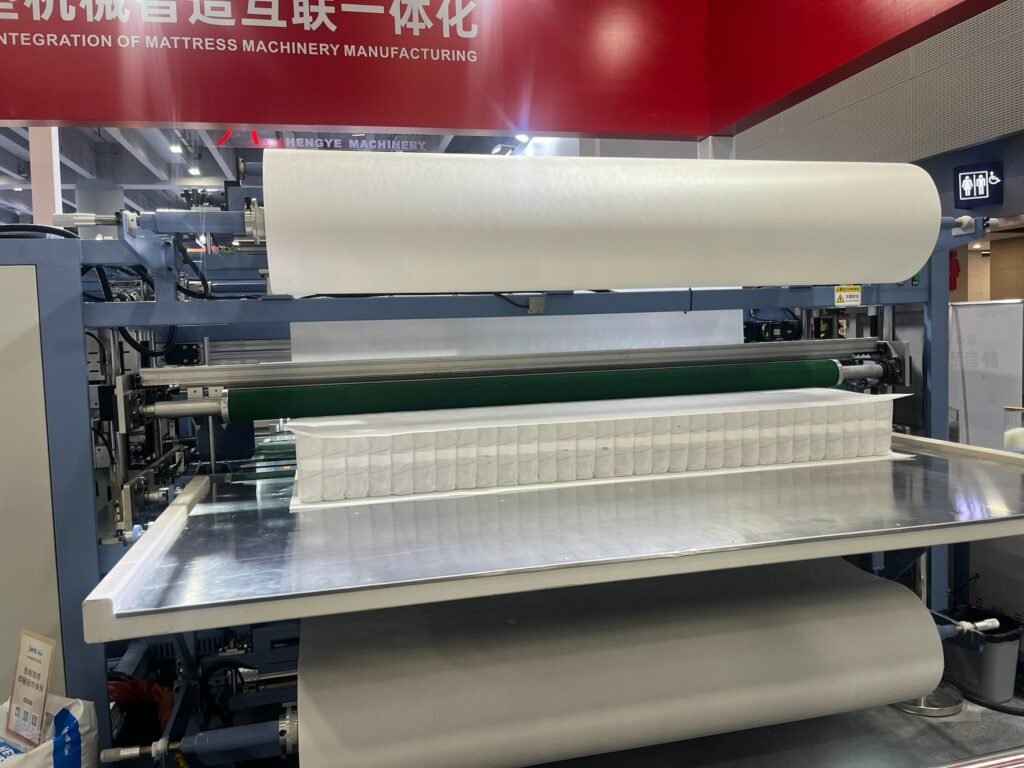

- 1. Adapt to cylindrical and barrel shape springs

- 2. Parallel or nest gluing are available

- 3. The non-woven feeder system,save material and labor

- 4. Multiple fault detecting device, effectively reduce the wastage

- 5. Full automatic production line, save labor and cost

- 6. Special protective device

- 7. Increase the diversion conveyor belt to effectively improve production efficiency.

- Remark: Can use 1pc, 2pcs or 3pcs pocket spring coiling machines according to different requirements.

Detail For Mattress Spring Adhesive Machine

in the production line of pocket spring mattresses or pocket spring sofas. It can select and cut continuous bag spring materials for bonding. The fully automatic pocket spring assembly machine is currently a popular spring bed net bonding equipment in the industry. This machine is mainly used

production, but also features a unique splitter conveyor belt, effectively improving production efficiency. It is an essential specialized equipment for The ZJ8L fully automatic pocket spring assembly machine not only has the advantages of easy operation, stable production, and fully automaticproducing pocket spring mattresses or pocket spring sofas.

Application Of Mattress Spring Adhesive Machine

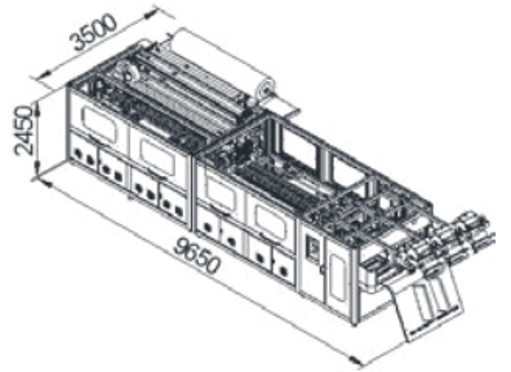

| Machine Model | ZJ8L Fully Automatic Gluing Machine | |

|---|---|---|

| Efficiency | About 2 minutes per pocket spring net | |

| Air Requirement | 0.4 m³/min, 0.6 MPa | |

| Power Requirement | 3P 380V 50Hz (customizable) | |

| Working Temperature | 0℃ – 35℃ | |

| Total Power | 20 kW | |

| Gross Weight | About 8000 kg | |

| Machine Size (L×W×H) | 9650 × 3500 × 2450 mm | |

| Material Specifications | ||

| Pocket Spring Height | 100–300 mm (can be customized) | |

| Spring Central Diameter | φ45–80 mm | |

| Non-woven Fabric Thickness | 70–100 g/m² | |

| Non-woven Fabric Width | 450–2200 mm | |

| Inner Diameter of Non-woven | ≥ 60 mm | |

| Outer Diameter of Non-woven | ≤ 500 mm | |