Types of Mattress Spring Machines and Their Applications?

Mattress types keep evolving, and the machines behind them must keep pace—or get left behind.

There are four main types of mattress spring machines—Bonnell, pocket, continuous coil, and offset—each serving different production needs based on support type, comfort goals, and market positioning.

Choosing the right machine directly impacts your mattress line’s efficiency, cost, and market appeal. Let’s break them down.

Why Innovation Matters in Mattress Spring Machinery

In today’s mattress market, customization isn’t just a perk—it’s a necessity. Consumers expect beds tailored to their individual comfort needs, whether that’s different firmness zones for shoulders and hips or enhanced edge support for restless sleepers.

That’s where innovation in spring machinery makes all the difference:

- Adaptability: Modern machines can create springs with varying tension in a single mattress, letting manufacturers offer “multi-zone” designs popularized by brands like Tempur-Pedic and Sealy.

- Efficiency Gains: Advances in automation and precision mean factories can switch between spring styles or mattress sizes faster, cutting downtime and waste.

- Competitive Edge: By keeping up with evolving tech, manufacturers stay ahead of trends—like pocket coil layouts that minimize motion transfer, a big selling point in premium markets.

- Meeting Market Demand: As end-users demand more personalized sleep solutions, only nimble manufacturers can deliver—those with the latest machinery are the first to market.

Innovation isn’t just about flashy features. It’s the engine behind better products, smarter production, and satisfied sleepers.

What Are the Primary Types of Mattress Springs?

Market demand shapes the machines you need.

Mattress spring types define comfort levels, motion isolation, and long-term performance. Understanding each type helps you choose the right machine for your product line.

| Spring Type | Shape/Feature | Ideal For |

|---|---|---|

| Bonnell | Hourglass coils | Budget and mid-tier mattresses |

| Individually encased coils | Premium, motion-isolated comfort | |

| Continuous Coil | One-piece interconnected coils | Economical, long-lasting support |

| Offset | Squared-top coils with hinging | Zoned support, multi-position sleepers |

Let’s dive into the machines that build each one.

How Wire Drawing Spring Machines Fit In

Every mattress spring starts somewhere—and that’s with wire drawn to just the right size and strength.

Wire drawing spring machines kick off the process by transforming thick steel rods into precisely sized, high-tensile wire—ready for spring coiling. These rugged machines stretch wire through a series of dies, steadily thinning it while increasing its durability and consistency. Think of it as prepping the canvas before the masterpiece.

Why bother? Simple: the quality of your wire ultimately defines the bounce, longevity, and comfort of every spring in your mattress. Nike, Simmons, and even IKEA all rely on this essential first step to ensure every coil—and every night’s sleep—meets performance standards.

Highlights of modern wire drawing machines:

- Handle massive spools for non-stop production

- Automatically lubricate and align wire for fewer snags

- Deliver uniform thickness, so every spring matches spec

Where does it fit? Right at the starting line. Without high-quality wire, even the most advanced spring machines can’t build a mattress that lasts. Next up: how those wires become the familiar hourglass-shaped coils that power traditional mattresses.

How Do Bonnell Spring Machines Work?

The workhorse of the spring world.

Bonnell spring machines produce hourglass-shaped coils, coiled from wire and knotted at each end, then laced into units. These machines are widely used due to their simplicity and high-speed output.

Key Features:

- Wire fed, coiled, and knotted

- Springs automatically assembled into rows

- Ideal for high-volume production

Applications:

- Budget-friendly mattresses

- Entry-level exports

- High-rotation hotel and dorm markets

Why Choose It?

Fast output, low cost, and long-proven performance.

What Makes Pocket Spring Machines So Specialized?

Precision engineering for high-end comfort.

Pocket spring machines coil wire, compress the spring, insert it into fabric sleeves, and thermally or ultrasonically seal the pockets. Springs are then glued or sewn together in rows.

Key Features:

- Independent coil movement = no motion transfer

- Customizable spring count, height, and gauge

- Multi-zone layouts programmable

What Sets Apart a 200 Springs/Min Pocket Spring Machine?

Engineered for serious volume.

A pocket spring machine rated for 200 springs per minute isn’t just fast—it’s designed for seamless, finely tuned throughput. Here’s what makes it stand out:

Key Capabilities:

- High-speed coil winding and seamless pocket insertion keep production lines moving without bottlenecks.

- Automated compression and cutting maintain uniform spring tension and length, crucial for premium comfort.

- Precision-driven fabric feeding, sealing, and cutting systems minimize material waste and ensure consistent welds, whether thermal or ultrasonic.

Production Advantages:

- Rapid changeovers for different spring heights and gauges, so you can switch between product specs with minimal downtime.

- Integrated quality control sensors spot alignment and sealing errors instantly, reducing rejects and boosting yield.

- Modular layouts fit easily into larger automated mattress assembly lines—think Hilding Anders or Serta-level scalability.

Best For:

- High-volume runs of luxury mattresses

- Multi-zone and custom spring layouts

- Manufacturers seeking both speed and precision

With these machines, you’re poised to deliver tailored comfort at scale—without missing a beat.

What Are the Production Speeds Offered by Pocket Spring Coiling Machines?

Choose your pace—whether you’re scaling up or dialing in precision.

Modern pocket spring coiling machines are available in a range of output speeds to match your production targets:

- Up to 200 springs per minute: Ideal for large-scale, high-speed manufacturing lines where maximum throughput is critical.

- Around 160 springs per minute (double wire models): Strikes a balance between speed and flexibility, allowing simultaneous coiling of two wire types for diverse builds.

- Approximately 130 springs per minute: Suited for mid-size operations or when customization, frequent changeovers, or specialty spring configurations are a priority.

This versatility ensures there’s a fit for growth-focused factories, specialty workshops, and everything in between.

What Sets a 130 Springs/Minute Pocket Spring Machine Apart?

Production at high speed with precision quality.

A pocket spring machine rated for 130 springs per minute is engineered for manufacturers who demand both speed and craftsmanship. This level of performance ensures you can fulfill large orders without sacrificing consistency or detail.

What to Expect:

- Rapid coiling, compressing, and insertion of individual springs into fabric pockets

- Precise heat or ultrasonic sealing for each pocket, even at maximum speed

- Programmable to adjust spring height, gauge, and distribution for various mattress types

- Efficient glue or stitch assembly of spring rows for streamlined final unit construction

Ideal For:

- Factories scaling up luxury, hybrid, or custom mattresses

- Brands competing with the output levels of Leggett & Platt, HSM, or Spühl

- Manufacturers serving high-turnover retail or export markets

Such machines make premium, highly customized spring systems a reality—without slowing your line down.

Applications:

- Hybrid mattresses

- Orthopedic and pressure-relief beds

- Premium export products

Why Choose It?

They sell better—and at higher margins.

Automatic vs. Semi-Automatic: Choosing the Right Pocket Spring Assembly Solution

Efficiency meets flexibility.

Automatic pocket spring assembly machines are the heavy lifters of mattress production. They streamline the process—connecting, aligning, and joining spring rows—at dizzying speeds with minimal supervision. This means you can crank out large batches while enjoying precise, repeatable quality. For example, German brands like Spühl or HSM set the industry gold standard, rolling out thousands of springs with barely a coffee break.

In contrast, semi-automatic machines offer a sweet spot for nimble operations. They require a bit more operator input—think manual adjustments or feeding between steps—but reward you with greater flexibility and a friendlier price tag. This makes them ideal for custom runs, prototyping, or smaller production spaces where agility matters.

Bottom line:

- Automatic machines: Best for high-volume, standardized output.

- Semi-automatic machines: Optimal for versatility, small batches, and budget-minded production.

Choose based on your workflow—whether it’s speed and scale or craftsmanship and control.

Advantages of Dual Line Pocket Spring Machines

Twice the output, zero compromise.

Dual line pocket spring machines raise the bar by allowing manufacturers to produce two rows of springs simultaneously—slashing production time in half without trading precision for speed.

Benefits include:

- Streamlined output: Double the springs, faster mattress builds

- Maintained quality: Each coil remains consistently sealed and aligned

- Synchronized perfection: Both rows adhere to exacting standards for comfort and support

With these machines on your factory floor, scaling up production for growing demand becomes a reality, all while maintaining the premium craftsmanship that keeps your mattresses ahead of the pack.

How Do Single Line Pocket Spring Machines Boost Efficiency?

Productivity, simplified.

Single line pocket spring machines roll out an uninterrupted stream of coiled springs, automatically wrapping each in its own fabric sleeve before sealing and cutting to precise specs—all in one fluid motion.

Why does this matter for manufacturers?

- Cuts down on production steps and manual handling

- Reduces labor needs and error risks

- Delivers consistent spring quality, batch after batch

Whether you’re outfitting a high-volume factory or fine-tuning a boutique line, these machines keep operations humming. More output, less downtime—without sacrificing any of that signature luxury feel.

Why Is Pocket Spring Assembly So Critical?

It’s all in the details. The assembly of pocket springs is where mattress innovation really happens—dictating support, durability, and comfort in every finished product.

Here’s why this process is central:

- Pocket springs can be arranged in limitless layouts—from single rows to advanced multi-zone grids—tailoring support exactly where it’s needed.

- The quality of coiling, pocketing, and precise assembly ensures individual springs respond to movement, boosting sleep quality and longevity.

- This versatility allows manufacturers to cater to trends—think orthopedic mattresses, hybrid constructions, or specialty export pieces—giving them a sharp edge over run-of-the-mill offerings.

What Role Does a Pocket Spring Cutting Machine Play in Production?

Cutting to precision—and speed.

A pocket spring cutting machine trims fabric-encased spring rows to the exact length needed for mattress assembly. After the springs are coiled, inserted into fabric pockets, and sealed, the cutting machine automatically slices each spring string to the mattress’s specified width or zone requirements.

Key Features:

- High-speed, automated length adjustment

- Crisp, fray-free cuts for clean assembly

- Seamless integration with pocket spring production lines

Why It Matters:

Accurate cutting means every mattress core is consistent—no guesswork, no wasted materials—helping streamline downstream gluing or sewing processes.

Simply put, mastering pocket spring assembly isn’t just another step; it’s the secret behind mattresses that command attention in any showroom—and often, higher price tags.

Micro Pocket Spring Machines for Sofas

Tailored engineering for upholstered comfort.

Micro pocket spring machines craft smaller-diameter coils, perfectly suited for sofa cushions and seating. The process mirrors mattress construction: coiling fine wire, encasing each spring in a soft fabric pouch, and sealing every pocket securely. These compact springs are then joined in flexible grids—ready to be tucked into sofa seats and backrests.

Distinct Advantages:

- Enhanced ergonomic support without bulky foam

- Greater flexibility in sofa design and dimensions

- Improved airflow for cooler, longer-lasting seating

Industry Applications:

- High-end sectional sofas

- Recliners and luxury seating collections

- Premium export-ready furniture

Why Use Micro Pocket Springs?

Sofas built with these springs deliver superior comfort and long-term shape retention—a win for demanding buyers and boutique furniture retailers alike.

Double Wire, High-Speed Pocket Spring Performance

Efficiency meets innovation at 160 springs per minute.

A double wire pocket spring machine cranks out up to 160 springs every minute—serious speed, without sacrificing accuracy. By using dual wire feeds, it creates paired coils simultaneously, doubling productivity and ensuring every spring is consistent.

Standout Features:

- Dual wire feeding for twice the output

- Automated coil forming, pocketing, and cutting

- Adjustable spring dimensions for flexible production

- Thermal or ultrasonic sealing for fabric pockets

Ideal For:

- Large-scale mattress factories with ambitious throughput

- Meeting surge orders or export deadlines

- Manufacturers prioritizing both volume and precision

Why does this matter?

More springs, less downtime—which means meeting demand, maximizing efficiency, and locking in top-tier sales.

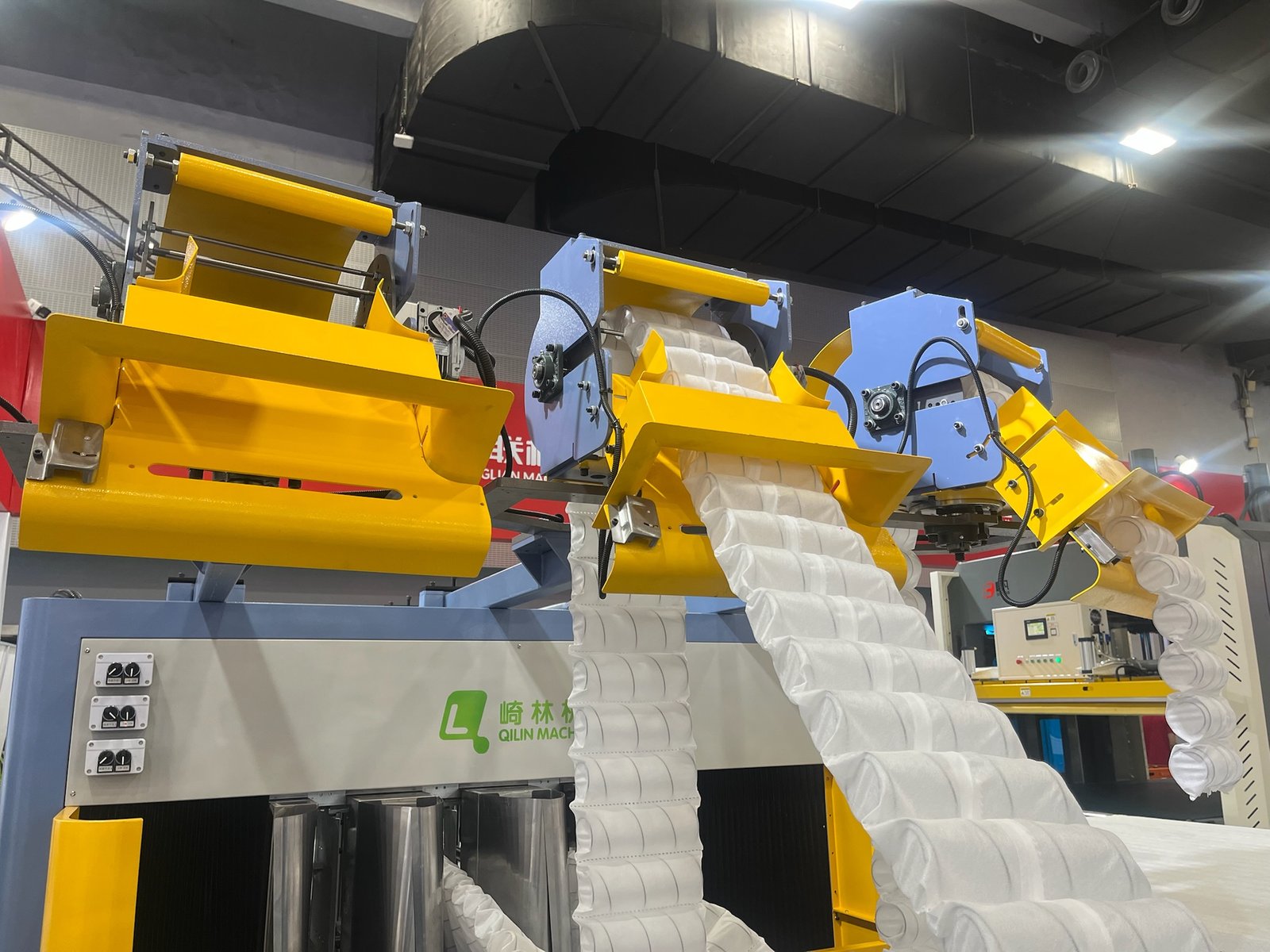

See the Machine in Action

Curious how this intricate process unfolds on the factory floor? Watch a working demonstration to see pocket spring machines in action—coiling, wrapping, sealing, and lining up precise rows of springs.

Watch the demonstration on YouTube to get a real feel for the technology and craftsmanship that goes into every pocket spring unit.

How Do Continuous Coil Spring Machines Improve Efficiency?

One wire. Hundreds of springs.

Continuous coil machines form springs from a single wire strand that loops through and connects each coil. It’s the most material-efficient design.

Key Features:

- Lower scrap wire

- Minimal raw material joints = high strength

- Faster production cycle vs. pocket springs

Applications:

- Value mattresses

- Rental or institutional beds

- Markets with price sensitivity

Why Choose It?

Low input costs, quick throughput, solid support.

Where Do Offset Spring Machines Fit In?

The sweet spot between bounce and body contour.

Offset machines form squared-off coils, typically joined with hinging helical wires. This configuration creates a flexible, supportive feel.

Key Features:

- Reduces roll-together sensation

- Offers targeted lumbar and edge support

- Often combined with reinforced frames

Applications:

- Adjustable beds

- Zoned orthopedic mattresses

- Mid to high-end domestic lines

Why Choose It?

Blends the resilience of Bonnell with the contouring of pocket springs.

Which Machines Produce Sofa Zig-Zag Springs?

When it comes to furniture comfort, zig-zag (or sinuous) springs are the unsung heroes—especially in sofas and sectionals.

Specialized zig-zag spring machines are engineered to form heavy-gauge wire into the signature S-shaped curves, cut to custom lengths, and notch or punch ends automatically for fast installation. These setups deliver consistency and speed for both low- and high-volume upholstery production.

Key Features:

- Rapid wire bending into precise S-curves

- Automated measurement and cutting for exact fit

- End forming options (such as loops, clips, or hooks)

- Adaptability for different wire gauges and spring heights

Applications:

- Sofa and sectional seating

- Recliners and accent chairs

- Automotive seats

Why Choose It?

Effortless consistency, time savings, and sturdy springs built to handle years of movie marathons—or showroom tumbles from excited shoppers.

What Role Do Computerized Spring Machines Play?

Custom production? It starts here.

These machines use touchscreens and PLCs to control tension, coil count, pitch, and wire diameter—often with AI-based auto-calibration.

Key Features:

- Program batch recipes (e.g., 3-zone spring units)

- Auto-adjust tension per coil

- Store multiple SKU settings

- Integrate with cutting and gluing stations

Applications:

- Smart factory production lines

- Mixed product plants (multiple mattress types)

- Export compliance needs (EU/US specs)

Why Choose It?

Scalable flexibility with higher QC accuracy.

How Do Automation and Integration Affect Production?

It’s not just about springs—it’s about speed, precision, and coordination.

Spring machines today are built for integration. They connect to conveyor belts, glue stations, and mattress assembling lines.

Integrated System Benefits:

- Faster line speeds = higher daily output

- Fewer workers needed

- Auto reject + auto stacking = lower error rates

You’ll also see lower wire waste, tighter quality control, and real-time production tracking.

What Are Your Options: Fully Automatic vs. Semi-Automatic Pocket Spring Assembly?

Assembly lines, streamlined to fit your volume.

If you’re considering pocket spring production, you’ll need to decide between fully automatic and semi-automatic assembly systems. Here’s how they stack up:

Fully Automatic Assembly Lines:

These systems do it all—feeding, coiling, pocketing, gluing, and stacking—at the press of a button. Output rivals the best from Duerkopp Adler or Spuhl. Think maximum throughput and minimal manual labor:

- High-speed, continuous operation (think 120+ springs/minute)

- Robotic alignment and gluing

- Real-time monitoring and fault detection

- Ideal for mass production and plants with lean staffing

Semi-Automatic Assembly Lines:

These setups combine automation with manual placement or QC. Great for businesses scaling up or looking for flexibility:

- Some steps (glue, bag feed, stacking) may require operator input

- Lower capital investment vs. Full automation

- Easier maintenance—great for modular plants or custom runs

- Responsive when you need quick changeovers or shorter runs

The choice comes down to scale, budget, and the level of control you want over every spring unit. High-speed? Go fully auto. Need agility? Semi-auto gives you room to pivot.

What Other Essential Machines Are Needed Beyond Springs?

One machine doesn’t make a mattress—there’s an entire squad behind the scenes. Beyond spring coiling, you’ll want to round out your line with equipment that handles foam, quilting, and packing with equal efficiency.

Core Mattress Machinery Includes:

- Foam Processing Machines: Think high-precision foam cutting tables, automated carousels, and splitters for memory foam or latex layers. These beauties let you customize contours, cut complex shapes, or slice super-thin toppers—all in one workflow.

- Quilting Machines: Computerized, multi-needle quilting stations stitch together everything from intricate Euro-top patterns to utilitarian panel quilting—like a Bernina on rocket fuel. Popular formats include chain-stitch and lock-stitch, with programmable patterns for your signature look.

- Panel and Border Cutters: CNC-controlled machines trim panels and cut borders to size. Crisp edges and accurate dimensions? No sweat—your production line runs faster, and manual error plummets.

- Sewing and Flanging Machines: Automated flangers and border sewing systems attach side panels, flanges, and handles with seamless speed. Perfect edges and tight seams, minus the “oops” factor.

- Tape Edge Machines: High-speed, chain-stitch, or lock-stitch units wrap mattresses in a clean, durable tape edge—a finishing touch that buyers notice. Consistency counts, especially for retail-facing finishes.

- Packing and Wrapping Machines: Automatic roll-packers and compression baggers get beds ready for e-commerce or efficient shipping. Minimal manual labor, maximum space savings.

These supporting machines turn mattress production into a true assembly line—each step automated, every piece precisely in sync.

Quality Control and Durability: What’s Built In?

Modern machines test spring tension, load, and consistency as they run. Sensors flag off-tolerance springs for rejection before they enter the mattress.

Key checks include:

- Tensile strength

- Coil height uniformity

- Weld/bond integrity

Quality assurance = fewer complaints, fewer returns, more repeat buyers.

Conclusion

Whether you’re producing budget innersprings or high-end hybrid cores, your spring machine is the backbone of your mattress line. Choose based on spring type, quality targets, and production scale—because every machine shapes not just coils, but your bottom line.