What Types of Mattress Spring Machines Are Available on the Market?

In the mattress industry, the type

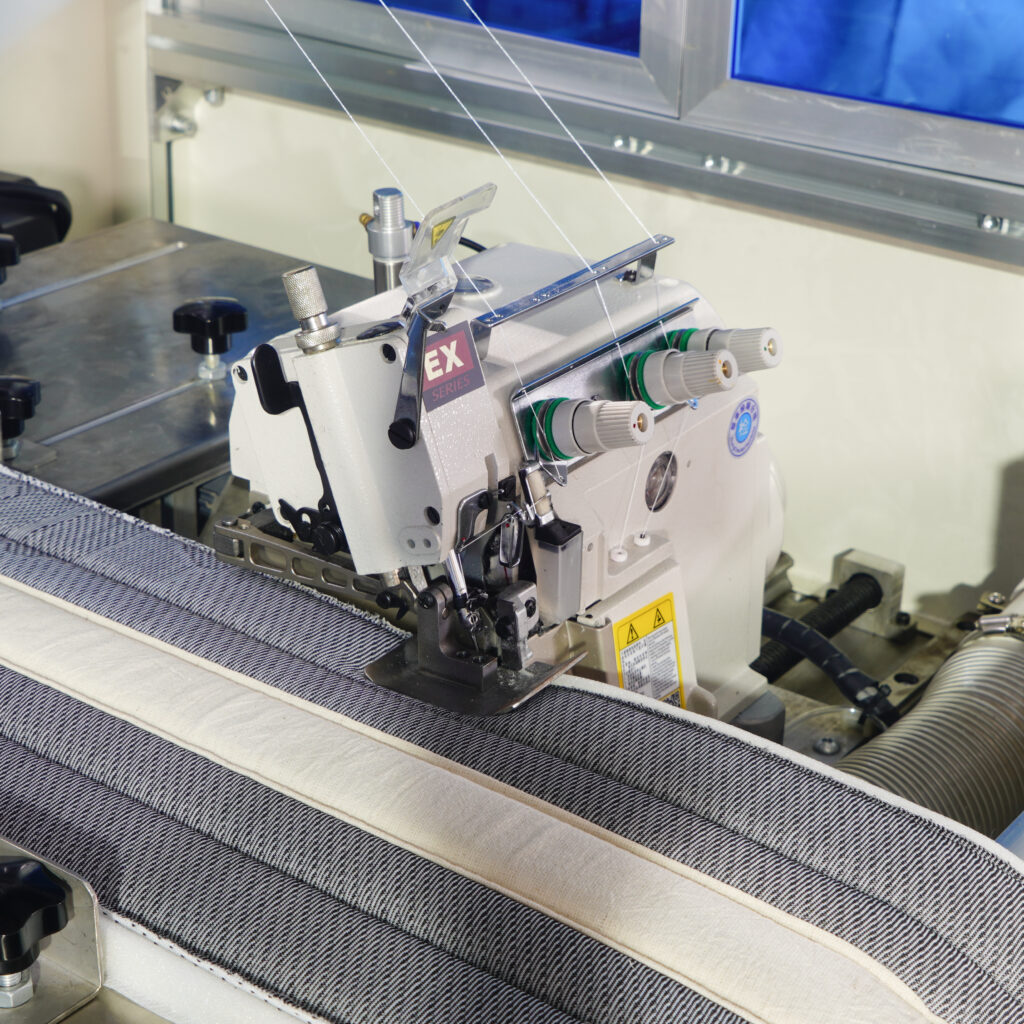

Our Mattress Border Sewing Machines offer advanced, efficient solutions designed for mattress manufacturing. From automatic tape edge machines to semi-automatic border sewing machines.

Our border sewing machine series offers a comprehensive range of solutions for mattress border processing.

Four sewing heads work independently or simultaneously;

ideal for high-precision pattern sewing and decorative

stitching.

Automated & Accurate Quilting for Mattress Panels with Flexible Patterns .

Dual-head operation; high productivity for large-scale

border flanging.

Suitable for straight-line sewing of bone strips, zippers, and trims; multi-functional applications.

Combines sewing and cutting; ideal for continuous production with efficient trimming.

Multi-functional; performs ribbon sewing, bone insertion, and zipper attachment in one process.

Suitable for straight-line sewing of bone strips, zippers, and trims; multi-functional applications.

Combines sewing and cutting; ideal for continuous production with efficient trimming.

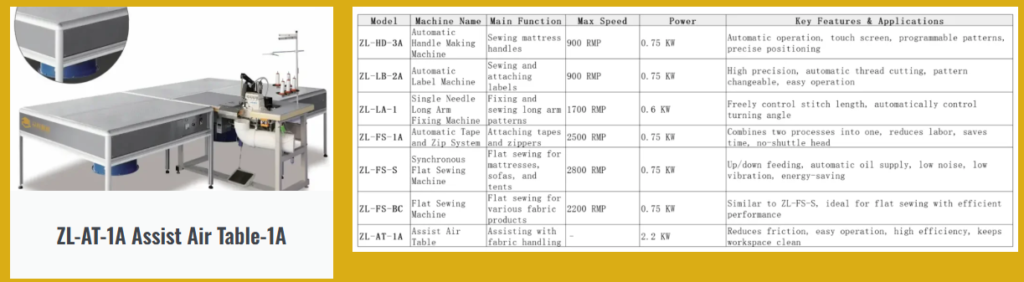

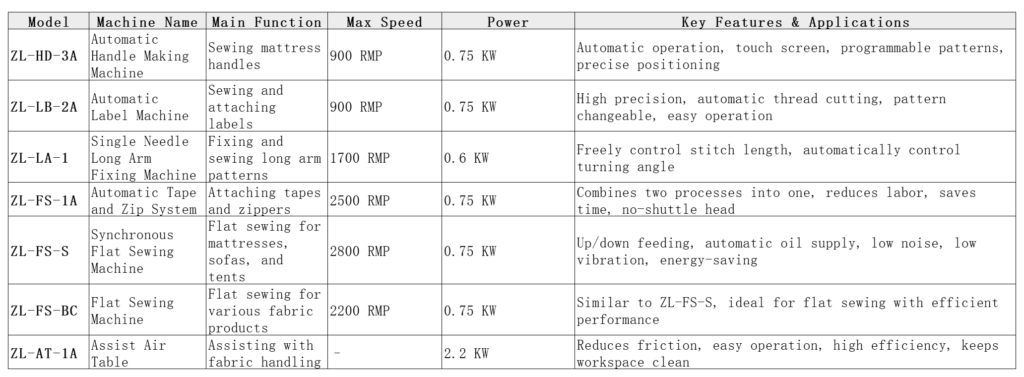

Handle & label sewing: ZL-HD-3A, ZL-LB-2A Tape & zipper application: ZL-FS-1A

Flat sewing applications: ZL-FS-S (high speed), ZL-FS-BC (standard speed) Complex pattern sewing: ZL-LA-1

Fabric handling support: ZL-AT-1A

We are proud to partner with clients worldwide, providing efficient, reliable, and cost-effective mattress and furniture packaging solutions.

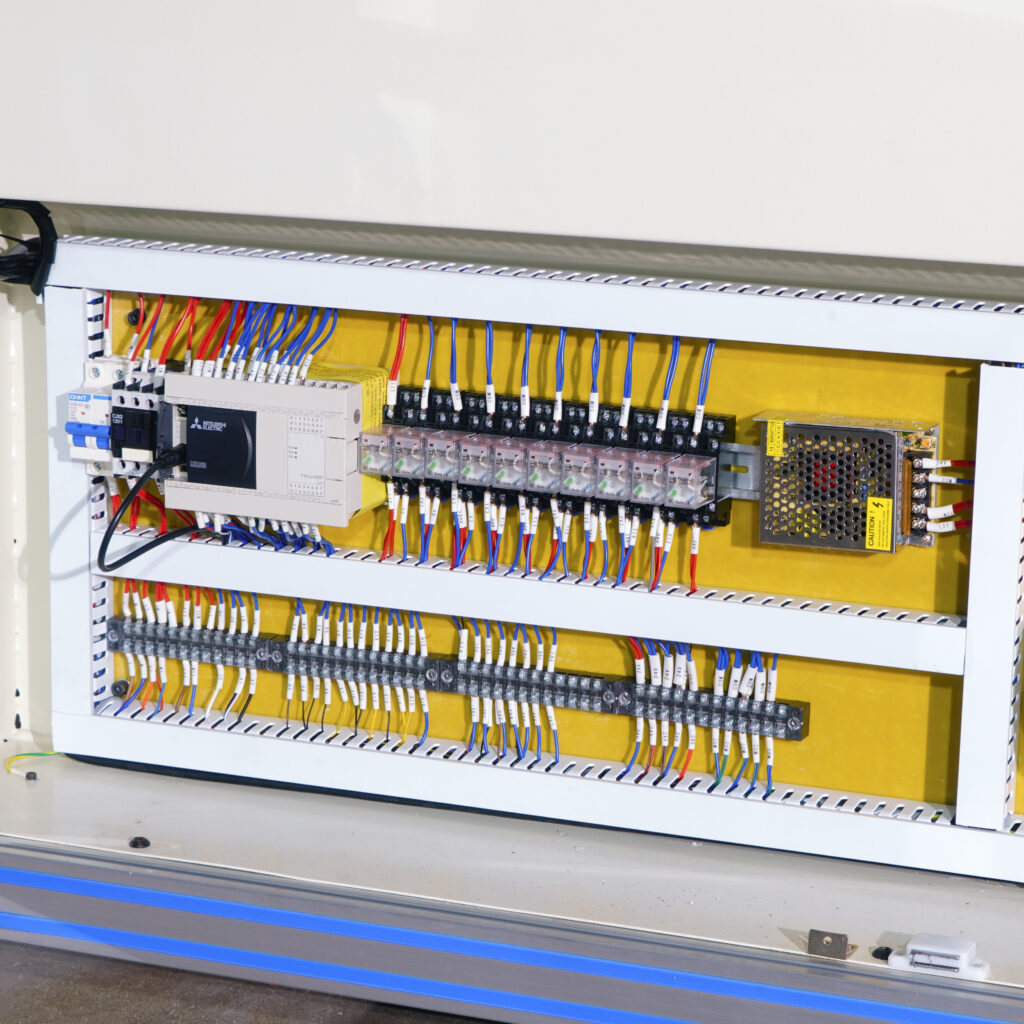

To ensure smooth installation and efficient operation of the mattress sewing machine, please prepare the following materials and installation environment in advance.

Please note that the actual timeline may vary depending on site conditions, preparation adequacy, and logistics. Below is a typical process outline after receiving the mattress sewing machine.

In the mattress industry, the type

How Much Production Capacity Can Ma

Can One Machine Produce Different T

WhatsApp us

Tell us what you need — we’ll handle the rest.