Can Mattress Spring Machines Be Integrated with Other Production Equipment?

Mattress production is evolving—can your machines keep up?

Yes. Modern mattress spring machines can be seamlessly integrated with other equipment, enabling continuous production, reducing labor costs, and improving consistency.

When integrated properly, these machines become the backbone of a smart, automated mattress factory.

Let’s explore how mattress spring machines fit into a production line, the technology behind integration, its benefits, real-world applications, and tips for success.

What Are Mattress Spring Machines and How Do They Work?

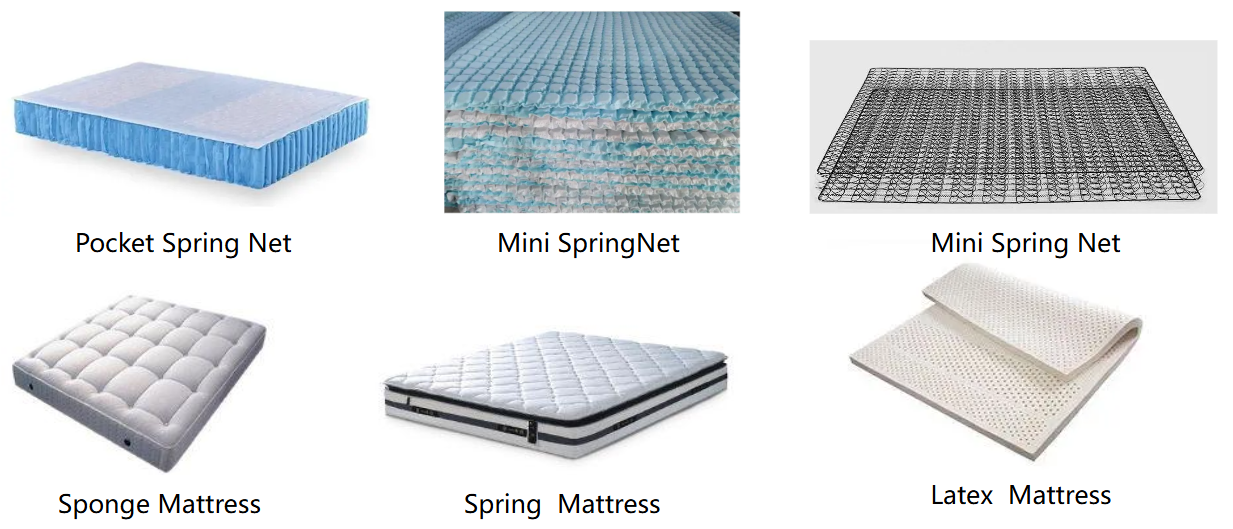

Mattress spring machines form the core structure of innerspring and hybrid mattresses. They come in several types:

- Bonnell Spring Machines: Produce hourglass-shaped springs that are interlinked with helical wires

- Pocket Spring Machines: Coil and insert individual springs into fabric pockets

- Continuous Coil Machines: Shape an endless wire into connected springs

These machines complete tasks like wire coiling, cutting, thermal setting, and sometimes pre-assembly. The resulting spring units are then moved to assembly, padding, and quilting lines.

What’s the Typical Mattress Production Workflow?

A standard mattress factory workflow includes:

- Spring Production: Using coiling or pocket machines

- Spring Unit Assembly: Manual or automated stacking/connection

- Padding & Foam Application: Layers of comfort foam added on top

- Quilting Line: Fabric top panels are stitched and aligned

- Final Assembly: Layers are glued and compressed

- Inspection & Packaging

Spring machines handle stage 1—and integration ensures a smooth flow into later stages.

How Can Spring Machines Be Integrated with Other Equipment?

Modern factories integrate mattress spring machines using smart software, sensors, conveyors, and robotics. Here’s how:

🔄 Automation Interfaces

- Machines communicate via industrial protocols like Modbus, OPC-UA, or Ethernet/IP

- Programmable Logic Controllers (PLCs) synchronize spring output with downstream conveyors

🧠 Central Software Control

- Production software monitors output, controls speed, and logs data

- ERP or MES systems can auto-adjust coil specs based on order queues

🤖 Robotics & Conveyors

- Robots or conveyor belts pick up completed spring units and pass them to foam/glue/quilting lines

- Some pocket spring lines auto-glue and stack spring units with zero manual input

What Are the Benefits of Integration?

| Benefit | Description |

|---|---|

| 💡 Increased Efficiency | Reduce manual handling and idle time between stages |

| 🧼 Consistent Quality | Fewer human errors, better process control |

| 📦 Faster Throughput | Inline production means higher units/hour |

| 💰 Lower Labor Costs | Fewer operators needed per line |

| 📊 Real-Time Visibility | Software tracks output, maintenance needs, and coil specs per order |

Are There Any Challenges?

Yes. Integrating spring machines isn’t plug-and-play. Key considerations include:

1. Software Compatibility

Not all machines speak the same “language.” Older spring machines might not support modern interface protocols. In this case, you may need custom middleware or I/O retrofits.

2. Mechanical Timing

If the spring machine outputs faster than the assembly line can handle, jams or backups occur. Synchronization through sensors and speed controls is critical.

3. Space Constraints

Fully integrated systems require layout planning. Adding conveyors, robots, or buffer stations takes floor space.

4. Customization Limitations

If your production line includes a wide range of mattress types, reconfiguring the integrated line for each variation may be challenging without modular design.

What Kind of Machines Are Easiest to Integrate?

Pocket spring machines with automation-ready PLCs are the most integration-friendly. Many high-end models feature:

- Servo-controlled wire feeders

- Auto-lubrication systems

- Built-in diagnostics

- Network-enabled HMIs (Human Machine Interfaces)

Machines with modular or upgradable design are ideal for phased integration.

Real-World Case Study: Southeast Asia Manufacturer

We helped a Vietnamese factory integrate their twin-line pocket spring machines with auto-glue units and foam rollers. Here’s how it improved performance:

| Before Integration | After Integration |

|---|---|

| Manual spring transfer | Robotic pick-and-place |

| 7 operators per line | 3 operators per line |

| 90 mattresses/day/line | 150 mattresses/day/line |

| Weekly spring jam issues | Auto sync eliminated jams |

ROI was achieved in 11 months.

What Technologies Are Required?

To fully integrate, a spring line may need:

- Servo motors & sensors on output conveyors

- PLCs for spring machines & downstream equipment

- A centralized control cabinet with HMI

- Safety enclosures & emergency stop syncing

- MES or ERP software for live monitoring

Optional add-ons include:

- Barcode/QR scanners for job tracking

- Auto spring defect rejectors

- Glue robots with mattress size recognition

Future Trends in Mattress Line Integration

- AI Monitoring: Systems that learn wear-and-tear patterns to suggest preemptive maintenance

- Cloud Data Sync: All machines report to a central cloud dashboard

- Flexible Production Lines: Easily switch between spring types with minimal downtime

- Collaborative Robots (Cobots): Assist humans with spring stacking, gluing, or flipping

How to Start Integrating Your Line

Here’s a simple phased roadmap:

- Audit your current machines – Check if they support automation interfaces

- Choose a primary integration goal – e.g., speed up transfer from spring to glue station

- Consult with automation integrators or machine suppliers

- Start with pilot integration – One line, basic conveyor, and central control

- Scale up after testing

Integration doesn’t have to happen all at once—start smart, expand over time.

Conclusion

Integrating mattress spring machines with other production equipment is not only possible—it’s the new industry standard. With careful planning and the right technology, you can turn your factory into a seamless, smart production line that boosts efficiency, reduces labor, and delivers consistent product quality.