Without proper edge sewing, even a premium mattress can fall apart, lose shape, or disappoint your customers.

Mattress tape edge machines improve mattress structure, visual finish, and durability—while speeding up production and lowering labor costs.

In this article, I’ll explain how tape edge machines work, their types, what materials they use, and how they contribute to product quality and efficiency.

What Are Mattress Tape Edge Machines?

Poorly stitched mattress edges cause fraying, shifting layers, and customer returns.

Tape edge machines stitch binding tape securely around mattress edges, protecting internal layers and giving a clean, professional finish.

What Does the Machine Actually Do?

The machine drives a sewing head along the mattress edge, feeding and stitching a woven tape strip in one continuous motion. It:

- Secures top and bottom panels

- Seals border foam or spring packs

- Enhances visual appeal

This tape is more than decoration—it’s a structural seal.

| Function | Result |

|---|---|

| Secures edge structure | Prevents internal shifting |

| Hides seams and borders | Cleaner, premium product finish |

| Adds compressive tension | Improves edge hold and support |

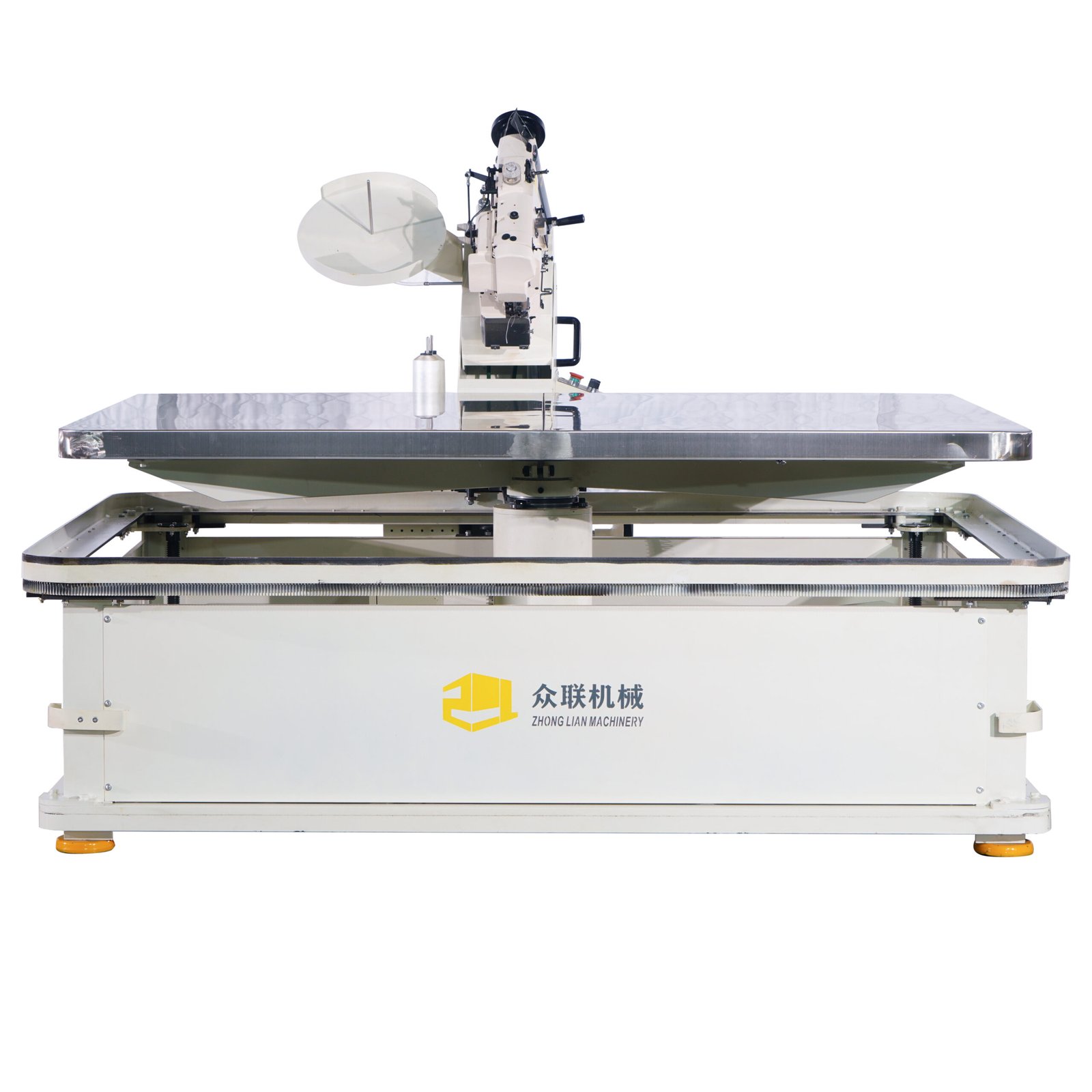

What Are the Main Parts of the Machine?

A well-built tape edge machine includes powerful drive systems and precise feeding mechanisms.

The machine includes a sewing head, tape feed system, motor drive, control panel, and a rotating platform (for manual models).

Key Components

🧵 Sewing Head

- Heavy-duty needle system with adjustable tension

- Handles thick materials like border foam and quilted tops

🧵 Tape Feeder

- Aligns and feeds decorative tape consistently

- Ensures no bunching or folding

⚙️ Motor and Drive

- Servo motor for consistent speed

- Drives needle, feeder, and movement arms

🔄 Mattress Rotation Table

- Manual, semi-automatic or fully auto rotating worktable

- Keeps stitching continuous around corners

| Component | Function in Operation |

|---|---|

| Sewing Head | Creates tight, uniform stitches |

| Tape Feeder | Positions edge tape precisely |

| Servo Motor | Drives all movement and needle control |

| Table Platform | Helps operator rotate mattress smoothly |

How Adaptable Are Tape Edge Machines to Different Mattress Sizes and Types?

Tape edge machines are impressively versatile, engineered to tackle a huge variety of mattress sizes and constructions—from slender twin beds to massive California kings. Adjustments in machine width, length, and thickness capacity mean you can stitch everything from compact RV bunks to plush euro-top behemoths.

But adaptability doesn’t stop at size. These machines also offer a range of stitching options, including single-sided, double-sided, and even four-sided configurations. So, whether you’re finishing a basic innerspring mattress or a custom hybrid with layers that defy traditional borders, there’s a setup to match.

The result? Instead of being pigeonholed into one product line, your tape edge machine can pivot seamlessly between contract jobs and high-end boutique orders—meeting diverse customer specifications without slowing down your production floor.

What Types of Tape Edge Machines Are Available?

Each machine type serves a different production level and factory size.

There are 3 types: manual, semi-automatic, and fully automatic.

Popular Tape Edge Machine Configurations

Within each category—manual, semi-automatic, and fully automatic—you’ll find a range of models to match the needs of different mattress production lines. Some popular configurations include:

- Automatic tape edge workstations: Ideal for high-output factories, these models offer features like programmable stitching patterns, adjustable speed controls, and integrated conveyor systems for uninterrupted workflow.

- Electronic drive tape edge machines: These provide precision control and are well-suited for mid-sized operations, often including digital touch panels, variable speed settings, and enhanced safety features.

- Dual servo tape edge stations: Designed for maximum efficiency, these advanced setups use servo motors for both the sewing head and table, allowing for faster processing and more consistent stitch quality—great for large-scale manufacturing.

Manufacturers like Global Systems, Resta, and Porter International offer a variety of these models, so you can tailor your machine choice to your factory’s capacity and automation needs.

1. Manual Tape Edge Machines

- Operator controls rotation and stitch speed

- Ideal for custom or small batch production

- Lower cost, higher skill requirement

2. Semi-Automatic Machines

- Auto tape feeding, manual mattress rotation

- Balanced speed and operator control

- Suitable for medium-volume manufacturers

3. Fully Automatic Machines

- Automated mattress rotation, tape feed, and cutting

- Used in large factories for mass production

- Reduces labor needs, increases daily output

| Machine Type | Output/Day | Operator Skill | Investment |

|---|---|---|---|

| Manual | 30–60 pcs | High | Low |

| Semi-Auto | 60–120 pcs | Medium | Medium |

| Fully Auto | 150–250 pcs | Low | High |

What Advancements in Automation Are Anticipated for Tape Edge Machines?

Mattress manufacturing isn’t standing still—neither are the machines at its heart. The next wave of tape edge machines is all about making smart work even smarter, with modern automation driving both accuracy and speed.

Smarter Technology on the Horizon

Expect to see tape edge machines using advanced sensors and control systems—think tech you’d find in high-end automotive assembly lines or German precision robotics (like Siemens or Omron controls). These upgrades will allow machines to:

- Monitor stitch quality and speed in real time

- Automatically adjust stitch length and tension mid-operation

- Detect material inconsistencies before they become costly errors

All this means the machine, rather than the operator, takes charge of nuance—significantly reducing human error and ensuring every mattress edge comes out consistent and clean.

Truly Hands-Off Operation

Beyond the basics, future models are set to feature:

- Automatic thread changers that swap spools without stopping production

- Self-adjusting guides that re-position for each mattress size or thickness

- Onboard systems that “see” the mattress dimensions and alter sewing paths accordingly

With these advancements, a skilled operator can oversee multiple machines—bringing the efficient, “lights out” factory floor from car manufacturing straight to mattress production.

What Does This Mean for Manufacturers?

- Faster changeovers between product types

- Fewer defects and returns

- Lower training requirements for operators

- Streamlined workflows even as product variety increases

In short: as automation and intelligence continue to evolve, mattress factories will be better equipped to meet changing customer demands quickly, efficiently, and reliably.

What Materials Are Used in Edge Sewing?

Choosing the right edge tape matters just as much as the machine.

Common tape materials include polyester, cotton, or blended fibers—each with unique properties.

Material Comparison

| Material | Pros | Best Used For |

|---|---|---|

| Polyester | Strong, colorfast, heat-resistant | Budget or standard models |

| Cotton | Soft touch, breathable, natural look | Premium, organic mattresses |

| Blended | Combines strength and softness | Mid-range products |

Tape Design Options

Manufacturers can also choose different:

- Widths: 1.5–3 inches

- Colors: White, beige, black, or brand color

- Weaves: Herringbone, plain, or logo patterns

The tape also acts as a subtle branding element.

How Does the Machine Operate?

Understanding the flow helps operators and managers optimize setup.

The tape is fed into the sewing head, the mattress is moved/rotated, and the edge is stitched with high-speed precision.

Operation Steps

- Load mattress onto table

- Feed edge tape into machine

- Align tape with edge seam

- Start stitching and guide mattress edge

- Machine rotates and continues stitch

- Auto tape cutter trims the end

- Operator unloads finished mattress

Full cycle time: 90–180 seconds, depending on mattress size and machine type.

How Do These Machines Improve Efficiency?

If your current bottleneck is finishing or edge stitching—this is your solution.

Modern tape edge machines reduce cycle time, lower rework rates, and need fewer skilled operators.

Key Efficiency Gains

- 🔁 Faster Edging: From 6+ minutes down to under 2 minutes

- ✅ Consistent Stitching: Same tension and overlap on every corner

- 👷 Lower Labor Needs: 1 person can operate multiple auto machines

- 📦 Less Rework: No fraying, crooked seams, or loose tape

Real Use Case

| Factory Type | Before (Manual) | After (Auto Machine) |

|---|---|---|

| Edge Sewing Time | 5–6 min/unit | 2 min/unit |

| Operators Needed | 2–3 per station | 1 per machine |

| Tape Error Rate | 6% | <1% |

ROI achieved in under 12 months in a medium-sized Vietnamese factory.

Smarter Machines on the Horizon

What’s next for tape edge machines? Expect even more intelligence packed into every stitch.

Next-generation models are being designed with advanced sensors, real-time monitoring, and self-adjusting controls. These innovations mean machines will automatically detect variations in fabric, adjust tension on the fly, and correct issues before they slow down your line.

Key Innovations to Watch For

- Real-Time Quality Control: Sensors will catch even tiny misalignments or missed stitches instantly—think of it as having a vigilant supervisor in every unit.

- Automatic Parameter Adjustment: Machines will tweak their own sewing speed and pressure to match different fabrics or edge materials seamlessly, with no manual intervention.

- Predictive Maintenance Alerts: Just like your car reminds you when it’s time for a service, smart machines will flag maintenance needs before breakdowns happen, slashing downtime.

- Data-Driven Insights: Integration with factory management systems will allow for instant production reports, efficiency tracking, and intelligent optimization.

With leaps like these, tape edge machines will require even less oversight, keep efficiency high, and push both consistency and quality to new levels—making them a strategic investment for any mattress line looking to stay ahead.

What Maintenance Is Required?

Even great machines need care to stay smooth.

Clean, oil, and inspect key parts weekly to prevent tape jams or thread breaks.

Maintenance Checklist

| Task | Frequency |

|---|---|

| Clean needle area & feeder | Daily |

| Lubricate needle bar | 2x/week |

| Inspect tape tension wheel | Weekly |

| Replace worn needle | Monthly |

Also keep a logbook to track part replacements and service calls.

What Are the Future Trends for Tape Edge Machines?

Just as rotary phones gave way to iPhones, tape edge machines are set for a tech leap.

Smarter, Not Just Faster

Tomorrow’s tape edge machines are shaping up to be digital sidekicks on the production line. Expect to see smarter systems with more sensors, real-time quality monitoring, and on-the-fly adjustments. Think of it as the machine watching its own stitching and tweaking tension or speed mid-seam, so you don’t have to.

- Built-in sensors: Flag issues as they happen—no more unnoticed skipped stitches.

- Automated feedback: Adjusts parameters instantly for every mattress type or thickness.

- Diagnostics: Alerts you before a needle snaps, not after you’ve got a jam.

Ramping Up Automation

Automation will continue its march. The next generation isn’t just about feeding tape on its own. We’re talking:

- Automatic thread changes

- Self-adjusting paths for mattresses of any size

- Hands-free switching of stitch styles or densities

Some prototypes in Europe and Japan already handle variable mattress shapes with hardly an operator in sight. This means matching output to market demand gets easier than locating the end of a roll of packing tape.

Integration with Smart Factory Ecosystems

- Remote machine monitoring from your smartphone

- Production data uploaded to the cloud—analyzing downtime and spotting trends

- Compatibility with Industry 4.0 systems for lean manufacturing

With these advancements, expect tape edge machines that practically run themselves, minimize rework even further, and feed live production data straight to your floor manager’s dashboard.

In short: less manual fiddling, more consistent quality, and serious scale-up potential.

Conclusion

Mattress tape edge machines are the final step that holds everything together—literally and visually. Choosing the right model and maintaining it well gives you the edge in quality, efficiency, and customer satisfaction.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com