Heavy-duty mattress production with slow or inconsistent sewing can ruin your efficiency and product quality.

The best mattress sewing machines for industrial use offer high-speed, precise, and durable performance, helping factories produce consistent, long-lasting mattresses.

Choosing the right industrial sewing machine isn’t just about brand—it’s about matching the right specs to your workload, material, and stitching demands. Let’s break it all down.

What Features Define a Great Industrial Mattress Sewing Machine?

When your machine is slow, breaks thread often, or needs daily adjustments—your whole line suffers.

Great industrial mattress sewing machines are fast, strong, easy to use, and built for constant operation.

Core Features to Consider

1. Durability and Build Quality

Industrial use means long shifts, thick materials, and nonstop output. A good machine must be:

- Built with a cast-iron frame or heavy-duty steel housing

- Designed for low vibration and smooth running

- Able to stitch through thick layers like foam + jacquard fabric

2. Speed and Output

You need machines that go 2,000–5,000 stitches per minute without quality drops.

3. Stitch Consistency

Top-tier machines should offer:

- Programmable stitch length and type

- Digital control for tension and foot pressure

- Precision even at high speeds

| Feature | Why It Matters |

|---|---|

| Auto Thread Cutter | Speeds up end-of-seam process |

| Needle Positioner | Cleaner corners and stops |

| Oil Reservoir System | Lower maintenance; smoother long-term running |

What Types of Machines Are Common in Industrial Mattress Production?

Not every stitch on a mattress is the same. From quilting to edge sealing, you need the right tool.

Mattress factories often use 4 core machine types, each built for a specific part of the sewing process.

Most-Used Machine Categories

🧵 Long-Arm Quilting Machines

Used for top and bottom panel stitching. Extended arm allows large quilting patterns.

🪡 Border Sewing Machines

Sew the mattress sides. They handle thick handles, air vents, and branding tape.

🔗 Chainstitch and Lockstitch Machines

Used for internal seams, handles, and pillow-top attachments.

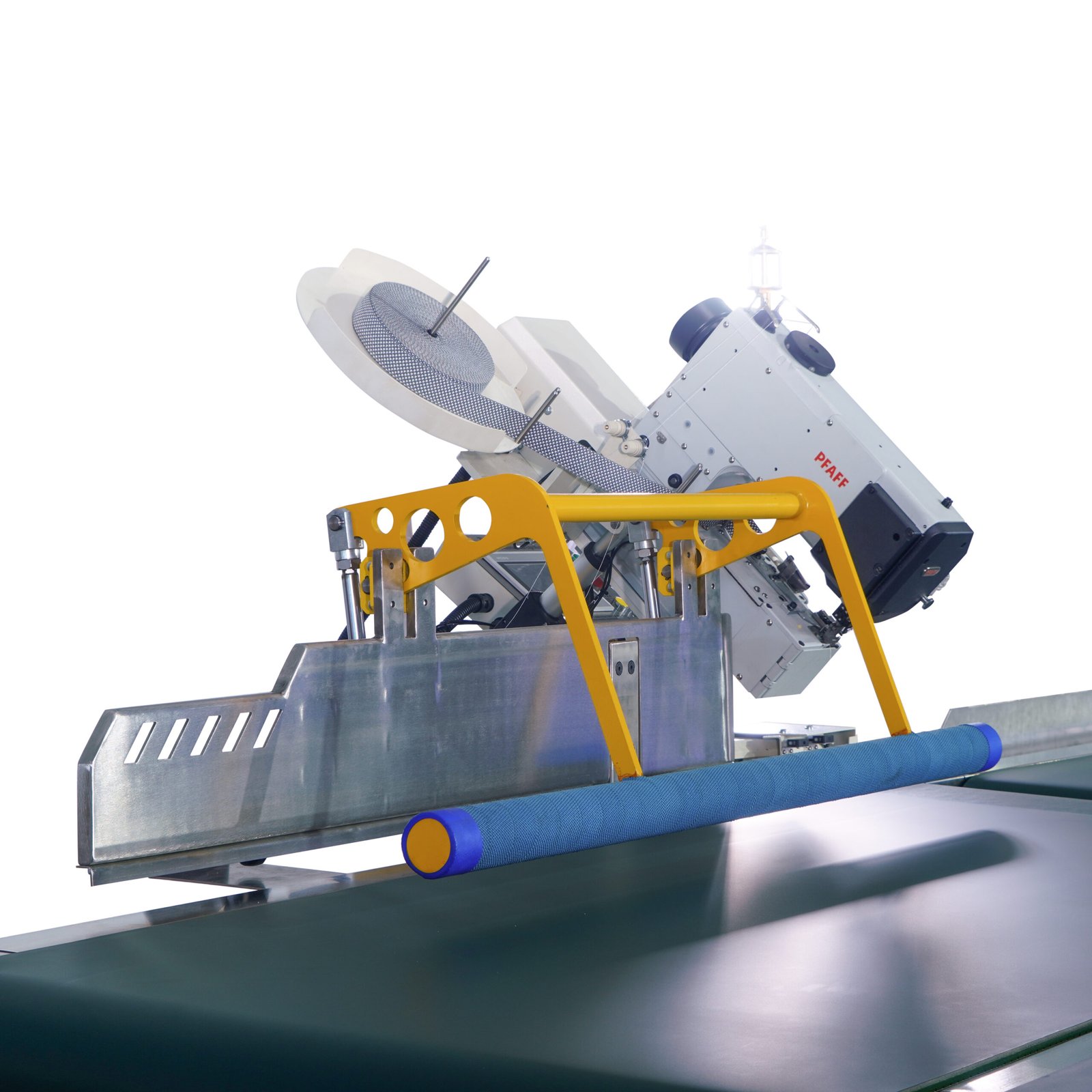

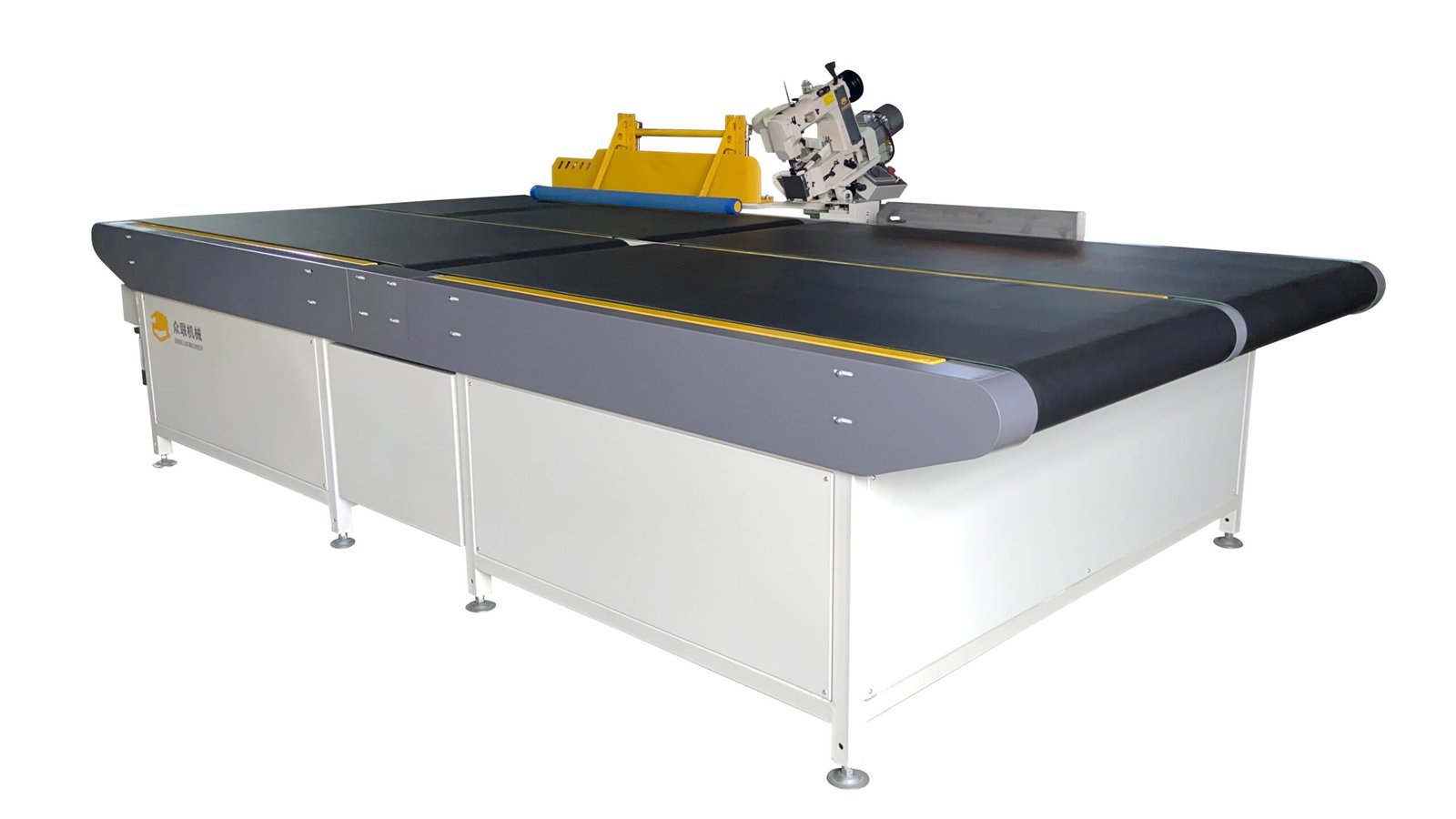

🧶 Tape Edge Machines

Final edge binding machines. They seal the mattress with a clean, tight tape edge.

| Machine Type | Primary Use | Benefit |

|---|---|---|

| Quilting Machine | Top/bottom panel stitching | Decorative + structural function |

| Border Machine | Sides and handles | Durable aesthetics |

| Tape Edge Machine | Final seam sealing | Clean finish, long lifespan |

What Are the Best Brands and Models on the Market?

Going cheap often means paying twice—in downtime and poor stitch quality.

Top brands like JUKI, Brother, and Consew dominate industrial mattress machine markets with proven reliability.

Recommended Models

🔧 JUKI DDL-9000C Series

- High-speed lockstitch

- Dry-head, less oil mess

- Advanced sewing speed control

🧵 Brother S-7300A

- Next-gen digital single needle

- Thread trimming + programmable patterns

- IoT-ready for production line integration

🔨 Consew 206RB-5

- Triple feed walking foot

- Heavy-duty border sewing

- Ideal for thick layers or hard foam/fabric blends

| Model | Stitch Speed | Key Strength |

|---|---|---|

| JUKI DDL-9000C | 5,000 SPM | Speed + stitch consistency |

| Brother S-7300A | 5,000 SPM | Digitized automation |

| Consew 206RB-5 | 3,300 SPM | Strong walking feed system |

How Do These Machines Improve Factory Efficiency?

Switching from semi-industrial to full industrial machines can double your daily output.

Top machines reduce downtime, require fewer operator interventions, and help your factory run more smoothly.

Factory-Level Benefits

- 🔄 Less Thread Breakage → Fewer stops

- 🎛 Digital Presets → Fast changeovers between mattress models

- 🧰 Lower Maintenance → More uptime, less tinkering

| Metric | Semi-Industrial | Industrial-Grade |

|---|---|---|

| Average Output/Day | 80 units | 160+ units |

| Operator per Line | 2–3 | 1 |

| Error/Defect Rate | ~5% | <1.5% |

What’s the Long-Term Cost of Ownership?

Sometimes the best machine is the one that costs more upfront but pays off over time.

A high-end industrial sewing machine often pays for itself in 12–18 months through increased output and lower labor waste.

Consider These Cost Factors

- Machine price (usually $3,000–$12,000)

- Spare part availability and pricing

- Expected daily runtime

- Downtime frequency and fix costs

| Cost Area | Lower-Quality Machine | High-End Machine |

|---|---|---|

| Initial Price | $3,000–5,000 | $6,000–12,000 |

| Downtime/Year | 80–100 hrs | <30 hrs |

| Repairs Needed | Often | Rare |

| ROI Timeline | >24 months | ~12–18 months |

How Easy Are These Machines to Operate?

Your best operators can’t afford to waste time adjusting tension or chasing thread issues.

Top-tier machines come with automated features and ergonomic controls to reduce training time and boost comfort.

Look For:

- Touch screen panels with pattern memory

- Automatic thread trimmers

- Foot-controlled needle lifts

- Digital tension control

These features cut your training time and operator fatigue, especially important for high-volume production shifts.

Conclusion

The best industrial mattress sewing machines balance speed, durability, stitch quality, and ease of use. Choose smart and your line will thank you—with higher output, fewer defects, and more reliable long-term operation.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com