Rising energy costs and stricter environmental regulations are hitting mattress factories hard—standard machines simply waste too much power.

Energy-efficient mattress machinery helps reduce electricity bills, lower emissions, and improve sustainability—all while maintaining high output.

This article explains how to assess energy use in mattress production, what technologies to adopt, and how manufacturers like us can reduce both costs and our environmental footprint.

What’s the current energy usage in mattress production?

Energy bills keep climbing, especially in factories running outdated equipment across multiple shifts.

Mattress production involves high electricity use in cutting, sewing, assembling, and packaging—often reaching 50,000–100,000 kWh per month for mid-size factories.

Major Energy Consumers in Mattress Manufacturing

| Process Stage | Machinery Used | Energy Usage (Est.) |

|---|---|---|

| Cutting | CNC cutters, laser cutters | High—precision motors |

| Quilting | Multi-needle sewing heads | Medium—continuous operation |

| Assembly | Glue rollers, press units | Medium to high |

| Packaging | Compressors, sealing units | Medium |

Peak energy demand often happens during large batch production or promotional periods, meaning inefficient machines create bigger cost spikes.

What new technologies improve energy efficiency?

Many factories still run machines that were never designed with energy efficiency in mind.

Modern machines come with servo motors, smart sensors, and sleep modes—allowing energy use to scale with production needs.

Energy-Saving Technologies You Should Look For

- Servo motors: Use power only as needed—no idle waste

- Sleep mode: Puts the machine in standby when not operating

- Precision tool paths: Complete cuts or glue passes in fewer moves

- IoT monitoring: Track energy usage live and adjust performance

We’ve seen clients reduce machine energy consumption by 20–30% just by upgrading to newer models with these features.

What are practical steps to improve energy efficiency?

Many mattress manufacturers know energy is wasted—but don’t know where to start fixing it.

Maintenance, upgrades, and staff training are three easy ways to reduce energy waste quickly.

3-Step Action Plan

1. Regular Maintenance

- Clean filters, lubricate parts, and align cutters

- Avoids overloading motors due to resistance or friction

2. Upgrade Old Machines

- Replace motors with servo types

- Swap out inefficient glue systems for controlled roller types

3. Train Your Staff

- Turn off idle equipment

- Use machines at optimal load instead of full throttle at all times

Just teaching staff to enable “energy saving mode” at the end of each shift can save thousands in power bills each year.

Is energy-efficient equipment worth the investment?

Upfront costs make some factories hesitate—but not upgrading means you keep overpaying for electricity every month.

A typical energy-efficient machine pays for itself within 12–24 months through reduced electricity and fewer breakdowns.

Example ROI Table

| Machine Type | Standard Power Use | Upgraded Power Use | Monthly Savings (¥) | Payback Time |

|---|---|---|---|---|

| Glue Roller System | 3.5 kWh/hr | 2.1 kWh/hr | ¥1,500 | 14 months |

| Quilting Machine | 4.8 kWh/hr | 3.0 kWh/hr | ¥2,200 | 18 months |

| Sealing Unit | 2.2 kWh/hr | 1.3 kWh/hr | ¥1,100 | 12 months |

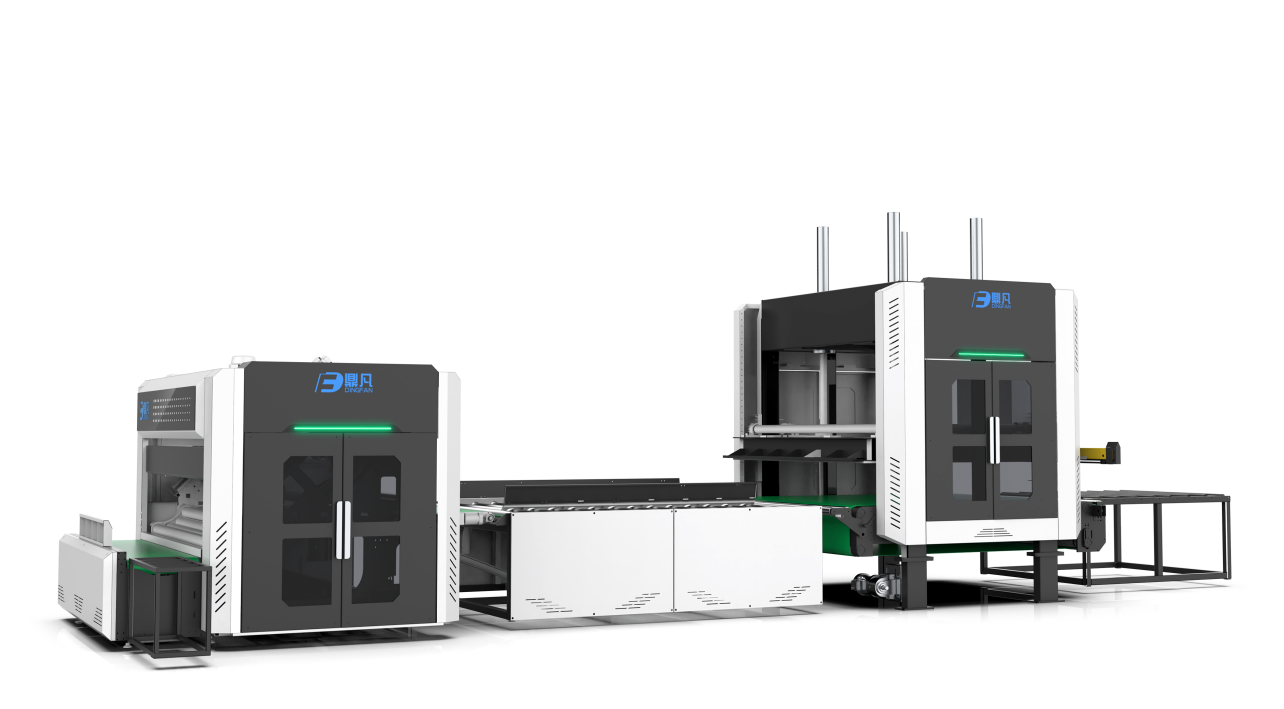

In our case, after upgrading our DF-F07 film packaging machines, we saw a 22% drop in monthly energy use—and better sealing consistency.

How does energy-efficient machinery help the environment?

Customers today don’t just want cheaper mattresses—they want cleaner ones too.

Lower energy consumption reduces CO₂ emissions, aligns with climate goals, and appeals to eco-conscious buyers.

Every kilowatt saved helps:

- Reduce carbon footprint per mattress

- Improve ESG scores for your brand

- Attract eco-conscious B2B buyers (especially in EU/US markets)

Example Impact

A factory saving 20,000 kWh/month avoids over 12 tons of CO₂ emissions annually. That’s equal to planting 500+ trees per year.

Are there incentives for switching to energy-efficient machines?

Governments want manufacturers to cut emissions—and many offer grants to help.

Depending on your country, you may qualify for rebates, tax relief, or low-interest loans when you upgrade to energy-efficient machinery.

Incentive Types to Look For

- Local utility rebates on efficient motors

- Carbon footprint reporting benefits (especially in Europe)

- Green factory certifications (eligible for tender bonuses in Southeast Asia)

We helped one of our Vietnam clients apply for a 30% co-funding program through a local SME green tech grant. The upgrade paid for itself even faster.

What challenges do factories face when going energy-efficient?

Going green sounds good—but some factories fear disruptions or hidden costs.

The top concerns are integration issues, training time, and unclear ROI—but all can be handled with proper planning.

Problem vs. Solution Table

| Challenge | Solution |

|---|---|

| Machine doesn’t fit old line | Use modular designs with standard dimensions |

| Operators don’t know new tech | Offer bilingual video training and hands-on onboarding |

| Budget constraints | Start with partial upgrades—highest power machines first |

| ROI hard to predict | Ask suppliers for real-world usage benchmarks |

We offer remote diagnostics and training support to ensure minimal disruption during the switch.

What’s the future of energy efficiency in mattress manufacturing?

The next decade will be driven by smart factories—and mattress machinery is no exception.

Expect AI-driven energy optimization, real-time efficiency dashboards, and full supply-chain visibility.

Upcoming Trends

- AI-controlled motor loads that self-adjust based on material thickness

- Energy scoring systems by machine/operator

- Factory-wide power optimization software

- Integration with solar or off-grid systems

The factories who lead in energy efficiency will not just save costs—they’ll win bigger contracts and improve brand trust.

Conclusion

Switching to energy-efficient mattress machinery helps cut electricity bills, reduce emissions, and future-proof your factory against rising energy costs and regulations.