Are Mattress Spring Machines Compliant with International Safety Standards?

Dangerous machines put workers and production at risk. No manufacturer can afford to ignore safety compliance.

Yes, most mattress spring machines from reputable manufacturers are designed to meet international safety standards such as ISO, CE, and OSHA. These standards help ensure safe machine operation, reduced risk of accidents, and protection for your workforce.

Whether you’re sourcing for export or local production, verifying compliance is critical for long-term business continuity.

What International Safety Standards Apply?

Ignoring international standards is a recipe for fines, downtime, and workplace injuries.

International safety standards define requirements to reduce machinery hazards. Mattress spring machines are expected to comply with several globally recognized systems:

Common Safety Standards

| Standard | Region | Description |

|---|---|---|

| ISO 12100 | Global | General principles for machinery safety, including risk assessment |

| ISO 13849 | Global | Focuses on control system safety and emergency stops |

| CE Marking | European Union | Indicates conformity with EU health, safety, and environmental laws |

| OSHA Standards | United States | U.S. safety regulations, including machine guarding and lockout/tagout |

| CSA Z432 | Canada | Canadian standard for safeguarding machinery |

Compliant machines are typically labeled or certified, and suppliers should provide documentation.

Which Mattress Spring Machines Are Covered?

Every machine on your production floor should meet minimum safety requirements.

The following common machine types all fall under these standards:

-

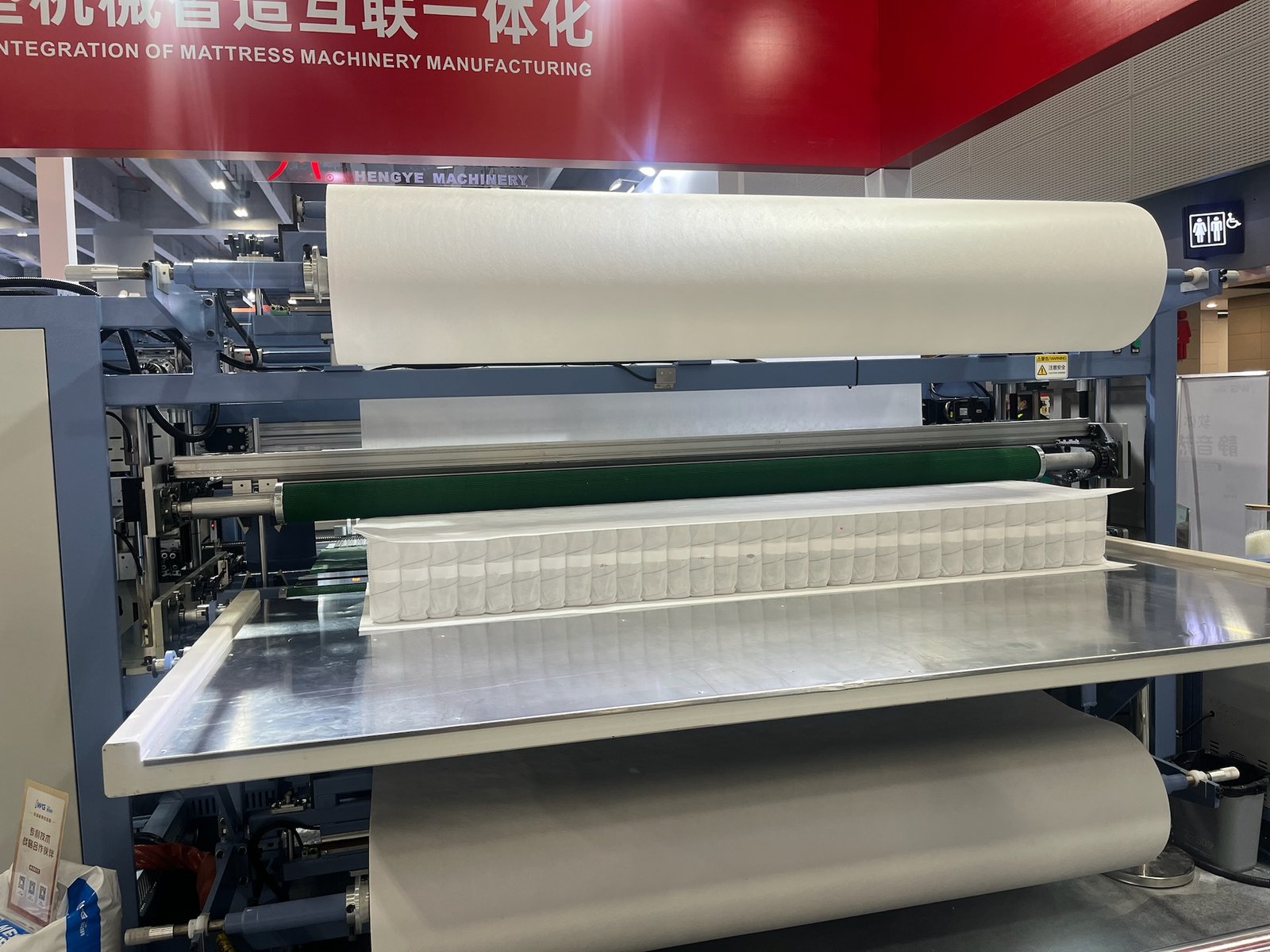

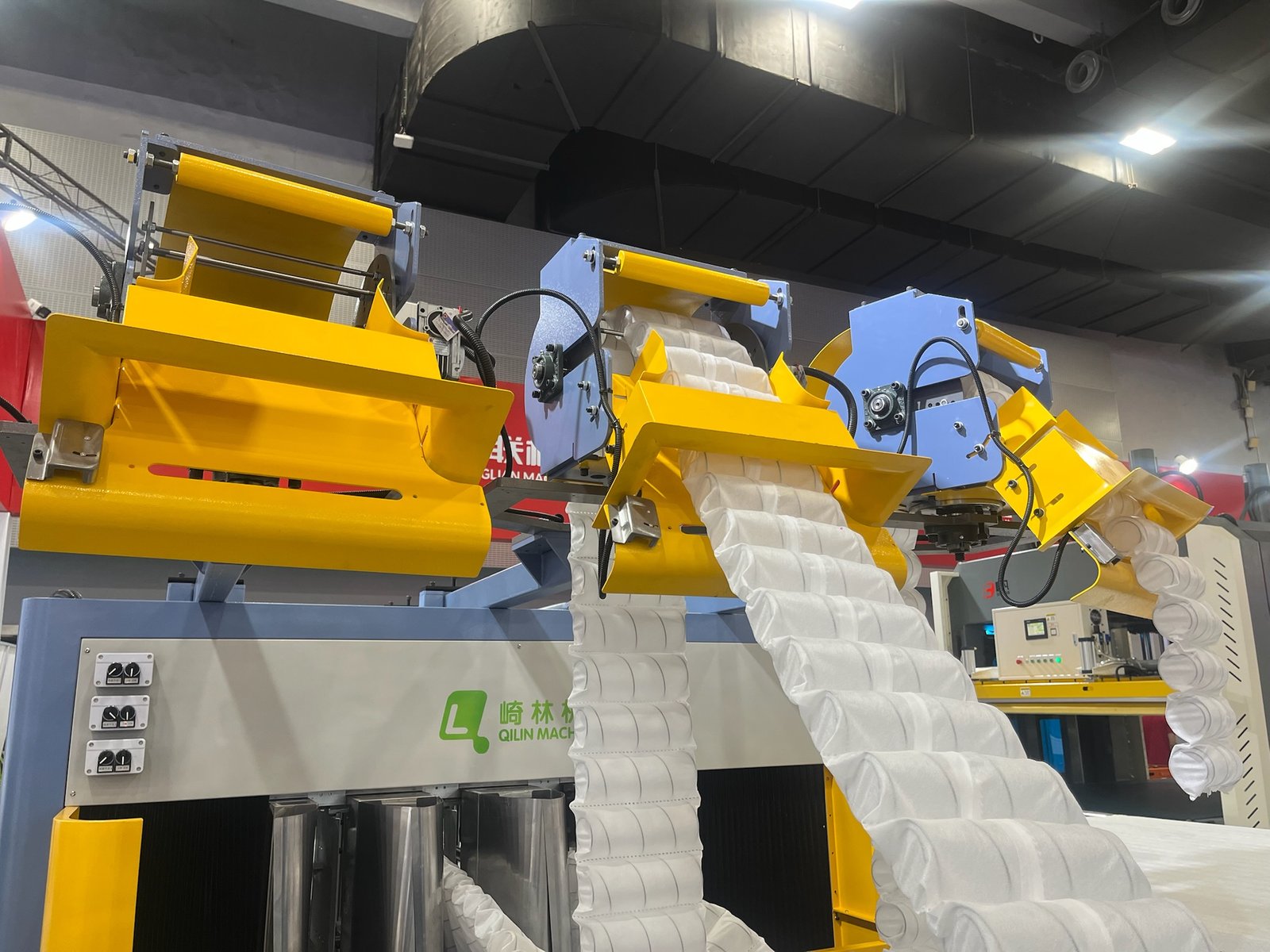

Pocket Spring Machines

- Produces individually wrapped coils.

- Uses high-speed feeding, gluing, and ultrasonic welding.

-

Bonnell Spring Machines

- Shapes hourglass springs and links them with helical wire.

- Involves high-tension wire shaping and forming tools.

-

Continuous Coil Machines

- Forms entire spring rows from one wire strand.

- High wire speed, sharp cutting points, and alignment arms.

Each machine type introduces specific risks, such as pinch points, sharp tooling, or electrical overload.

What Safety Features Must These Machines Have?

To comply with ISO or CE regulations, mattress spring machines must include core safety components.

Standard Safety Features:

| Safety Feature | Function |

|---|---|

| Emergency Stop Buttons | Instantly halts the machine; must be visible and easily accessible |

| Guarding and Enclosures | Prevents access to moving parts, especially during coil forming |

| Interlock Systems | Machine won’t start unless safety gates or guards are correctly closed |

| Fault Detection Sensors | Monitors for misfeeds, jams, or overloads and stops operation if needed |

| Lockout/Tagout Ready | Allows safe maintenance procedures |

| Overload Protection | Prevents damage or injury in case of jams or overpressure |

| Visual Warnings and Labels | Alerts operators to hazardous areas and required PPE |

These features aren’t optional—they’re required for certification.

How Do Manufacturers Verify Safety Compliance?

Don’t assume a machine is safe just because it “looks professional.” Ask for certification.

Typical Compliance Process:

- Design Review and Risk Assessment: Engineers identify mechanical, electrical, and ergonomic risks.

- Documentation and Technical File: Includes schematics, test reports, and control system designs.

- Third-Party Testing (optional): For CE or CSA markings, third-party labs may test machines.

- Self-Certification (common in ISO): For internal compliance, manufacturers may use internal audits.

- Compliance Labels: Machines that pass receive CE labels or equivalent.

📄 Ask for:

- CE Declaration of Conformity

- ISO compliance documentation

- Maintenance and training manuals

What Are the Consequences of Non-Compliance?

Operating a non-compliant machine may seem cheaper—but the risks are massive.

Potential Consequences:

- Injury to operators or maintenance workers

- Machine failure and fire hazards

- Fines or shutdowns by local safety authorities

- Blocked exports in countries requiring CE or CSA compliance

- Legal liability in case of workplace accidents

Even worse, insurance companies may refuse to cover claims involving uncertified machines.

Are There Case Studies of Compliance?

Yes, and the difference in results is clear.

Case 1: Compliant Operation

A European spring mattress producer implemented CE-certified pocket spring machines. With proper guarding, sensors, and lockout systems in place, they recorded zero safety incidents in three years of operation. The machines were also accepted by international buyers with no customs issues.

Case 2: Non-Compliant Import

A Southeast Asian factory purchased low-cost spring machines without CE or ISO certification. Within one year, they faced:

- Two worker injuries due to missing safety covers

- Four unplanned machine breakdowns

- A rejected export shipment to an EU buyer

After these losses, they replaced all non-certified machines with compliant units.

What Role Does Operator Training Play?

Even the safest machine is dangerous if misused.

Training Must Cover:

- Machine startup and shutdown procedures

- Emergency response (use of E-stop)

- Daily inspection checklist

- PPE requirements (gloves, eye protection)

- Lockout/Tagout steps during maintenance

- Recognizing unusual machine behavior

Some manufacturers provide training materials or remote sessions. Others offer on-site setup and walkthroughs for new operators.

What Trends Are Emerging in Safety Compliance?

The future of machinery safety is smart, automatic, and preventive.

Emerging Trends:

| Trend | Description |

|---|---|

| Smart Safety Sensors | Detect abnormal behavior and shut down before failure |

| Predictive Maintenance | AI tracks wear and suggests service before breakdown |

| Wireless Safety Controls | Emergency stops and diagnostics via mobile apps |

| Integrated Training Systems | Machines guide operators with step-by-step instructions |

| Global Harmonization | Machines now meet ISO, CE, and CSA together for easier exports |

Manufacturers who adopt these systems not only stay compliant—they build trust with buyers worldwide.

Conclusion

Mattress spring machines must meet international safety standards to ensure safe operation, protect workers, and maintain global market access. Compliance with ISO, CE, OSHA, and CSA standards is not optional—it’s essential.

When evaluating machinery, always ask for certifications, inspect safety features, and train your team. Safety is not an added feature—it’s part of doing business right.