The market is growing fast, but many mattress factories still suffer from unstable machines and high maintenance costs.

To ensure mattress quality in this booming market, factories must rely on stable, efficient, and easy-to-operate machinery with high automation and durable components.

In this article, I’ll break down 10 proven ways we use to guarantee machine quality—methods that help our customers improve productivity, reduce costs, and stay competitive.

What Are the Key Industry Standards for Mattress Machinery?

If you’re worried about whether a machine is "qualified"—you’re not alone.

International certifications like ISO 9001, CE, and UL are the first signs a machine meets global safety and quality benchmarks.

Standards exist for a reason. As a machinery supplier, we follow ISO 9001 for quality control and ISO 14001 for environmental compliance. For our clients in Europe or North America, CE and UL marks are often a must. They show that our machines are not just well-built, but also globally accepted. Besides the papers, we often show live testing videos or allow on-site inspections before purchase.

Common Standards in the Industry

| Certification | Focus | Why It Matters |

|---|---|---|

| ISO 9001 | Quality Management | Ensures internal systems to control quality |

| ISO 14001 | Environmental Compliance | Reduces waste and energy use |

| CE | European Market Safety | Mandatory for EU imports |

| UL | Electrical Safety (North America) | Ensures electronic stability |

Why Do Materials and Core Parts Matter So Much?

Cheap materials might save upfront cost, but long-term? More downtime, more headaches.

We use high-strength steel, branded bearings (like NSK/SKF), and CNC-cut aluminum parts to ensure precision and reliability.

Every component matters. We manufacture over 80% of our core metal parts in-house. This ensures every gear, motor bracket, or knife blade fits perfectly—no need to wait weeks for replacements. For example, our machines use H13 hardened steel in spring-forming cutters, and wear-resistant belts that last 12–24 months before needing replacement.

Table: Materials and Usage

| Component | Material | Reason |

|---|---|---|

| Frame & Base | Q345 steel / 304 SS | Durable, anti-rust |

| Cutters & Rollers | H13 alloy steel | High wear-resistance |

| Bearings | NSK/SKF | Low friction, long life |

| Electric System | Omron / Schneider | Global compatibility |

How Often Should Mattress Machinery Be Maintained?

A broken-down machine during peak season? Nightmare.

We recommend inspecting machines every 3–6 months, with part replacements planned based on wear cycles.

Good machinery doesn’t mean maintenance-free. Even our top machines need lubrication, belt inspection, and knife replacement regularly. We offer maintenance checklists and video training, and some clients even sign yearly service contracts with us. Preventive maintenance reduces unplanned downtime and keeps mattress quality consistent.

Common Wear Parts and Lifespan

| Part | Typical Life | Notes |

|---|---|---|

| Forming Knife | 3–6 months | Replace based on spring wire hardness |

| Heat Seal Cutter | 6 months | Especially for plastic packaging |

| Conveyor Belt | 1–2 years | Check tension monthly |

| Bearings | 12+ months | Grease regularly |

Why Does Operator Training Impact Product Quality?

A good machine in untrained hands is like a Ferrari with no driver’s license.

We provide onsite and video training so operators can safely run and adjust our machines for different spring types and mattress specs.

Our PLC touchscreen systems are intuitive, but training is still crucial. We usually train your team to handle up to 5 different spring types using preset parameters. Certified operators also reduce machine damage and waste from bad setups. One trained worker can often run two machines at once, reducing labor cost.

What Role Does Automation and Technology Play?

Manual machines struggle with modern mattress production, especially in large factories.

Our machines come with PLC control, servo motors, touchscreens, and smart sensors to automate nearly every step.

Automation doesn’t just mean pressing a button. Our machines detect spring misfeeds, missing bags, or tension problems automatically. In high-end models, settings adjust automatically based on spring specs. Some of our clients even monitor real-time data remotely, helping their managers adjust production based on live KPIs.

Example: Smart Functions We Offer

- Automatic spring size recognition

- Real-time defect alarms (empty/missing spring, loose bag)

- Remote monitoring via Ethernet

- Memory presets for 20+ spring models

How to Set Up Reliable Quality Control Tests?

Even if a machine runs today, how do you know it’ll run well 6 months later?

Every machine we build is tested under full load with actual spring or mattress samples before shipment.

We simulate production environments during our final inspection. For example, we might run 10,000 springs through a pocket spring machine before packaging. We check sealing quality, tension strength, and spring compression balance. Only when it passes all metrics do we allow delivery.

Final Testing Checklist (Simplified)

- ✅ Speed test (max RPM)

- ✅ Load test (spring compression range)

- ✅ Sealing integrity test

- ✅ Control panel & sensor accuracy

Should You Only Buy from Reputable Suppliers?

If you don’t know who made the machine, how can you trust what’s inside?

Always verify the supplier’s factory, certifications, and customer references before buying.

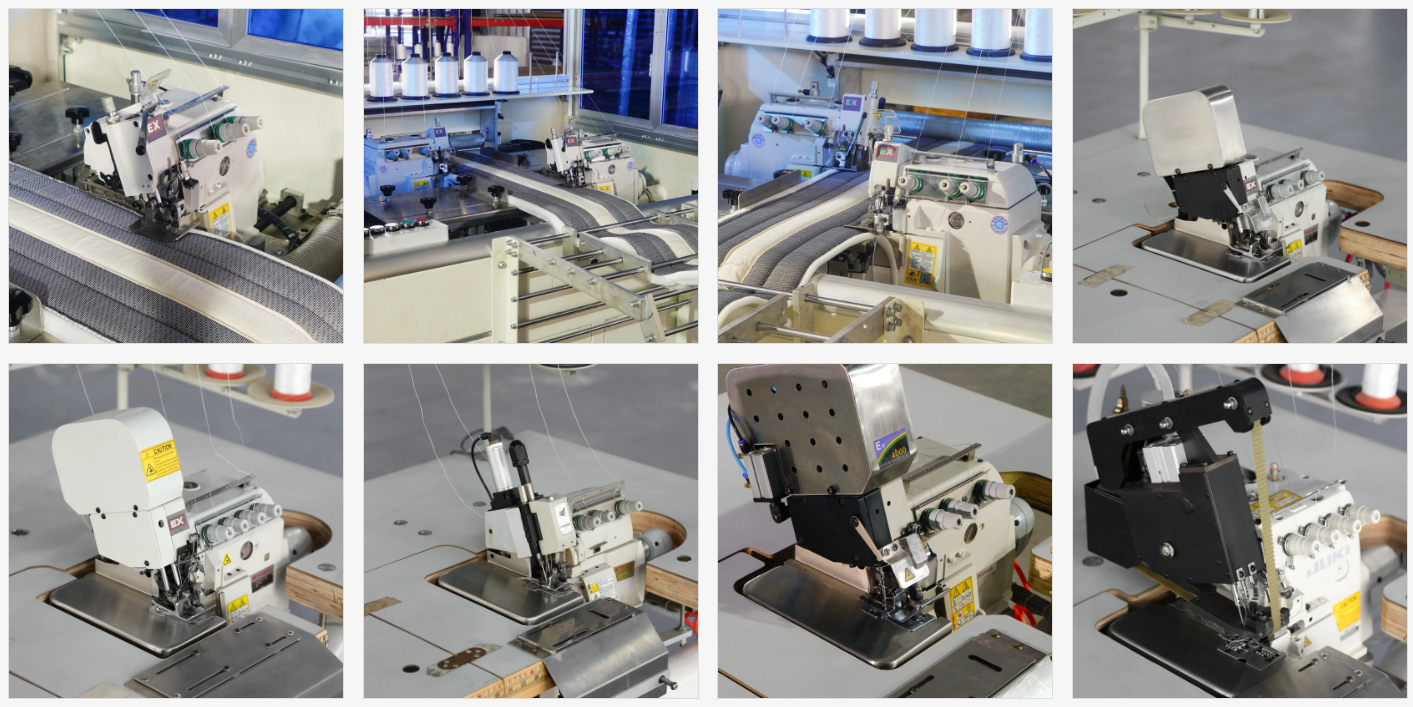

We’re proud to manufacture everything under one roof—over 130 workers in a 28,000㎡ plant. All parts, from frames to control panels, are inspected before assembly. We also welcome video calls, factory tours, and even third-party audits. It’s your investment—you deserve to know who builds your machinery.

Can Data Help You Make Better Decisions?

Numbers don’t lie. But only if you can collect them.

Smart machines now log runtime, defect rate, cycle count, and energy use—helping managers spot issues before they cause losses.

With one glance, you can see if Machine A is running below its normal 130 springs/min, or if Machine B suddenly has a higher seal-failure rate. We’ve helped customers reduce machine idling by 20% just through data insights.

Key Data Metrics

| KPI | Why It Matters |

|---|---|

| Cycle Count | Measures throughput |

| Downtime Logs | Identifies weak parts |

| Defect Rate | Quality control |

| Energy Consumption | Reduce electricity bills |

How Can You Continuously Improve Your Production Line?

Great machines today might not be great next year.

We offer upgrade modules, software updates, and continuous R&D to help clients stay ahead of market changes.

Some clients ask for bag width adjustment upgrades. Others want new tension control algorithms for thinner springs. Whatever it is—we keep the machine “alive” long after delivery. With remote updates and modular designs, you don’t need to buy a new machine just to handle new product specs.

Are Machines Compliant with Environmental and Safety Rules?

Buyers today care about sustainability—and so should you.

Our machines meet low-noise, low-energy, and low-waste standards, while also offering full safety systems like emergency stops, guarding doors, and overload protection.

We reduce plastic use in packaging by up to 30%. Some models run on as low as 15kW and use noise-dampening shells. From factory floors to product shipment, we help you go greener without hurting your margins.

Conclusion

With the right machines, factories can win in quality, speed, and cost. Don’t cut corners—choose quality machinery, and it’ll pay you back every day.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com