How is a Spring Mattress Made?

Spring mattresses are a popular choice for many sleepers due to their support, comfort, and affordability. But how exactly are these mattresses made? In this article, we’ll dive into the step-by-step process of how a spring mattress is constructed, from material preparation to the final product.

1. Types of Spring Systems Used in Mattresses

Before we get into the production process, it’s important to understand the different types of spring systems used in mattresses. The design and type of spring system can affect the mattress’s firmness, support, and overall feel.

1.1 Innerspring Coil System

The traditional spring system that has been used for decades, featuring a series of interconnected coils that provide consistent support.

1.2 Pocketed Coil System

This type of spring system uses individual coils that are wrapped in fabric. These coils move independently, offering better motion isolation and providing more targeted support.

1.3 Continuous Coil System

In this system, one long piece of wire is used to create a series of connected coils. It offers good durability and consistent support but might not be as flexible as the pocketed coil system.

1.4 Bonnell Coil System

The oldest and most traditional coil design, where coils are connected together to form a grid. This type of spring system is commonly used in budget mattresses.

2. Materials Used in Spring Mattresses

Understanding the materials used is crucial in recognizing the quality and construction of a spring mattress. Each material contributes to the mattress’s comfort, support, and durability.

2.1 Steel Coils

Steel is the primary material used for the coils. The steel used is tempered to ensure durability and support. Different types of steel are used depending on the type of coil system, with higher-quality steel providing better performance.

2.2 Comfort Layers

Foam, memory foam, latex, and fiber padding are placed above the coils to enhance comfort and pressure relief. These materials improve the mattress’s feel and help distribute weight more evenly.

2.3 Mattress Cover and Fabric

The outer fabric can be made from a variety of materials, such as cotton, polyester, or a blend of both. The fabric provides breathability, softness, and durability while protecting the internal components.

3. Manufacturing Process of a Spring Mattress

Now, let’s take a closer look at the step-by-step process of how a spring mattress is made. Each stage is vital in ensuring the final product is high-quality and comfortable.

3.1 Designing the Mattress

The first step in mattress production is designing the mattress. Manufacturers determine the level of firmness, type of spring system, and comfort layers based on market needs and customer preferences. Engineers and designers work together to create a prototype before moving forward with production.

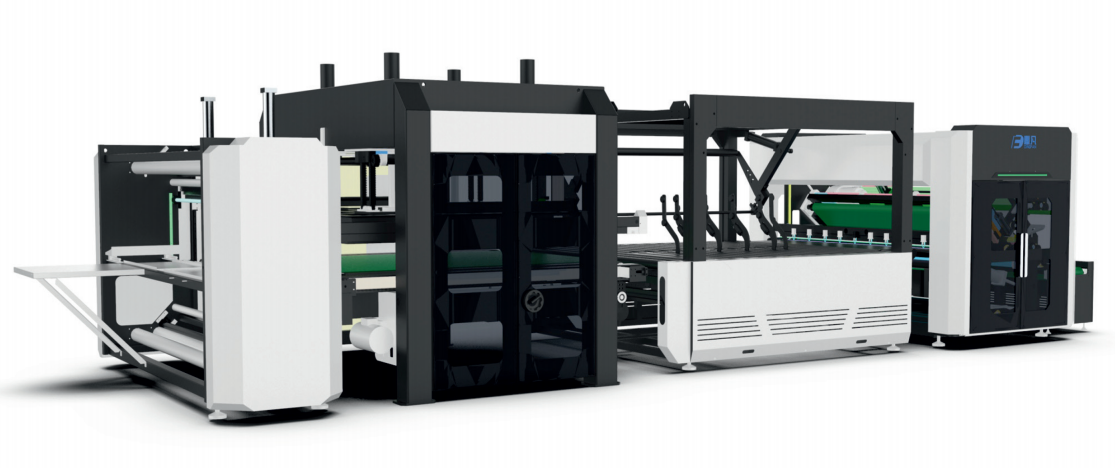

3.2 Creating the Springs

The steel wire is processed into coils using specialized machinery. These coils are then tempered to enhance their strength and durability. The coils are formed into different shapes based on the spring system chosen, whether it’s a traditional innerspring, pocketed, or continuous coil system.

3.3 Assembling the Spring Unit

Once the coils are made, they are assembled into a spring unit. For traditional innerspring mattresses, the coils are interconnected with wire, forming a single framework. For pocketed coil systems, each coil is individually wrapped in fabric to ensure independent movement and minimize motion transfer. These coils are then stitched or fastened together to form the core of the mattress.

3.4 Adding Comfort Layers

After the spring unit is ready, various comfort layers are added on top. These layers can include memory foam, latex foam, and other soft materials that help relieve pressure points and improve comfort. The comfort layers are compressed to fit properly and provide the desired firmness and softness.

3.5 Attaching the Mattress Cover

The mattress cover is the final layer that surrounds the entire mattress. It is usually made from cotton or a cotton blend and is sewn onto the mattress. The cover is often quilted or tufted to secure the internal layers in place and add an extra touch of comfort. The stitching is carefully done to ensure the cover stays in place and doesn’t shift.

4. Quality Control and Testing

Quality control is a crucial part of the manufacturing process to ensure that the mattress meets industry standards. Testing takes place at various stages of production to guarantee durability, support, and comfort.

4.1 Ensuring Consistency and Durability

Manufacturers use testing equipment to measure the mattress’s firmness, support, and durability. The springs are tested for strength and flexibility to ensure they can handle weight without losing their shape. Comfort layers are tested for consistency and pressure relief.

4.2 Safety Standards and Regulations

In addition to performance testing, mattresses must comply with safety standards, such as fire resistance and material certifications. These regulations help ensure that the mattress is safe for use and built to last.

5. Packaging and Shipping

After the mattress passes all quality control tests, it’s ready for packaging and shipment.

5.1 Packaging the Mattress

Most spring mattresses are either compressed or rolled for easier shipping and storage. The mattress is wrapped in a protective plastic cover to keep it clean and safe during transportation. If the mattress is not compressed, it is simply wrapped in plastic and packed for delivery.

5.2 Shipping to Retailers or Customers

Once the mattress is packaged, it is shipped to retailers or directly to customers. Shipping methods vary, but most mattresses are delivered via freight carriers to ensure that they reach their destination in good condition.

6. Conclusion

The production of a spring mattress involves several intricate steps, from material preparation to final packaging. Each stage plays a vital role in ensuring the mattress provides the necessary support and comfort for a good night’s sleep. By understanding the manufacturing process, consumers can make more informed decisions when choosing the right mattress.

Choosing a spring mattress that’s made with high-quality materials and constructed with care can make all the difference in your sleep quality. Whether you’re looking for the classic innerspring design or a more advanced pocket spring system, understanding how your mattress is made ensures that you’re getting the best value for your money.