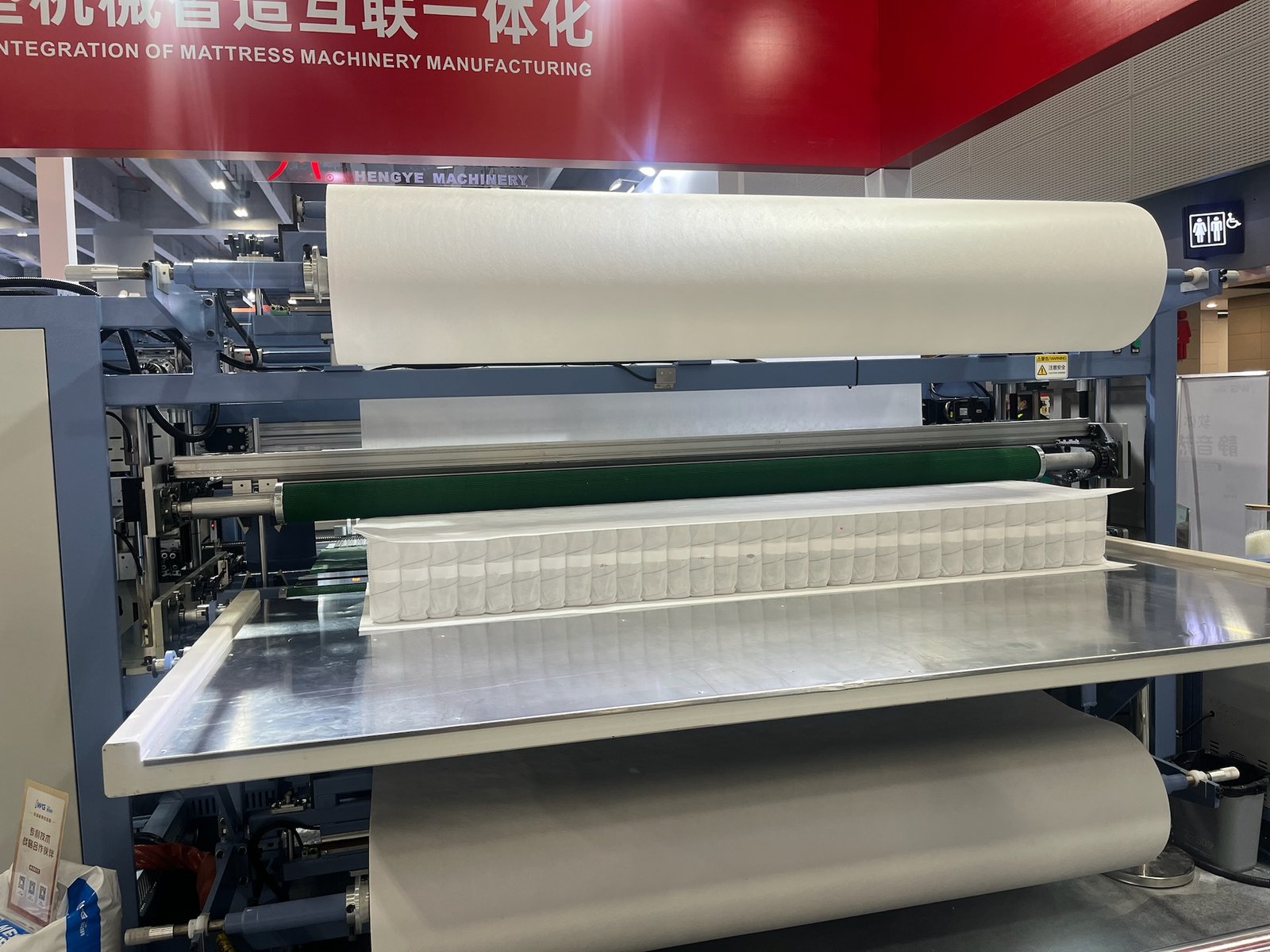

Mattress complaints often start with the springs—noisy, uneven, or sagging. That’s not a sales problem. It’s a quality control issue.

We ensure quality in mattress spring production through raw material checks, machine calibration, in-process testing, and strict inspection protocols.

If you’re running a mattress factory or buying machines, these quality steps are non-negotiable.

Why Does Raw Material Inspection Matter So Much?

Quality starts at the coil.

Steel wire is the backbone of every mattress spring. If it’s too soft, too brittle, or inconsistent in diameter—you’ll face problems down the line.

Here’s what we check:

| Property | Why It Matters | How We Test |

|---|---|---|

| Tensile strength | Prevents sagging or snapping | Pull testing (min 1700 MPa) |

| Diameter consistency | Ensures uniform coil dimensions | Laser micrometer |

| Surface condition | Avoids rust, noise, breakage | Visual and touch inspection |

We reject any batch that doesn’t meet spec. You should too.

What Role Do Certified Suppliers Play?

Certified suppliers aren’t just “nice to have”—they’re your insurance policy.

We only buy wire from ISO 9001-certified factories. Why?

Because:

- Their production is traceable

- They can issue a material test report

- Their quality systems are audited yearly

We also run quarterly audits on our suppliers. We visit, check their process, and verify that their test data matches our in-house results.

Don’t wait for customer complaints to find out you bought bad wire.

Can Machines Really Control Quality?

Yes—but only if you calibrate them properly.

Spring coiling machines must be accurate to ±0.5mm. Otherwise, your mattress will feel uneven or collapse early.

How we ensure precision:

- Weekly coil diameter checks with digital calipers

- Tension control sensors for wire feed

- Software auto-calibration before every shift

- Monthly machine-leveling with laser tools

We keep records of all calibration logs in case customers need a quality report.

Are In-Process Checks Really Necessary?

Absolutely. That’s where 90% of problems are caught.

At each stage, our staff performs fast, simple checks:

- During coiling: Check spring height and pitch every 100 pcs

- During gluing/bonding: Inspect for gaps, misalignments

- During heat-setting: Random pull-tests to verify tension recovery

We use red bins to hold any suspect coils—never let them into final packing.

How Do You Train Staff for Quality?

Even with great machines, quality depends on people.

That’s why we:

- Train every operator for 2 weeks before they touch machines solo

- Do monthly refreshers with hands-on drills

- Reward teams with the fewest rejects

We also post shift-level quality stats on the shop floor. When workers see their impact, they take ownership.

Should You Invest in Automated Testing?

If your volumes are high—yes.

Automated spring testers check compression, rebound, and height tolerance automatically. They work like this:

- Each spring is compressed to a set load (e.g., 50kg)

- Rebound height is measured via sensor

- Any deviation of >±1mm gets flagged and ejected

This lets you inspect 100% of springs, not just samples.

For smaller factories, spot-checks every 200–500 pcs still catch most problems.

What is SPC and Do You Need It?

SPC (Statistical Process Control) is how you track consistency over time.

We track:

| Metric | Goal |

|---|---|

| Coil height variance | < ±1mm |

| Reject rate per 1000 pcs | < 1% |

| Machine downtime | < 30 min/day |

We graph it daily. If the trend line drifts, we act fast.

Even if you don’t use advanced software, a basic Excel sheet + team review once a week can work wonders.

What Happens During Final Inspection?

Before packing, every batch goes through:

- Visual inspection – No rust, no deformed coils

- Dimension check – Random samples verified

- Load test – 1 out of 100 tested for compression and rebound

- Noise test – Coils pressed for any squeak

Failed springs go to the scrap bin—not to your customers.

We also include a QC label with batch number, date, and inspector name inside each roll.

How Do You Use Customer Feedback to Improve?

You can’t improve what you don’t track.

That’s why we:

- Call key customers monthly for spring feedback

- Collect failure returns and inspect root cause

- Update SOPs when the same issue happens 3+ times

For example, after two clients flagged noisy coils, we found one wire supplier had microscopic surface rust. We switched immediately.

Real-world use is your best test lab.

Conclusion

Quality control in mattress spring production isn’t a one-time fix. It’s a system of materials, machines, people, and checks—working together every shift.

If you get it right, you’ll reduce returns, increase repeat customers, and protect your brand.

That’s what quality really delivers.