The Key to Improving Mattress Support: Optimizing Pocket Spring Bonding Technology

In mattress structures, pocket springs are often seen as the core component that determines support performance. However, in real manufacturing and long-term use, the spring itself is only part of the equation. What truly determines whether a mattress feels stable, resists sagging, and maintains consistent support over time is the bonding technology between pocket springs.

In many mattress factories, we observe a common situation. Spring specifications look correct, materials meet standards, and initial comfort tests are acceptable. Yet after a period of use, the mattress begins to lose support in certain areas, showing soft zones or uneven firmness.

When these issues are analyzed carefully, the root cause is rarely the spring itself. In most cases, the real problem lies in how the pocket springs are bonded together.

This article explains, from a practical production perspective, how pocket spring bonding technology directly affects mattress support and how systematic process optimization can significantly improve long-term performance.

For reference to relevant equipment and integrated production solutions, you may visit our internal company page:

https://mattressmachineryzl.com/

The Role of Bonding Technology in Defining Mattress Support

Many discussions about mattress support focus on factors such as wire diameter, spring height, or spring count. These parameters are important, but they only define the theoretical support capacity of individual springs.

Actual mattress support is generated by the coordinated behavior of the entire spring unit. This coordination depends on how effectively the pocket springs are bonded to each other.

When bonding is unstable or inconsistent, springs work independently rather than as a system. This leads to uneven load distribution, early fatigue in local areas, and long-term deformation. Therefore, bonding technology does not simply affect whether springs stay together. It defines the lower limit of mattress support performance.

How Pocket Spring Bonding Directly Influences Support Performance

From an engineering perspective, pocket spring bonding affects support in three key ways.

First, it determines lateral stability. Proper bonding restricts horizontal movement between springs, preventing displacement under load and maintaining structural integrity.

Second, it enables load sharing. When bonding is stable, adjacent springs work together to distribute pressure more evenly, reducing stress concentration.

Third, it controls long-term deformation. Consistent bonding ensures uniform rebound behavior, which helps the mattress retain its shape and support characteristics over time.

These factors explain why mattresses with similar spring specifications can feel very different in real use.

Common Bonding Issues That Lead to Weak Support

In production environments, several bonding-related issues frequently undermine mattress support.

One common issue is minimal bonding strength that is just sufficient to pass initial handling. The product appears fine at first but gradually loses integrity during subsequent processes or use.

Another issue is uneven bonding. Some areas are firmly bonded while others are weak, resulting in inconsistent support across the mattress surface.

A third issue is poor process stability. Changes in speed, operators, or specifications cause bonding performance to fluctuate, leading to inconsistent product quality.

These problems are not caused by glue quality alone. They are the result of bonding processes that are not systematically designed or controlled.

Core Principles for Optimizing Pocket Spring Bonding Processes

Effective bonding optimization requires a system-level approach rather than isolated parameter adjustments.

First, the objective should not be simply to make springs stick together, but to form a stable and durable structural unit.

Second, bonding must be considered as part of the entire production rhythm, not as an independent step.

Third, all process parameters should serve the ultimate goal of maintaining stable support performance over the product’s lifespan.

Only with this mindset can bonding optimization deliver real value.

Key Process Factor One: Bonding Pattern Selection and Support Behavior

Common pocket spring bonding patterns include parallel bonding and staggered bonding. Each has a distinct impact on support characteristics.

Parallel bonding creates a regular structure with clear load paths and typically produces a more direct and firm support feel.

Staggered bonding helps reduce lateral stiffness, improves contouring, and distributes localized stress more evenly.

The appropriate bonding pattern should be selected based on mattress positioning, spring specifications, and target comfort profile rather than copying a single standard solution.

Key Process Factor Two: Bonding Stability Matters More Than Maximum Strength

Many factories evaluate bonding quality based solely on pull strength tests. While strength is important, stability is more critical for long-term support.

Stable bonding means consistent performance under repeated loading, uniform behavior across the entire spring unit, and reproducibility from batch to batch.

Overly strong bonding that lacks consistency can still lead to uneven support and unpredictable product behavior.

Therefore, the goal of bonding optimization should be controlled, repeatable, and durable bonding performance.

Key Process Factor Three: Bonding Timing Must Match Production Rhythm

Bonding is a dynamic process that must align with production speed.

If production speed increases without corresponding bonding adjustments, glue may not fully activate before the spring unit moves to the next stage. This can cause internal stress and weak structural connections.

Conversely, mismatched timing can lead to excessive glue spread and inconsistent bonding results.

In modern mattress production, bonding parameters must be synchronized with overall line speed, highlighting the importance of integrated control systems.

Key Process Factor Four: Pressure and Time as Hidden Determinants of Support

Support performance does not form instantly at the moment of bonding. It develops through the combined effect of pressure and time.

Insufficient pressure results in superficial contact between springs. Insufficient pressure duration prevents bonding layers from fully stabilizing.

These issues may not be immediately visible but will manifest as support degradation during use. Proper pressure control and adequate stabilization time are essential for reliable support.

Equipment Compatibility and Process Execution Capability

Even well-designed bonding processes cannot succeed if equipment execution is unstable.

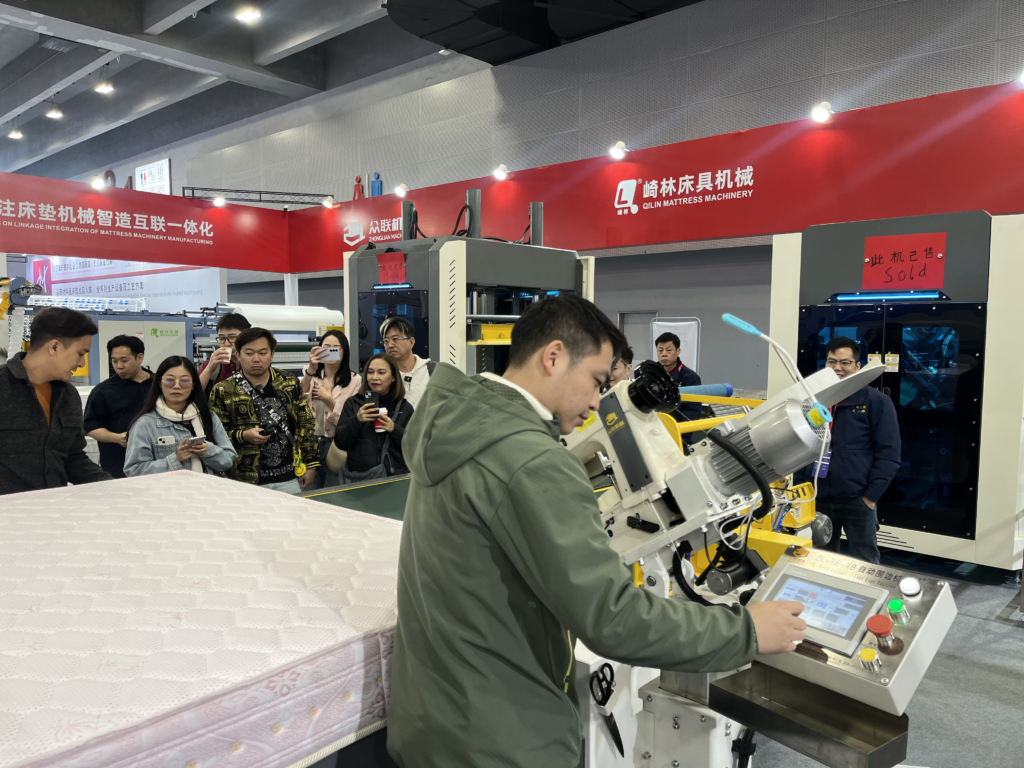

Professional pocket spring bonding equipment provides precise parameter control, consistent mechanical actions, and long-term operational stability. This ensures that optimized processes can be reliably implemented on the production floor.

This is why many manufacturers are moving toward integrated production solutions rather than relying on isolated machines.

Related equipment concepts can be reviewed internally at:

https://mattressmachineryzl.com/

Summary Table: Key Pocket Spring Bonding Factors and Support Impact

Process Dimension | Impact on Mattress Support | Optimization Focus

Bonding pattern | Defines structural cooperation | Select pattern based on mattress positioning

Bonding stability | Determines long-term performance | Ensure consistency across batches

Production rhythm | Affects structural integrity | Synchronize bonding with line speed

Pressure control | Influences compactness | Apply uniform and sufficient pressure

Time control | Affects bonding effectiveness | Allow adequate stabilization time

Equipment capability | Ensures process execution | Maintain controllable and stable operation

Conclusion: Support Is Engineered, Not Adjusted

High-quality mattress support is not achieved through temporary adjustments or trial-and-error fixes. It is the result of systematic engineering that integrates spring design, bonding technology, and production control.

When pocket spring bonding processes are carefully optimized and consistently executed, mattress support becomes stronger, more uniform, and more durable.

If your mattresses meet material specifications but still suffer from support issues in the market, it is worth taking a closer look at the bonding process itself. In many cases, this is the most overlooked yet most critical factor.