Personalized Customization: The Diverse Options of Mattress Packaging Machines

Personalized Customization: The Diverse Options of Mattress Packaging Machines

Why Customize a Mattress Packaging Machine?

Every mattress factory has unique packaging needs based on:

✔ Different mattress sizes & thicknesses

✔ Choice of packaging materials

✔ Branding & marketing customization

✔ Automation levels for efficiency

Customizing a mattress packaging machine ensures higher efficiency, cost savings, and enhanced product protection. Let’s explore the 8 key customization options available today.

1️⃣ Adjustable Sizing for Various Mattress Types

Why Is Size Flexibility Important?

✔ Handles different mattress sizes – Twin, Queen, King, and custom sizes

✔ Adjusts for different mattress thicknesses – Standard, extra-thick, and roll-packed mattresses

✔ Ensures a perfect fit – Reduces packaging material waste

Customization Options

📌 Automatic size detection – Machine auto-adjusts to mattress dimensions

📌 Adjustable compression settings – Ensures compact & secure packaging

📌 Multiple preset size options – Fast switching between mattress sizes

📌 Example: A manufacturer upgraded to auto size detection, reducing manual adjustments by 60%.

2️⃣ Material Compatibility for Diverse Packaging Needs

What Packaging Materials Can Be Used?

✔ Plastic film – Lightweight & moisture-resistant

✔ Vacuum-sealed bags – Space-saving for easy shipping

✔ Eco-friendly biodegradable packaging – Sustainable & customer-friendly

Customization Options

📌 Multi-material feeder – Works with various packaging materials

📌 Adjustable tension control – Prevents film tearing & ensures tight wrapping

📌 Eco-packaging compatibility – Supports sustainable materials

📌 Example: A factory switched to biodegradable film, reducing plastic waste by 40%.

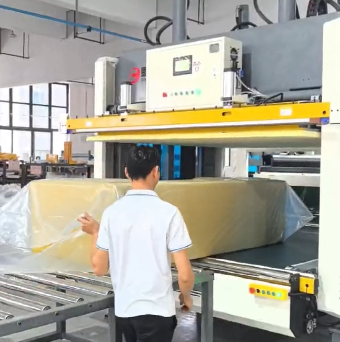

3️⃣ Automation Levels: Semi vs. Fully Automatic

How Does Automation Improve Efficiency?

✔ Semi-automatic – Requires manual loading but automates sealing/wrapping

✔ Fully automatic – Conveyor-fed, robotic handling, minimal human input

✔ AI-powered adjustments – Optimizes packaging settings in real time

Customization Options

📌 Robotic arms for handling – Automates stacking & movement

📌 Automated conveyor integration – Seamless flow from production to packaging

📌 Touchscreen interface – Simplifies machine operation

📌 Example: A company upgraded to full automation, cutting packaging time by 50%.

4️⃣ Advanced Sealing Techniques for Better Protection

Why Is Sealing Important?

✔ Prevents moisture, dust & contamination

✔ Ensures strong, durable packaging

✔ Minimizes product returns due to damage

Customization Options

📌 Heat sealing – Creates a strong, air-tight seal

📌 Ultrasonic sealing – Clean, precise, and energy-efficient

📌 Adhesive sealing – Uses glue/tape for added security

📌 Example: A factory switched to ultrasonic sealing, improving sealing strength by 35%.

5️⃣ Branding & Labeling for Market Differentiation

Why Add Branding to Packaging?

✔ Enhances brand recognition 💡

✔ Includes product details for logistics 📦

✔ Supports barcode tracking & scanning 📲

Customization Options

📌 Custom logo printing – Directly on packaging film

📌 QR/barcode integration – Easier inventory & tracking

📌 Automated label applicators – No manual labeling required

📌 Example: A business added custom barcode labels, reducing inventory errors by 40%.

6️⃣ Protective Features for Damage-Free Shipping

How to Prevent Transit Damage?

✔ Reinforced packaging film – Stronger protection against external impact

✔ Edge & corner protectors – Prevents dents & structural damage

✔ Shock-absorbing layers – Minimizes handling damage

Customization Options

📌 Built-in corner protection – Extra reinforcement for delicate areas

📌 Multiple wrapping layers – Ensures durability

📌 Anti-tear materials – Prevents ripping during transit

📌 Example: A manufacturer added corner protectors, reducing customer complaints by 30%.

7️⃣ Energy Efficiency & Eco-Friendly Features

Why Optimize Energy Consumption?

✔ Lowers electricity bills 🔋

✔ Reduces environmental footprint 🌱

✔ Meets sustainability standards ✅

Customization Options

📌 Power-saving mode – Reduces idle power usage

📌 Energy-efficient motors – Uses less power per cycle

📌 Solar-powered integration – Runs on renewable energy

📌 Example: A factory cut energy consumption by 25% by upgrading to low-power motors.

8️⃣ Integration With Existing Production Lines

Why Is System Integration Important?

✔ Faster production flow 🚀

✔ Less manual handling 🙌

✔ Minimized downtime ⏳

Customization Options

📌 Smart conveyor belt sync – Matches existing production speed

📌 IoT monitoring – Real-time performance tracking

📌 AI-based troubleshooting – Detects & auto-fixes machine errors

📌 Example: A factory cut downtime by 30% with IoT machine monitoring.

📌 Quick Comparison: Key Customization Options

| Customization Factor | Customization Features | Why It Matters? |

|---|---|---|

| Adjustable Sizing 📏 | Auto-detect mattress size | Handles various mattress dimensions easily |

| Material Compatibility 📦 | Plastic, vacuum bags, eco-materials | Reduces waste & improves durability |

| Automation Levels 🤖 | Semi-auto to fully automated | Increases speed & reduces labor costs |

| Sealing Techniques 🔥 | Heat, ultrasonic, adhesive sealing | Ensures strong, protective packaging |

| Branding & Labeling 🏷 | Custom prints & barcodes | Enhances tracking & marketing |

| Protective Features 🛡 | Edge protectors & shock-proof wrapping | Reduces damage during shipping |

| Energy Efficiency ⚡ | Low-power motors & auto shutoff | Saves energy & lowers costs |

| Production Line Integration 🔗 | Conveyor sync & remote monitoring | Streamlines factory operations |

✔ Are you customizing your packaging machine for maximum efficiency?

🔚 Conclusion: Why Customization Matters

💡 A fully customized mattress packaging machine = More efficiency, better product protection & cost savings!

By adjusting size, materials, automation, sealing & branding, manufacturers can:

✔ Reduce labor & packaging costs 💰

✔ Increase packaging speed & output 🚀

✔ Improve brand recognition & logistics 🏷

✔ Minimize transit damages & returns 📦

📌 Final Tip: Invest in a flexible packaging machine that meets both current & future needs! ✅

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com