What Are the Power Requirements for Mattress Spring Machinery?

What Are the Power Requirements for Mattress Spring Machinery?

Introduction

Mattress spring machinery is essential for producing high-quality springs that form the core of mattresses, ensuring comfort and durability. Understanding the power requirements of these machines is crucial for manufacturers seeking to optimize production efficiency, reduce operational costs, and maintain safety standards. This article explores various aspects of the power needs of mattress spring machinery, including types of machinery, power sources, electrical requirements, energy consumption, safety considerations, power management, installation needs, environmental impacts, and future trends.

Introduction to Mattress Spring Machinery

Mattress spring machinery is designed to manufacture the springs that provide essential support, durability, and comfort in a mattress. The most common types of springs used in mattress production are:

- Bonnell Springs: Hourglass-shaped and interconnected, providing firm support.

- Pocket Springs: Individually wrapped coils, offering better motion isolation and tailored support.

- Continuous Coils: Formed from a single piece of wire, providing a uniform support structure.

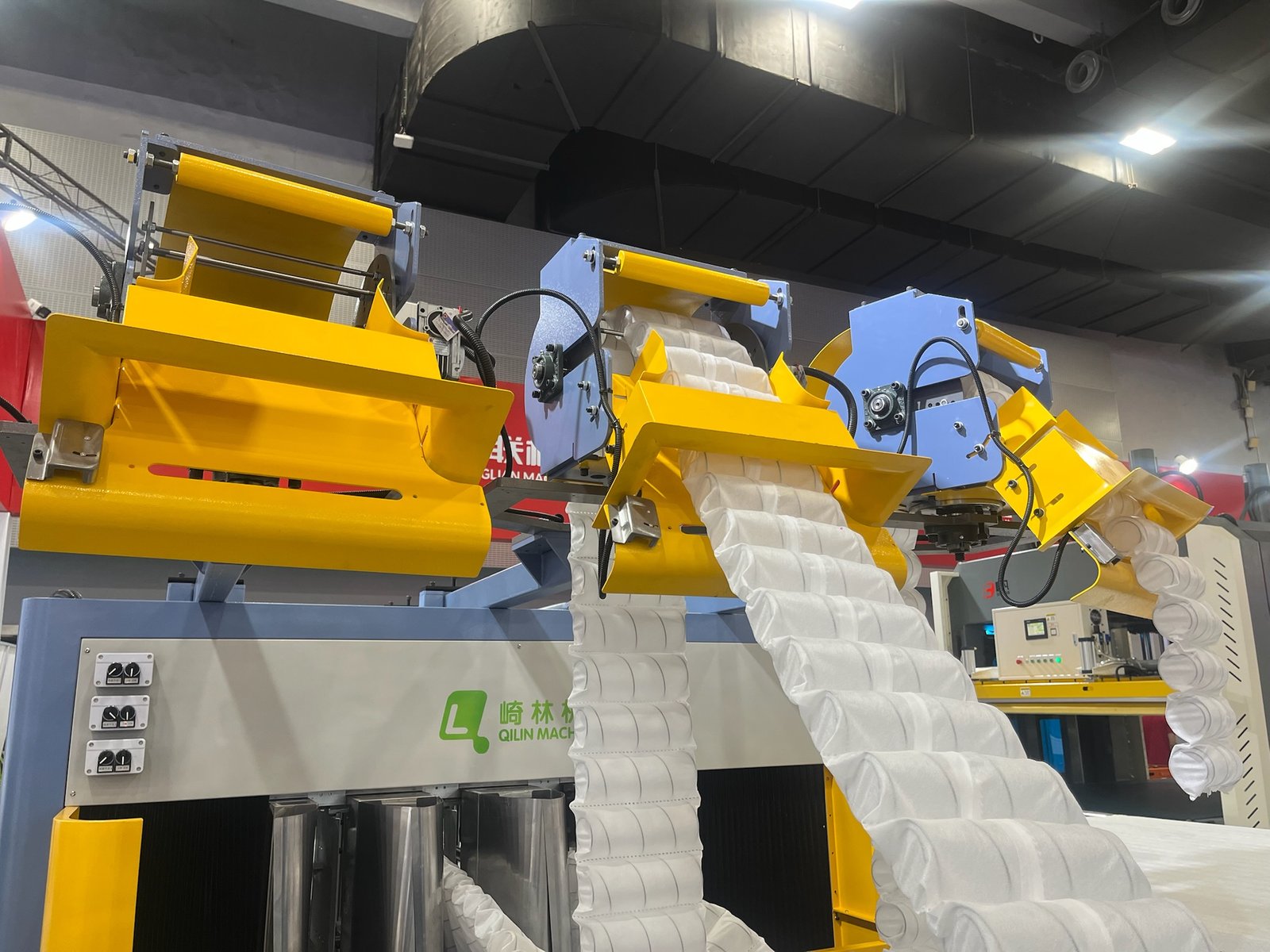

To produce these springs, specialized machinery is used, including coiling machines for shaping the springs, assembly machines for connecting them into a mattress core, and sewing machines for stitching fabric pockets for pocket springs. Each machine plays a vital role in ensuring that the springs meet the necessary standards for performance.

Types of Mattress Spring Machinery

The production of mattress springs requires various machines, each with its specific function:

- Coiling Machines: These shape the wire into different spring types, such as Bonnell, pocket, and continuous coils. The settings and configurations of these machines determine which type of spring is produced.

- Assembly Machines: These connect the springs to form the mattress core. For Bonnell and continuous coils, this involves interconnecting the springs, while for pocket springs, it includes placing the springs into fabric pockets.

- Sewing Machines: These stitch the fabric pockets for pocket springs, securing them so that the springs stay in place.

- Auxiliary Machines: Other machines, such as cutting and gluing machines, may be required depending on the specific design of the mattress.

Each machine requires specific power sources and electrical configurations to operate efficiently.

Power Sources for Mattress Spring Machinery

Mattress spring machinery can be powered by different sources, including electrical, pneumatic, and hydraulic systems:

- Electrical Power: The most common power source, electrical systems provide consistent and reliable energy, ideal for precision tasks such as spring coiling and assembly. Electrical systems are generally efficient and easy to control.

- Pneumatic Power: Pneumatic systems use compressed air to power machinery. These are often used for tasks requiring quick, repetitive motions, like sewing and cutting. Pneumatic systems are less expensive to maintain but may not be as efficient and require a reliable air supply.

- Hydraulic Power: Hydraulic systems use fluid pressure to power machines. They are suitable for tasks that require high force and precision, such as spring forming and assembly. While hydraulic systems are powerful and efficient, they are more complex and costly to maintain compared to electrical or pneumatic systems.

Manufacturers must carefully choose the power source based on machine requirements, production volume, and budget considerations.

Electrical Power Requirements

The electrical power requirements for mattress spring machinery depend on the type and size of the machine:

- Coiling Machines: These machines typically require substantial electrical power, as they need precision and force to form the springs. A three-phase power supply is commonly required, with voltages ranging from 220V to 480V. Current requirements may range from 10A to 50A or more, depending on the machine’s size and speed.

- Assembly Machines: These machines, which connect the springs, also require significant power, particularly for tasks such as welding or gluing. They usually have similar voltage and current specifications to coiling machines, often requiring three-phase power.

- Sewing Machines: These machines, used for pocket spring production, typically have lower power requirements. They often run on single-phase power with voltages between 110V and 240V, with current ranging from 5A to 20A.

It is essential to comply with local electrical standards, including proper grounding, circuit protection, and emergency stop mechanisms, to ensure the safe and reliable operation of machinery.

Energy Consumption and Efficiency

Energy consumption is a key factor in mattress spring machinery. High energy consumption can increase operational costs and environmental impact. The energy efficiency of these machines can be influenced by factors such as:

- Age and Condition of the Equipment: Older machines may consume more energy due to wear and tear, while newer, more efficient models can reduce energy usage.

- Type of Power Source: Electrical machines are generally more energy-efficient compared to pneumatic or hydraulic systems, though they may have higher operating costs.

- Maintenance and Components: Regular maintenance ensures that machines operate efficiently. Implementing energy-saving technologies, such as Variable Frequency Drives (VFDs) and energy-efficient motors, can further reduce energy consumption.

Manufacturers should regularly monitor energy consumption and implement strategies to improve energy efficiency, such as scheduling maintenance, upgrading components, or optimizing production schedules to reduce downtime.

Safety Considerations

When working with power systems for mattress spring machinery, safety is critical to protect workers and equipment. Essential safety features include:

- Emergency Stop Mechanisms: These allow operators to quickly shut down the machinery in case of an emergency, preventing accidents and minimizing damage.

- Proper Grounding: Ensures that electrical systems are safe, reducing the risk of electrical shock.

- Overload Protection: Prevents machinery from operating beyond its capacity, which helps avoid damage and ensures safe operation.

Manufacturers must adhere to safety standards and regulations to ensure that machinery is safe for operators and efficient in its performance.

Power Management and Control Systems

Power management and control systems are vital for regulating the power supply to mattress spring machinery. One common control system is the Programmable Logic Controller (PLC), which automates and regulates various aspects of the production process. These systems allow operators to:

- Monitor power usage in real-time.

- Adjust settings for optimal energy consumption.

- Maintain a consistent production output with minimal energy waste.

By implementing robust power management and control systems, manufacturers can ensure the machinery operates at peak efficiency while minimizing energy usage and reducing costs.

Installation and Environmental Impact

Installing mattress spring machinery requires careful planning to ensure that the electrical infrastructure meets the power needs of the machines. The installation process includes ensuring adequate power supply capacity, grounding systems, and compliance with local building codes. In some cases, manufacturers may need to upgrade their electrical systems to accommodate more powerful machinery.

In terms of environmental impact, power usage is a critical factor. High energy consumption contributes to a larger carbon footprint, especially if the energy used is not from renewable sources. To mitigate this impact, manufacturers can adopt energy-efficient practices, invest in renewable energy sources, and implement measures to reduce waste and emissions during production.

Future Trends in Power Requirements

As the mattress manufacturing industry continues to evolve, power requirements for spring machinery are likely to become more energy-efficient. Advances in technology will lead to machines that consume less energy, operate more efficiently, and provide better overall performance. Additionally, as sustainability becomes a priority for many industries, manufacturers may invest in machines that can integrate renewable energy sources, further reducing environmental impacts.

Conclusion

Understanding the power requirements for mattress spring machinery is essential for manufacturers aiming to optimize production, reduce costs, and ensure safety. By considering factors such as power sources, energy efficiency, safety standards, and power management, manufacturers can improve their operational efficiency and minimize environmental impact. As technology advances, we can expect to see further improvements in energy-efficient machinery that will continue to shape the mattress manufacturing industry.