What Types of Mattress Spring Machines Are Available on the Market?

What Types of Mattress Spring Machi

Our Mattress Border Sewing Machines offer advanced, efficient solutions designed for mattress manufacturing. From automatic tape edge machines to semi-automatic border sewing machines.

We are proud to partner with clients worldwide, providing efficient, reliable, and cost-effective mattress and furniture packaging solutions.

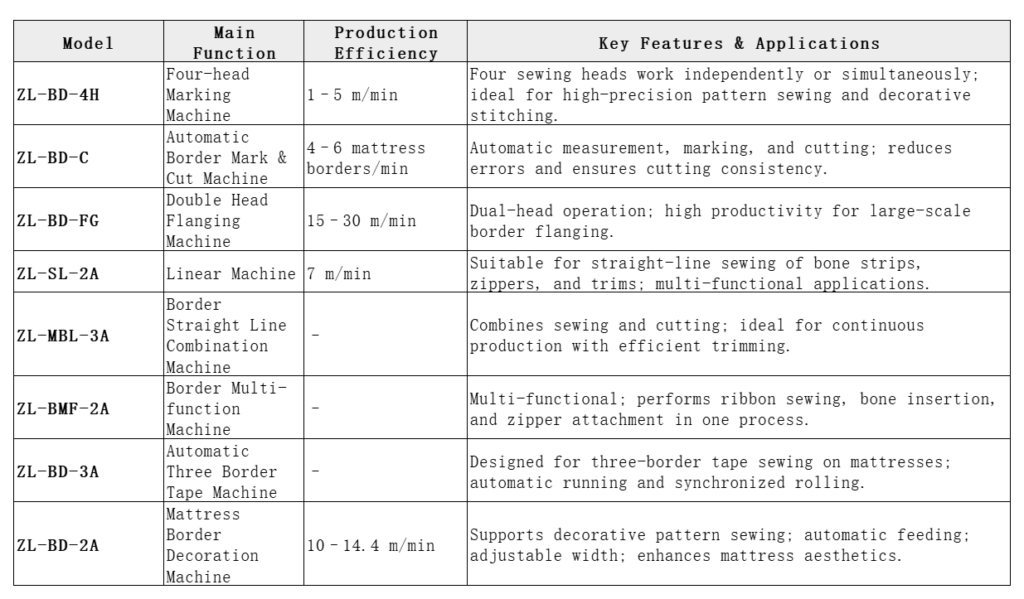

Our border sewing machine series offers a comprehensive range of solutions for mattress border processing.

ZL-BD-4H, ZL-BD-2A:decorative stitching and pattern sewing

ZL-BD-C:automated border marking and cutting

ZL-BD-FG:high-volume flanging production

ZL-MBL-3A, ZL-BMF-2A:integrated sewing and cutting solutions

ZL-BD-3A:mattress three-border tape sewing and visual enhancement

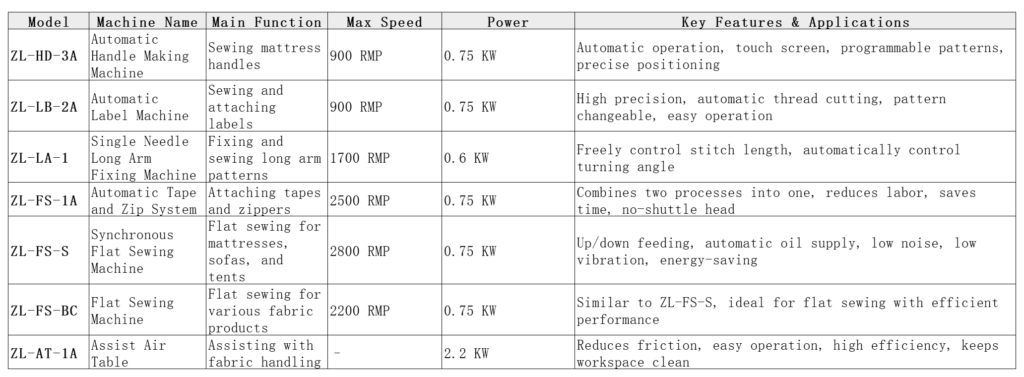

Handle & label sewing: ZL-HD-3A, ZL-LB-2A

Tape & zipper application: ZL-FS-1A

Flat sewing applications: ZL-FS-S (high speed), ZL-FS-BC (standard speed) Complex pattern sewing: ZL-LA-1

Fabric handling support: ZL-AT-1A

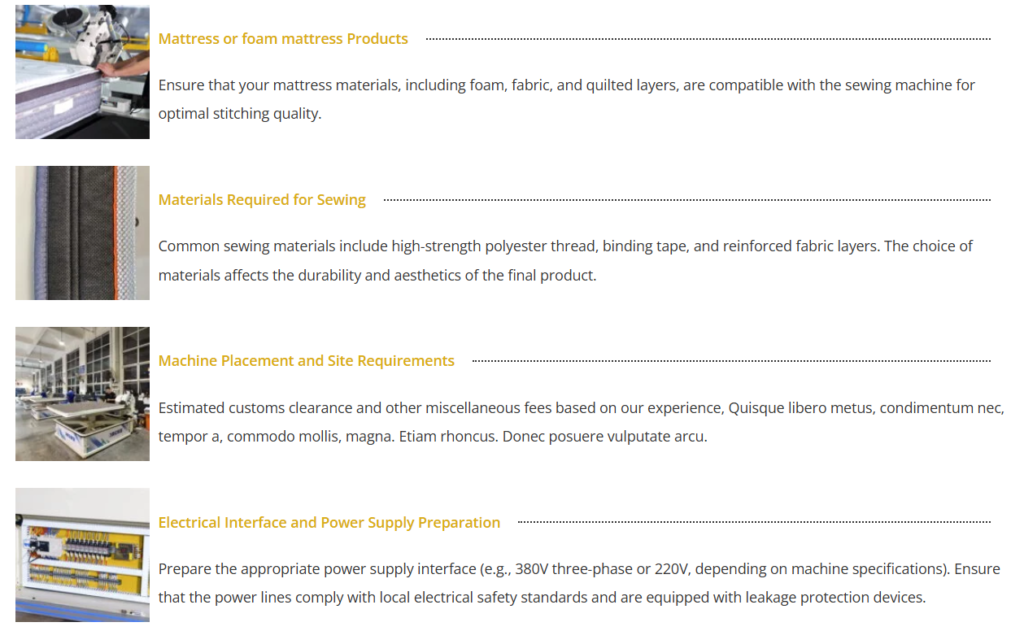

To ensure smooth installation and efficient operation of the mattress sewing machine, please prepare the following materials and installation environment in advance.

Ensure that your mattress materials, including foam, fabric, and quilted layers, are compatible with the sewing machine for optimal stitching quality.

Common sewing materials include high-strength polyester thread, binding tape, and reinforced fabric layers. The choice of materials affects the durability and aesthetics of the final product.

Estimated customs clearance and other miscellaneous fees based on our experience, Quisque libero metus, condimentum nec, tempor a, commodo mollis, magna. Etiam rhoncus. Donec posuere vulputate arcu.

Prepare the appropriate power supply interface (e.g., 380V three-phase or 220V, depending on machine specifications). Ensure that the power lines comply with local electrical safety standards and are equipped with leakage protection devices.

Please note that the actual timeline may vary depending on site conditions, preparation adequacy, and logistics. Below is a typical process outline after receiving the mattress sewing machine.

What Types of Mattress Spring Machi

How Much Production Capacity Can Ma

Can One Machine Produce Different T

WhatsApp us