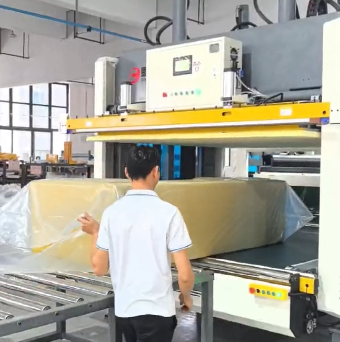

As the mattress industry evolves, automation has transformed packaging processes, setting new standards for efficiency, quality, and sustainability.

Automated packaging solutions improve speed, reduce costs, enhance safety, and ensure consistent quality—making them essential for modern mattress manufacturers.

How Does Automation Enhance Efficiency and Speed?

Traditional manual packaging is slow and labor-intensive, leading to bottlenecks in production.

Automated systems streamline packaging, increasing output and reducing delays.

Key Benefits of Automated Efficiency:

✔ Faster Processing: Machines package mattresses quicker than manual labor.

✔ Continuous Operation: No breaks, shift changes, or fatigue-related slowdowns.

✔ Optimized Production Flow: Integrates with conveyor systems for seamless packaging.

How Does Automation Ensure Consistent Quality Control?

Manual packaging can result in inconsistencies that affect product protection.

Automated machines follow precise guidelines, ensuring uniform and high-quality packaging.

Quality Control Advantages:

✔ Uniform Wrapping & Sealing: Each package meets exact specifications.

✔ Automated Sensors: Detect errors in real-time for immediate correction.

✔ Improved Product Protection: Proper sealing reduces damage in transit.

How Does Automation Reduce Costs?

Though automation requires an initial investment, the long-term savings are significant.

Lower labor expenses, optimized material usage, and fewer packaging errors lead to cost reductions.

Cost-Saving Factors:

✔ Reduced Labor Costs: Fewer workers are needed for manual packaging.

✔ Minimal Material Waste: Machines optimize packaging film and materials.

✔ Lower Return Rates: Better packaging reduces damaged shipments and replacements.

How Does Automation Improve Worker Safety?

Manual mattress packaging requires heavy lifting and repetitive motions, increasing injury risks.

Automated machinery handles strenuous tasks, creating a safer work environment.

Safety Benefits:

✔ Eliminates Heavy Lifting: Reduces worker fatigue and strain injuries.

✔ Fewer Workplace Accidents: Less manual handling leads to fewer injuries.

✔ Increased Employee Satisfaction: Workers can focus on less physically demanding tasks.

How Does Automation Improve Packaging Precision?

Automated packaging systems are programmed for precise measurements and sealing techniques.

This accuracy ensures optimized material usage and secure mattress packaging.

Precision Benefits:

✔ Exact Wrapping & Sealing: Reduces packaging inconsistencies.

✔ Optimized Material Usage: Prevents excessive packaging waste.

✔ Better Protection in Transit: Secure packaging minimizes product damage.

How Does Automation Offer Scalability and Flexibility?

As demand fluctuates, businesses need adaptable production systems.

Automated machines can scale output up or down without major operational changes.

Scalability Advantages:

✔ Adjustable Production Speeds: Matches varying demand levels.

✔ Easily Integrated with Existing Systems: Works with conveyors and inventory software.

✔ Adapts to Different Mattress Sizes: Packages multiple product types efficiently.

How Does Automation Support Sustainability?

Eco-friendly manufacturing is a growing industry priority.

Automated systems optimize packaging material usage and can incorporate recyclable solutions.

Environmental Benefits:

✔ Less Packaging Waste: Machines cut materials precisely, minimizing excess.

✔ Energy-Efficient Machinery: Reduces overall operational energy consumption.

✔ Supports Eco-Friendly Materials: Works with biodegradable and recyclable films.

How Does Automation Integrate with Supply Chains?

Seamless integration with logistics and inventory management improves efficiency.

Real-time tracking and data collection enhance production planning and distribution.

Supply Chain Advantages:

✔ Automated Inventory Updates: Prevents stock shortages and overproduction.

✔ Real-Time Tracking: Enhances shipment coordination and delivery accuracy.

✔ Better Forecasting: Data-driven insights optimize manufacturing schedules.

Conclusion

Automating mattress packaging offers substantial benefits, from increasing speed and reducing costs to improving safety and sustainability. By integrating advanced technology, manufacturers can enhance product quality, streamline operations, and remain competitive in the evolving market.

With the rise in demand for efficient, eco-friendly packaging solutions, automation is no longer optional—it’s the future of mattress manufacturing.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com