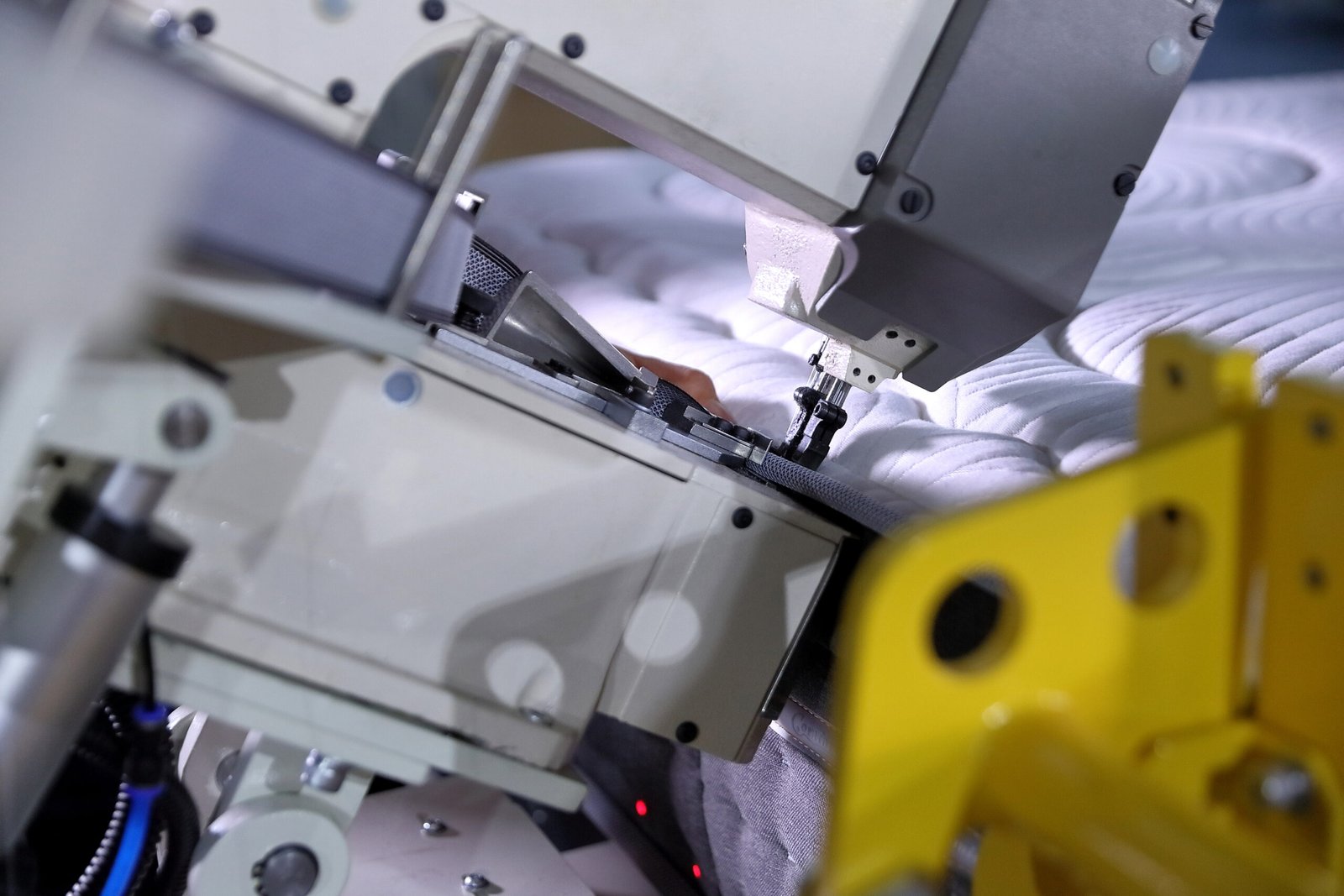

How to prevent the needle of a mattress sewing machine from breaking?

A broken needle in a mattress sewing machine can lead to damaged materials, production delays, and even machine downtime. To maintain smooth operations and high-quality stitching, it is essential to identify and prevent common causes of needle breakage.

What Causes Needle Breakage in a Mattress Sewing Machine?

1. Incorrect Needle Type and Size

Leading Challenge:

Using the wrong needle size or type increases the risk of breakage when sewing through thick mattress fabrics and heavy layers.

Solution:

- Choose a heavy-duty needle suited for mattress materials, such as size 16/100 or 18/110 for thick fabrics.

- Use ballpoint needles for knitted or stretch fabrics to avoid snags.

- Consult the machine manual to ensure compatibility between the needle, thread, and fabric type.

2. Worn or Dull Needles

Leading Challenge:

Over time, needles become dull, bent, or worn, leading to uneven stitching, skipped stitches, and needle breakage.

Solution:

- Replace the needle every 6 to 10 hours of use, especially when working with thicker or abrasive materials.

- Inspect the needle for bends, burrs, or damage before starting a new sewing cycle.

- Use high-quality industrial needles to ensure durability and precision.

3. Improper Needle Installation

Leading Challenge:

A loose or misaligned needle increases pressure on the needle shaft, causing it to snap.

Solution:

- Ensure the needle is fully inserted into the holder and tightened securely.

- The flat side of the needle should face the correct direction according to the machine specifications.

- Regularly check the needle clamp to prevent vibrations that may loosen the needle.

4. Excessive Thread Tension

Leading Challenge:

Incorrect thread tension puts extra strain on the needle, leading to bending or breakage.

Solution:

- Adjust both upper and lower thread tension based on fabric thickness.

- Test stitch on scrap fabric to ensure proper balance before sewing the final mattress.

- Use high-quality thread to reduce friction and tension issues.

5. High Sewing Speed

Leading Challenge:

Running the machine too fast on thick materials can cause sudden needle impact, leading to breakage.

Solution:

- Lower the sewing speed when working with multiple layers or tough fabrics.

- Machines with variable speed control allow operators to adjust the speed based on fabric type.

- Avoid sudden speed changes to maintain consistent stitching.

6. Machine Misalignment or Timing Issues

Leading Challenge:

If the needle and hook timing are not properly aligned, the needle can hit the bobbin case or presser foot, causing it to break.

Solution:

- Regularly check the timing mechanism to ensure the needle enters the fabric at the correct point.

- If experiencing frequent needle breakage, consult a technician for timing adjustments.

- Ensure the bobbin case is properly positioned to avoid obstructions.

7. Fabric Handling Issues

Leading Challenge:

Pulling or forcing fabric through the machine causes uneven tension, which can bend or break the needle.

Solution:

- Guide the fabric gently without excessive pulling or stretching.

- Use stabilizers for slippery materials to improve feeding.

- Adjust the presser foot pressure to prevent the fabric from moving unpredictably.

Best Practices to Prevent Needle Breakage

| Preventive Measure | Benefits |

|---|---|

| Use the correct needle size/type | Reduces breakage by ensuring compatibility with fabric and thread. |

| Replace needles regularly | Prevents dullness and bending, maintaining stitching quality. |

| Proper needle installation | Ensures the needle is secure and aligned correctly. |

| Adjust thread tension | Prevents excessive strain on the needle. |

| Control sewing speed | Reduces impact force on the needle when sewing thick layers. |

| Check machine alignment and timing | Prevents the needle from striking machine components. |

| Handle fabric smoothly | Prevents tension inconsistencies that cause bending or breakage. |

Conclusion

Preventing needle breakage in a mattress sewing machine requires using the correct needle, maintaining proper installation, adjusting speed, and ensuring accurate thread tension. By following these preventive measures, manufacturers can reduce machine downtime, improve efficiency, and maintain high-quality mattress production.