🚀 How many mattresses can a packaging machine handle in an hour?

🔧 The latest technology in mattress packaging machines is revolutionizing production, allowing manufacturers to scale up efficiency like never before!

In this guide, we’ll explore:

✔ How automation boosts packaging speed

✔ The impact of advanced compression and sealing technology

✔ How efficient packaging reduces costs and increases profitability

Let’s dive in! ⚡

Why Does Production Capacity Matter in Mattress Packaging?

The mattress industry is facing growing demand, with manufacturers needing faster and more efficient packaging to stay competitive.

✔ Manual packaging is too slow and leads to inconsistencies.

✔ Inefficient packaging wastes materials and increases costs.

✔ Optimized packaging improves logistics by reducing shipping volume.

💡 A high-capacity mattress packaging machine can process hundreds of mattresses per hour, ensuring a streamlined supply chain while reducing costs.

1️⃣ Understanding the Role of Mattress Packaging Machines

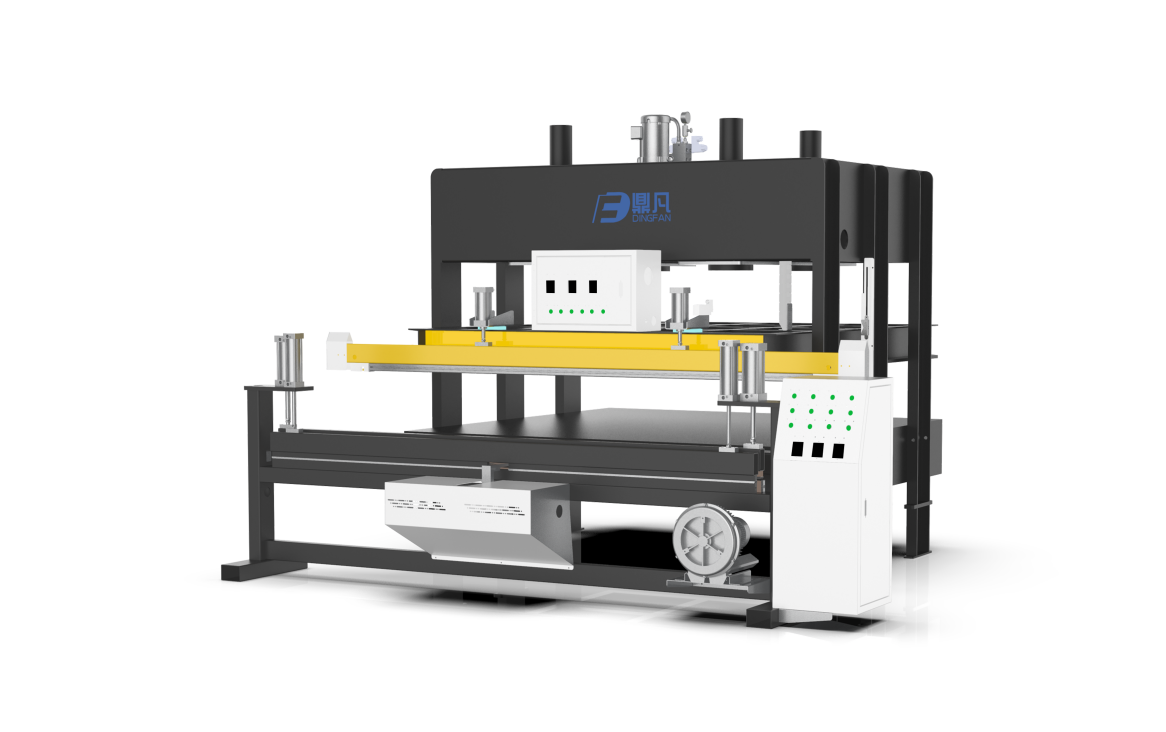

A mattress packaging machine is an automated system that:

✔ Wraps the mattress with protective material.

✔ Compresses it to reduce its volume.

✔ Seals it securely for storage and transport.

🎯 The goal? To speed up production, minimize damage, and ensure a consistent, professional finish on every package.

2️⃣ The Technological Advancements Behind High-Capacity Machines

⚡ Automation & Robotics

✔ Automated wrapping systems handle different mattress sizes effortlessly.

✔ Sensors & PLCs (Programmable Logic Controllers) ensure precise wrapping & sealing.

🔥 High-Pressure Compression Technology

✔ Reduces mattress volume by up to 75% for efficient shipping.

✔ Enables compact roll packaging for better storage and transport.

📡 Smart Software & AI Integration

✔ Optimizes machine speed & material usage based on mattress type.

✔ Detects errors in real time, reducing downtime.

📌 Result: Higher efficiency, lower material waste, and faster packaging cycles!

3️⃣ Speed & Efficiency: How Many Mattresses Can Be Packaged Per Hour?

⏳ Manual vs. Automated Packaging: A Comparison

| Method | Packaging Speed | Consistency | Labor Requirement |

|---|---|---|---|

| Manual Packaging | 5-10 mattresses per hour | Low | High |

| Semi-Automatic Machines | 20-50 mattresses per hour | Medium | Medium |

| Fully Automatic Machines | 150+ mattresses per hour | High | Low |

🎯 A fully automated system can package a mattress in under a minute!

💡 What this means for manufacturers:

✔ Faster order fulfillment for bulk production.

✔ Reduced labor costs by eliminating manual packaging.

✔ Consistent quality in every packaged product.

4️⃣ Quality Control & Consistency: The Key to Mass Production

Even with high-speed packaging, consistency is crucial.

🚀 How automation ensures perfect packaging:

✔ Uniform wrapping & sealing prevents loose packaging.

✔ Sensors monitor each stage to detect errors.

✔ Adjustable compression settings protect different mattress types.

📌 The result? Fewer defects, reduced damage, and a better customer experience.

5️⃣ The Cost-Effectiveness of High-Capacity Packaging Machines

Investing in automation reduces costs across multiple areas:

✔ 🔻 Lower labor costs – fewer workers required.

✔ 🔻 Less material waste – optimized use of packaging film.

✔ 🔻 Lower shipping costs – compressed packaging means more mattresses per truckload.

📌 ROI Calculation Example:

If an automated machine increases production by 200% and reduces labor by 50%, the investment pays for itself in months!

6️⃣ How Efficient Packaging Benefits Logistics & Distribution

Smaller packages = Lower transportation costs

💡 A roll-packed mattress takes up 70% less space than a traditionally packed one!

📦 How does this impact logistics?

✔ More mattresses fit into containers & trucks = lower shipping costs.

✔ Easier handling for distributors and retailers.

✔ Reduces storage space requirements in warehouses.

📌 The result? A leaner, more efficient supply chain that saves time & money.

7️⃣ Future Trends: What’s Next for Mattress Packaging Machines?

🧠 AI-Driven Optimization

✔ AI-powered real-time packaging adjustments based on material & mattress type.

🌱 Sustainability Initiatives

✔ Machines designed for biodegradable & recycled materials.

📡 Industry 4.0 Connectivity

✔ Cloud-based machine monitoring for predictive maintenance.

Conclusion: The Power of High-Capacity Mattress Packaging Machines

A high-performance mattress packaging machine can dramatically boost production by offering:

✔ Faster packaging speeds (150+ mattresses per hour).

✔ Lower labor & material costs through automation.

✔ Optimized storage & shipping with compression technology.

✔ Consistent quality & better logistics for global distribution.

🎯 Final Takeaway: Investing in a high-capacity mattress packaging machine is the key to scalability, efficiency, and profitability in the modern mattress industry! 🚀

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com