How Does a Mattress Packaging Machine Ensure Consistent Packaging Quality?

Ensuring consistent packaging quality in mattress manufacturing is essential for maintaining product integrity, reducing damage, and enhancing customer satisfaction. Mattress packaging machines incorporate advanced automation, control systems, and quality control mechanisms to standardize packaging processes and minimize errors. In this article, we will explore the key elements that contribute to consistent packaging quality in mattress production.

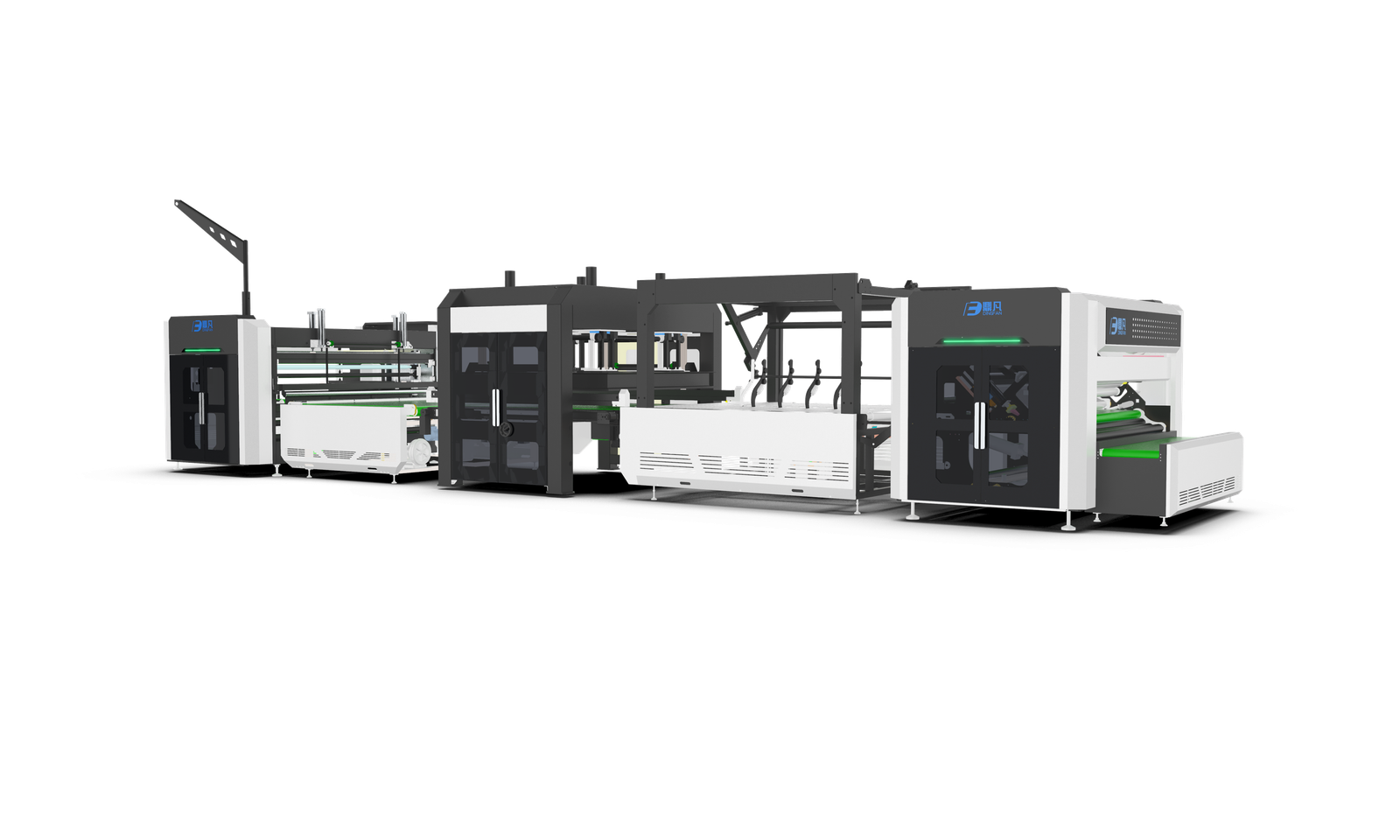

Automation and Standardization in Mattress Packaging

Automation: Increasing Efficiency and Accuracy

- Higher Production Speed: Automated packaging machines significantly increase speed, enabling manufacturers to package hundreds of mattresses per hour.

- Reduced Labor Dependency: By minimizing manual intervention, automation reduces human errors and labor costs while improving efficiency.

- Consistent Process Execution: Automated packaging follows pre-programmed settings, ensuring uniform wrapping, compression, and sealing for every mattress.

Standardization: Ensuring Uniform Packaging Quality

- Uniform Wrapping & Sealing: Standardized packaging settings ensure that every mattress is sealed securely, preventing variations in size, compression, and protection.

- Regulatory Compliance: Consistent packaging helps manufacturers comply with industry regulations for labeling, safety, and packaging material usage.

Advanced Control Systems for Precision Packaging

PLC and Touch Screen Controls

- Precision Control: PLC (Programmable Logic Controller) systems ensure accurate compression, wrapping, and sealing settings based on mattress dimensions.

- Customizable Parameters: Operators can adjust settings like compression force, roll diameter, and sealing time, optimizing packaging for different mattress types.

- Real-Time Monitoring: PLCs allow continuous tracking of machine performance, identifying inefficiencies and making immediate adjustments.

Touch Screen Operation for Easy Management

- User-Friendly Interface: Modern machines feature intuitive touch screens that simplify operation and reduce training time for workers.

- Multi-Language Support: Some machines offer multi-lingual interfaces, making them accessible for international operations.

- Quick Troubleshooting: Operators can receive error notifications and adjust machine settings in real time, preventing quality inconsistencies.

Photoelectric Positioning for Precise Packaging

How Photoelectric Sensors Improve Accuracy

- Exact Alignment: Photoelectric sensors detect mattress edges, ensuring precise positioning during compression and sealing.

- Minimized Material Waste: By aligning film placement correctly, sensors reduce excess material usage, improving cost efficiency.

- Error Detection: If a mattress is misaligned, the system automatically adjusts before sealing, preventing defects.

High-Definition Dynamic Display for Real-Time Monitoring

Advantages of HD Displays in Packaging Machines

- Live Process Visualization: Operators can monitor each stage of the packaging process in real-time, improving control.

- Instant Quality Feedback: If irregularities occur, the machine displays alerts, allowing for quick corrections.

- Data Storage & Analysis: Machines log historical data, helping manufacturers track trends, identify recurring issues, and optimize packaging performance.

Quality Control Measures in Mattress Packaging

Automated Inspection Systems

- Defect Detection: Automated camera-based inspections detect wrapping errors, misalignment, or improper sealing.

- Consistent Standards: The system ensures that all mattresses meet the same quality benchmarks, reducing returns and defects.

Predictive Maintenance for Machine Reliability

- Proactive Repairs: Sensors predict component wear and tear, preventing unexpected machine breakdowns.

- Continuous Operation: Regular self-diagnosis minimizes downtime and ensures consistent packaging quality.

Final Inspection Before Shipment

- Visual & Functional Testing: Inspectors check for sealing defects, compression errors, and wrapping issues.

- Compliance Verification: Each mattress is labeled with batch details and quality certification, ensuring compliance with regulations.

Conclusion

Mattress packaging machines ensure consistent quality by integrating automation, advanced control systems, real-time monitoring, and predictive maintenance. Features like PLC control, photoelectric positioning, and high-definition displays enhance precision and efficiency, while quality control measures guarantee that each mattress meets industry standards. By adopting these technologies, manufacturers reduce waste, improve efficiency, and deliver high-quality packaged mattresses to consumers.

📩 Contact us now to learn more! 😊

📞 WhatsApp: +86 15220512074

📧 Email: zhongliantec@gmail.com