What is an Automatic Mattress Packing Machine?

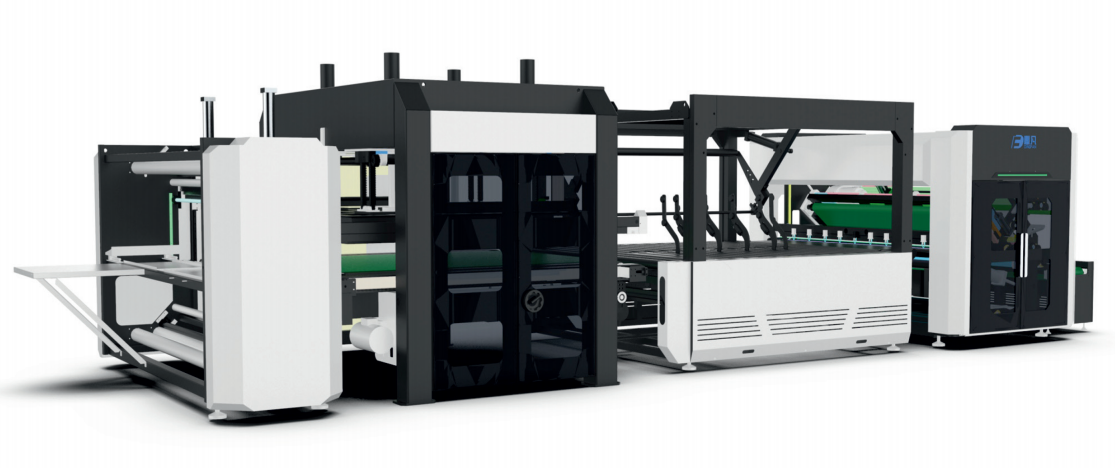

Introduction

In the modern mattress manufacturing industry, efficiency and product protection are crucial. An automatic mattress packing machine is a specialized piece of equipment designed to automate the final packaging process of mattresses. These machines help manufacturers save time, reduce labor costs, and ensure that mattresses are securely packed for storage and transportation.

How Does an Automatic Mattress Packing Machine Work?

1. Feeding System

The mattress is placed onto a conveyor belt, which moves it into the machine for processing.

2. Compression System

The machine applies pressure to reduce the volume of the mattress, making it easier to transport and store.

3. Sealing Mechanism

A protective plastic film wraps around the mattress, ensuring durability and resistance to external elements.

4. Rolling or Folding Mechanism

Depending on the mattress type, the machine either rolls or folds the compressed mattress into a compact shape.

5. Wrapping and Labeling

The final step includes wrapping the mattress securely and applying labels for easy identification and tracking.

Types of Automatic Mattress Packing Machines

1. Compression & Roll Packing Machines

- Best suited for foam and memory foam mattresses.

- Reduces shipping costs significantly.

- Commonly used for e-commerce and retail businesses.

2. Folding & Bagging Machines

- Ideal for innerspring and hybrid mattresses.

- Ensures the mattress retains its shape after unpacking.

- Used in large-scale manufacturing facilities.

3. Vacuum Packing Machines

- Uses vacuum technology to remove excess air.

- Provides airtight, space-saving packaging.

- Popular in high-end mattress production.

Benefits of Using an Automatic Mattress Packing Machine

1. Increased Efficiency & Productivity

Automating the packaging process speeds up production, reducing manual labor and increasing output.

2. Cost Savings

- Lower labor costs due to reduced manpower requirements.

- Minimizes material waste with precise packaging control.

- Decreases shipping expenses through compact packaging.

3. Improved Product Protection

- Prevents damage from dust, moisture, and physical impact.

- Enhances the customer experience with a neatly packed product.

4. Eco-Friendly & Sustainable

- Reduces plastic waste through optimized packaging.

- Energy-efficient machines lower carbon emissions.

Key Features to Consider When Choosing a Mattress Packing Machine

- Adjustable Compression Levels – Suitable for different mattress types and thicknesses.

- High-Speed Operation – Enhances productivity in high-volume manufacturing.

- User-Friendly Interface – Touchscreen controls for easy operation.

- Durable Sealing Technology – Ensures long-term product protection.

- Safety Features – Includes emergency stops and automated error detection.

Industries Benefiting from Automatic Mattress Packing Machines

- Mattress Manufacturers – Essential for large-scale production.

- Furniture Retailers & E-Commerce – Streamlines shipping and storage.

- Logistics & Warehousing – Optimizes space and handling efficiency.

- Hospitality Industry – Ensures hygiene and quality control in hotels and resorts.

Conclusion

Automatic mattress packing machines are revolutionizing the mattress industry by improving efficiency, reducing costs, and enhancing product protection. As the demand for compact and durable packaging grows, investing in the right mattress packing solution can significantly boost business competitiveness.

For businesses looking to streamline their production line and improve packaging standards, adopting an automatic mattress packing machine is a game-changer.

Looking for the best automatic mattress packing solutions? Contact us today for more information and customized solutions!