Can’t find the answer? Reach out to our customer support team.

Why Intelligent Production Lines Are Safer and More Efficient Than Traditional Manufacturing Models

In mattress manufacturing, production efficiency and workplace safety have traditionally been treated as two separate objectives. Management teams often assume that increasing speed raises safety risks, while stricter safety measures reduce output. This trade-off mindset

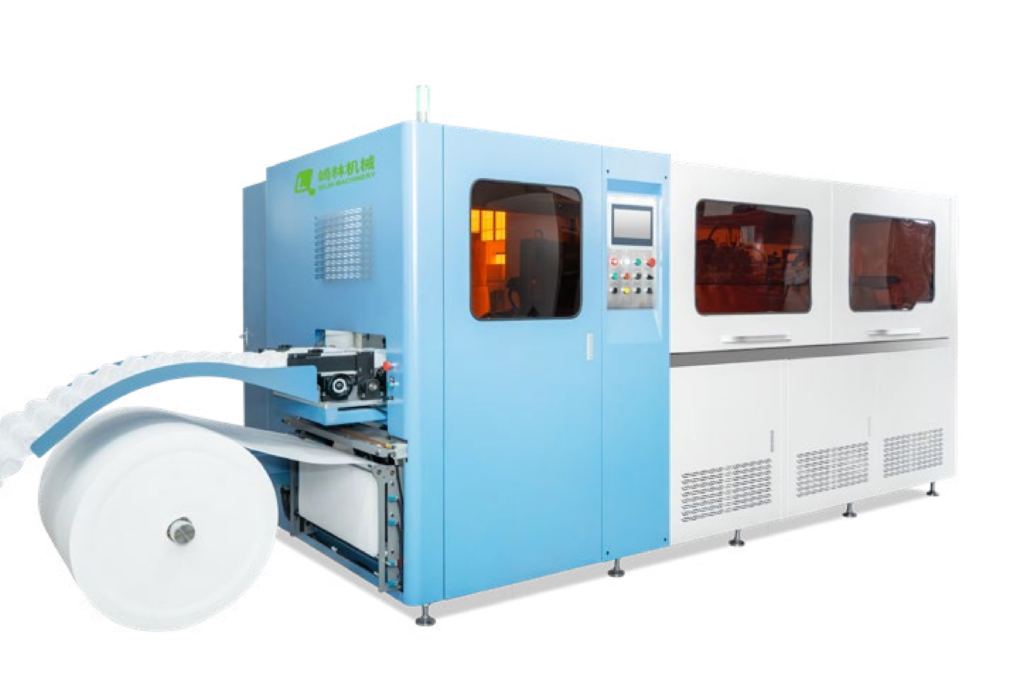

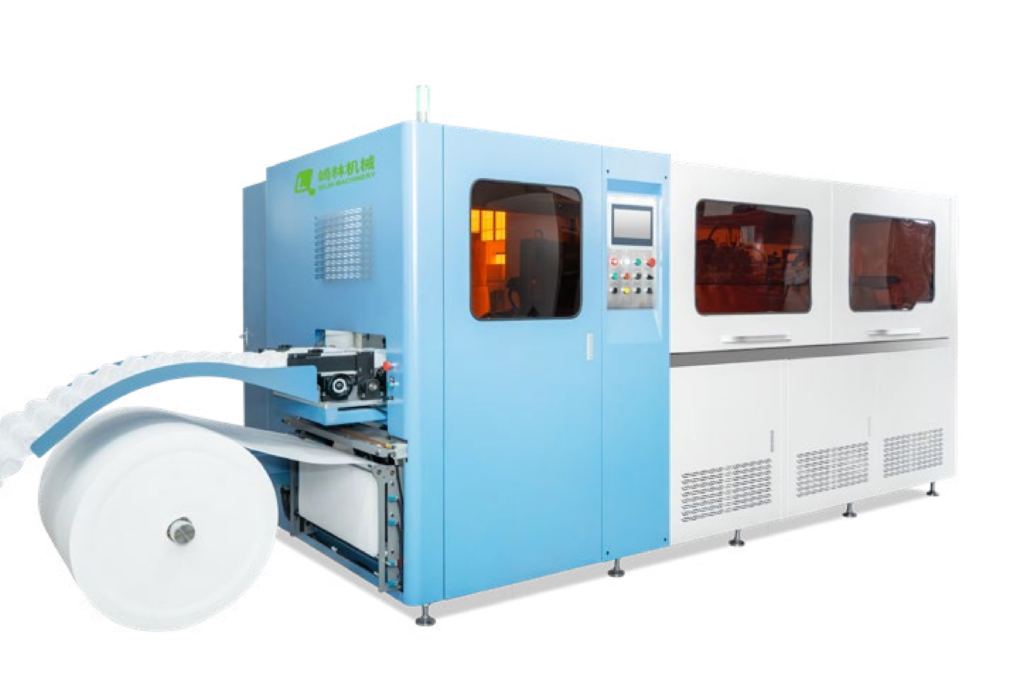

The Intelligent Upgrade Path for Mattress Manufacturing Factories

In the global mattress industry, competition is no longer driven only by product design or raw material selection. It is increasingly shaped by manufacturing capability. Rising labor costs, growing product complexity, shorter delivery cycles, and

How Automatic Layer-Changing Machines Improve Efficiency in Multi-Layer Mattress Production Lines

In modern mattress manufacturing, product structure is becoming increasingly complex. Multi-layer constructions that combine springs, foams, pads, nonwoven materials, and fabrics are now the norm rather than the exception. While these structures improve comfort and