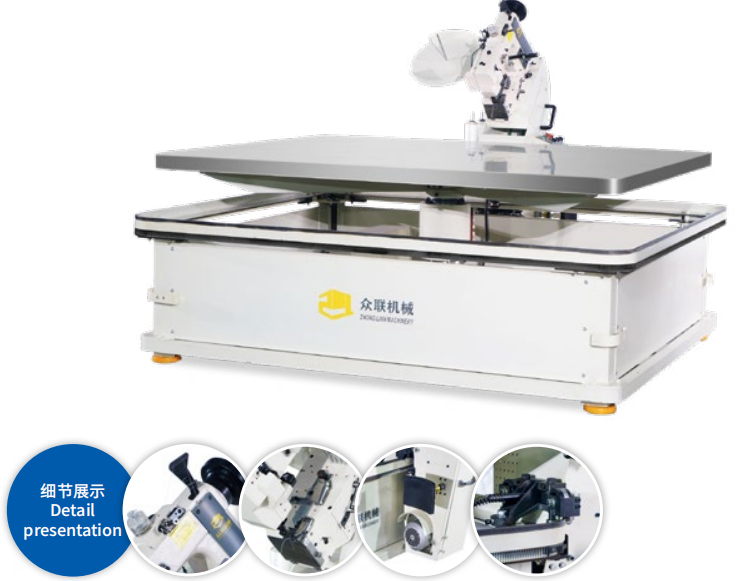

Primarily used for mattress edge binding.

1. Frequency converter speed regulation with automatic corner deceleration ensures premium product quality;

2. Button-controlled worktable elevation and head tilt adjustment for operational convenience

3. User-friendly interface with stable operation, minimal vibration, and low noise;

4. Electronic clutch control for smooth start-stop transitions.

Table Of Contents For Mattress Tape Edge Sewing Machine

Application Of Mattress Tape Edge Sewing Machine

| Item | Specification |

|---|---|

| Production efficiency | 10–15 sheets/hour |

| Sewing thickness | 30–450 mm |

| Head lifting range | 280 mm |

| Machine size (L×W×H) | 1720 × 2120 × 900 mm |

| Max speed | 2800 RPM |

| Total weight | 600 kg |

| Total power | 1.0 kW |

| Rated power supply | 380/220 V, 50/60 Hz |

How to Choose the Right Mattress Tape Edge Machine?

Step 1: Know Your Production Scale

| Factory Type | Daily Output | Recommended Machine Type |

|---|---|---|

| Small Workshop | ≤20 beds/day | Semi-Automatic (3A series) |

| Medium Factory | 50–100 beds | Full-Auto (4B series, 5-needle head) |

| Large Plant | 200+ beds | Full-Auto (5B series, CNC control) |

Step 2: Match Your Mattress Specs

| Mattress Feature | Key Machine Parameters to Match |

|---|---|

| Extra Thick (>40cm) | Adjustable sewing height: up to 45–50cm |

| High Precision Needed | Stitch tolerance ≤±1mm, servo motor control |

| Mixed Materials | Compatibility with fabric, leather, and non-woven |

| Curved Corner Design | Auto corner-turning & needle lift synchronization |

Table Of Contents For This Page

It is not easy to introduce all aspects of custom wood, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

Common Questions

Most Popular Questions.

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

We offer both food-grade borosilicate glass and soda-lime glass, each fully tested for thermal shock resistance and chemical stability.

Yes—choose any volume from 4 oz to 32 oz, straight or tapered walls, and clear, amber or any custom tint.

We supply metal screw-on lids (plain or with straw hole), bamboo lids, and plastic snap-on caps—all compatible with our jar neck finish.

Standard MOQ is 500 pcs per SKU. Tiered pricing and volume discounts kick in at 1,000 pcs, 5,000 pcs and above.

Rapid 3–5 day turnaround: includes a 3D render plus a physical prototype, with a refundable fee of USD 50–100.

We run a 12-step QC process—from raw-material inspection through final assembly—ensuring ≥ 99.98 % pass rate on every batch.

Our factory is ISO 9001 and GMP certified, and our jars carry FDA, LFGB and REACH approvals, with full third-party test reports.

Multi-layer protection (EPE foam, honeycomb paper, wooden crates) plus cargo insurance and complete customs documentation for global delivery.