Making the wrong choice in mattress machinery can cost you time, money, and production efficiency. But making the right choice? That can transform your entire factory.

To choose the right mattress machinery, you need to align your equipment with your production needs, automation goals, space layout, and budget. Look for machines with high reliability, scalability, and strong after-sales support.

As someone who works closely with mattress factories in Southeast Asia and beyond, I’ve seen how the right machinery makes production smoother and more profitable. Let me show you what to consider before you invest.

What are your actual production requirements?

Buying machinery without knowing your needs is like buying shoes without knowing your size. It simply doesn’t work.

Before selecting any equipment, define your daily, weekly, and monthly mattress output, as well as the types of mattresses you plan to produce.

Some of my clients manufacture only spring mattresses; others do latex, memory foam, or hybrids. These differences directly impact machinery choice. Innerspring mattresses require pocket spring machines or coiling units. Memory foam setups need precise foam cutting tools and glue lines. Hybrid lines may need both.

Here’s a simple checklist I give to clients:

✅ Basic Production Questions:

- How many units per day?

- Do you use manual labor or plan for automation?

- Will you switch frequently between different mattress types?

✅ Matching Output to Equipment:

| Production Volume | Suggested Equipment Type |

|---|---|

| <100 pcs/day | Manual/Semi-auto machines |

| 100–300 pcs/day | Semi-auto + modular upgrades |

| 300+ pcs/day | Fully automated production lines |

Starting with a clear plan helps you avoid overbuying or under-investing.

What types of machinery are essential for your workflow?

There’s no one-machine-fits-all in mattress production. Every machine plays a role in building a quality product.

Common mattress machinery includes quilting machines, foam cutting machines, pocket spring machines, and tape edge sewing systems. Each machine handles a key part of the process.

Here’s how to think about it:

🔧 Core Machines for Production

| Function | Machine Type |

|---|---|

| Surface Finishing | Quilting Machine |

| Foam Shaping | CNC Foam Cutter |

| Core Support | Pocket Spring Machine |

| Final Assembly | Tape Edge Machine |

| Compression & Packing | Mattress Compression Roll Machine |

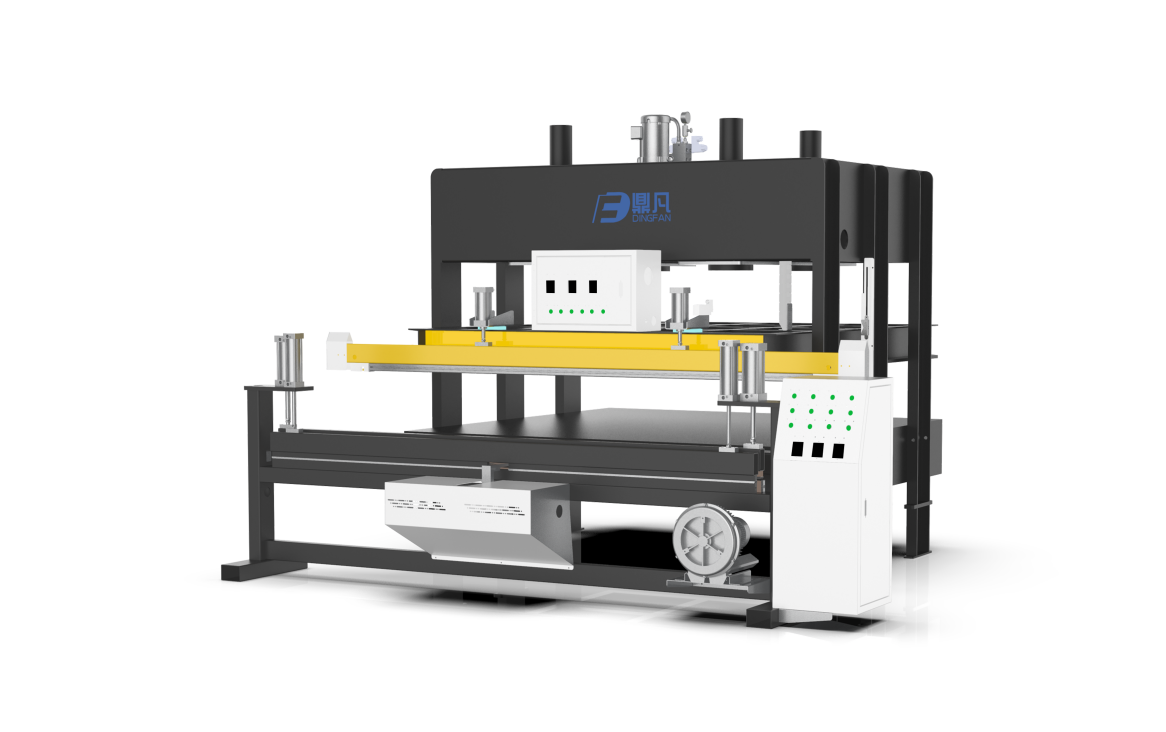

Look for machines that are modular or adaptable. For example, our DF-X02 mattress compression machine supports various mattress heights and automatically adjusts caliber size. That kind of flexibility reduces your need for multiple models.

How automated do you want your factory to be?

Labor is expensive. Errors are even more expensive. Automation reduces both.

Manual, semi-automatic, and fully automatic machines offer different trade-offs. Automation saves time, improves accuracy, and reduces dependence on skilled labor.

In Southeast Asia, many of our partners start with semi-automatic systems due to budget. But once production scales, the savings in labor and error reduction from automation are too compelling to ignore.

Here’s a quick automation comparison:

| Feature | Manual | Semi-Auto | Fully Automatic |

|---|---|---|---|

| Speed | Low | Medium | High |

| Labor Requirement | High | Medium | Low |

| Initial Cost | Low | Medium | High |

| Accuracy | Operator-driven | Sensor-driven | System-controlled |

| Ideal For | Startups | Growing factories | High-volume production |

For example, our DF-X17 production line is fully automatic and integrates compression, sealing, folding, and rolling—all in one. Clients with high output needs see ROI within 12–18 months.

Is the machinery built to last?

Buying low-quality machinery is like driving with a flat tire—you may move forward, but not for long.

Choose machinery made from durable materials with certified manufacturing standards. Reliability saves you from costly breakdowns and production delays.

Ask these questions before you buy:

- What’s the expected service life of the machine?

- Are parts like servo motors and PLCs from top brands (e.g., Omron, Schneider)?

- What’s the average downtime per year?

- Does it come with a parts replacement kit?

In our factory, we machine over 90% of our metal parts in-house. That ensures every bolt, bracket, and bearing matches perfectly. Precision equals reliability.

Will the equipment fit in your factory layout?

Even the best machine won’t help if you don’t have space to operate it properly.

Make sure your production area can accommodate the machine’s dimensions, operation zone, and maintenance access.

It’s not just about space—it’s about workflow. Here’s a simplified version of what I help customers map out:

📐 Layout Tips:

- Leave 1–1.5 meters of working space around each machine

- Group related processes: spring assembly near pocket coiling

- Keep packing areas near loading bays

- Avoid long walking paths for material handling

Here’s an example for a basic flow:

Coiling → Assembly → Gluing → Compression → Packaging

Proper layout increases safety, productivity, and efficiency.

How energy-efficient is the equipment?

Every hour your machine runs, it’s burning electricity. And in high-speed operations, those bills add up fast.

Choose machines with energy-saving features such as variable frequency drives, smart sensors, and sleep modes to lower your electricity bill.

Here’s a simple power cost example:

| Machine Type | Avg. Power (kW) | Hours/Day | Rate (USD/kWh) | Daily Cost |

|---|---|---|---|---|

| Semi-auto packer (DF-Y06) | 11 kW | 8 | 0.12 | $10.56 |

| Full auto line (DF-X16) | 45 kW | 8 | 0.12 | $43.20 |

Our DF-X03 integrates folding and rolling to save electricity by reducing machine operation time per cycle.

Energy savings = long-term cost savings.

What about maintenance and support?

Even the best machines need love. Maintenance isn’t optional—it’s a necessity.

Choose equipment that comes with easy maintenance access, documented service cycles, and responsive after-sales support.

What to look for:

- Does the supplier offer local support in your country?

- Are spare parts in stock and quickly shipped?

- Do they provide operator training?

- Is there remote diagnostic capability?

At our company, we ship a standard toolkit with every order and offer online video training for new operators. Clients love it because it cuts down training time and improves uptime.

How does the total cost break down?

Don’t just look at the sticker price. A cheaper machine may cost more over time.

Compare upfront price, installation cost, training, spare parts, maintenance, and energy usage to get a full picture of total cost of ownership.

Use this table for a full breakdown:

| Cost Element | Example Semi-Auto | Example Full Auto |

|---|---|---|

| Machine Price | $12,000 | $50,000 |

| Installation + Training | $1,000 | $3,000 |

| Annual Maintenance | $1,500 | $3,000 |

| Energy Cost (Year) | $2,400 | $7,800 |

| Labor Savings (Year) | – | $10,000 |

Higher automation typically pays off after 1–2 years. If your production is scaling, consider this early.

Conclusion

Choosing the right mattress machinery means balancing productivity, quality, and cost. Don’t just buy a machine—build a system that grows with your business.