The Importance of Mattress Flanging Machines in Production?

Too much manual sewing slows production and causes errors? You’re not alone.

Mattress flanging machines automate border stitching, reduce defects, and speed up your entire production line with precision and consistency.

If you’re struggling to scale mattress production while maintaining consistent quality, flanging machines might be the game-changer you’re looking for.

What exactly does a mattress flanging machine do?

Manual stitching takes time and often lacks consistency. This impacts the look and durability of your mattress.

Mattress flanging machines stitch the mattress border to the top and bottom panels automatically, speeding up the process and improving uniformity.

Dive deeper: Understanding the stitching process

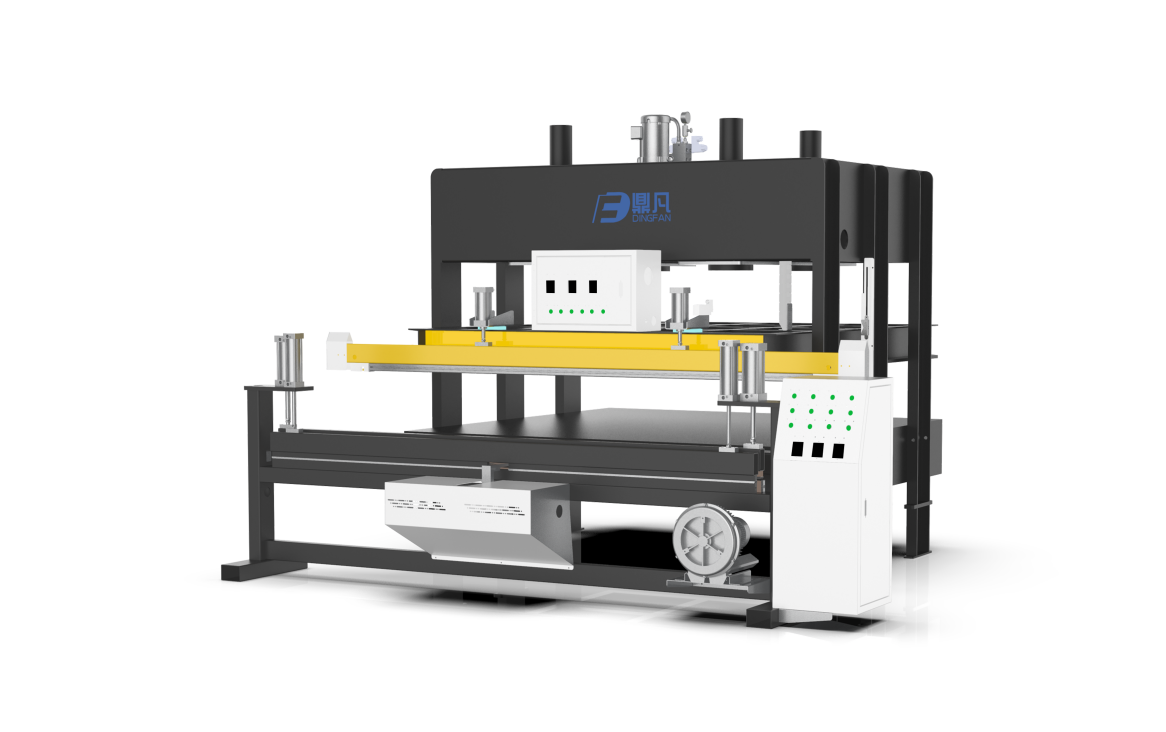

🧵 Core Components

Flanging machines consist of:

- A high-speed sewing head

- Border and panel guide rails

- Height-adjustable work table

- Pneumatic lifting systems

- User control interface (often touch screen)

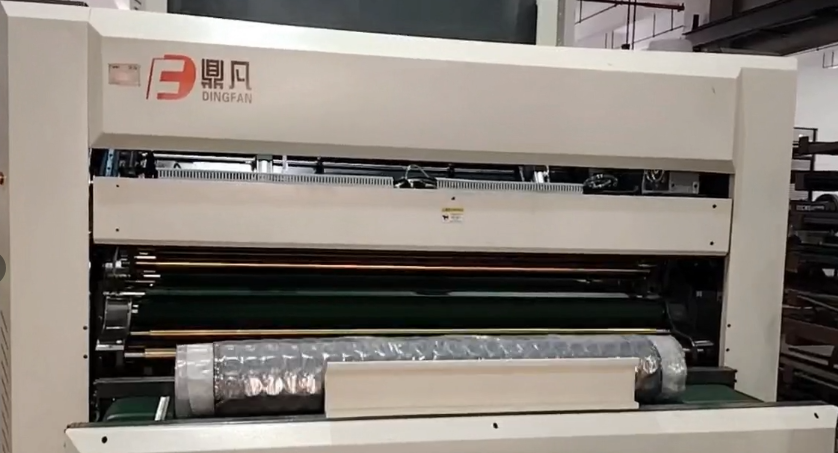

Once the top and bottom panels are quilted, the flanging machine sews the border fabric to both sides, preparing the mattress unit for tape edging.

🔄 Automation Benefits

With automation, stitching speed increases 3–4x compared to manual operation. Operators only need to load and unload panels. Some models also auto-reposition the panel mid-process.

| Component | Function |

|---|---|

| Sewing Head | Creates precise, consistent stitches |

| Border Guide | Ensures even attachment of the side fabric |

| Servo Drive System | Controls stitching speed and pressure |

| Foot Lift Mechanism | Raises/lowers mattress during operation |

This machine turns what was once a bottleneck into a fast, stable, and quality-assured process.

How do flanging machines improve production speed?

Still relying on manual labor for border stitching? You’re losing time—and money.

Flanging machines can double or triple output compared to manual sewing by standardizing and automating panel assembly.

Dive deeper: From slow line to fast lane

⏱️ Stitching Speeds

Typical manual border stitching: ~2–3 units/hour

Flanging machine: 8–12+ units/hour

👨🏭 Reduced Labor Dependence

One trained operator can handle one flanging station, often supporting two lines in parallel.

📈 Higher Throughput

When bottlenecks are removed from border assembly, the overall line speed improves. That boosts shift output and lowers cost per unit.

| Metric | Manual Stitching | Flanging Machine |

|---|---|---|

| Units/hour | 2–3 | 8–12+ |

| Labor required | 2–3 workers | 1 operator |

| Downtime | Frequent | Minimal |

| Stitch accuracy variation | High | Low |

When I switched to automated flanging for our double-size panels, my daily production jumped by 60%—with no extra staff.

What quality improvements do flanging machines bring?

Uneven stitching and weak seams can lead to warranty issues or product returns.

Flanging machines create uniform seams with precise tension, which improves product durability and reduces failure rates.

Dive deeper: From functional to flawless

🔍 Tension Control

Integrated tension sensors in modern machines ensure thread tension is automatically adjusted during operation. This prevents skipped stitches or loose seams.

📏 Uniform Stitch Length

Unlike manual sewing, where stitch length often varies, flanging machines maintain consistent spacing, improving structural strength and visual appearance.

🛏️ Long-Term Durability

A uniform flange seam ensures the mattress won’t split open even under years of compression and edge loading. This is crucial for hospitality-grade products or heavier mattress models.

| Quality Factor | Manual Sewing | Flanging Machine |

|---|---|---|

| Stitch Consistency | Inconsistent | Uniform |

| Tension Control | Manual (high variance) | Automated & precise |

| Warranty Claim Risk | Higher | Significantly reduced |

In short, a stronger flange means fewer callbacks and longer mattress lifespan.

What’s the cost-benefit of using flanging machines?

Worried about the investment? Let’s talk numbers.

Although flanging machines require upfront cost, they reduce labor, waste, and warranty repairs—paying for themselves within months.

Dive deeper: ROI and operational savings

💰 Labor Savings

Switching from 3 workers to 1 operator per line cuts monthly wage bills by 30–40%.

🧵 Material Efficiency

Reduced thread waste and panel misalignment means lower rejection rates.

📦 Warranty Reduction

Stronger seams = fewer returns. One fewer refund per week can save thousands annually.

| Cost Metric | Manual Process | With Flanging Machine |

|---|---|---|

| Labor (monthly) | $4,000–6,000 | ~$2,000 |

| Waste/Error Rate | 5–8% | <1% |

| Warranty Return Rate | 3–5% | <1% |

| ROI Period | — | 3–5 months |

Flanging isn’t just faster—it’s financially smarter.

Conclusion

Mattress flanging machines speed up production, improve stitching accuracy, reduce labor, and save costs. For any factory scaling mattress output, they’re a must-have.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com