Small mattress factories struggle with high labor costs, inconsistent quality, and limited production capacity. That’s where mattress spring machines make a real difference.

Even for small-scale operations, mattress spring machines offer lower costs, higher quality, and more output—with minimal floor space and easy operation.

They help small factories compete with larger ones without needing a big team or huge investment.

How Do Mattress Spring Machines Improve Cost Efficiency?

Manual spring production is slow, labor-intensive, and inconsistent. That translates to high costs and lower profits.

Automated spring machines:

- Replace 3–5 manual workers

- Run continuously with low supervision

- Reduce waste and production errors

- Deliver consistent quality every time

Real numbers:

| Expense Category | Manual Setup | Spring Machine Setup |

|---|---|---|

| Labor/month (3–4 staff) | $2,500–$4,000 | $800–$1,200 (1 operator) |

| Daily Output | ~500–800 springs | 6,000–10,000 springs |

| Scrap/Waste Rate | 3–5% | <1% |

| Payback Period | N/A | ~18–24 months |

Even small businesses can recover their machine investment in under 2 years by saving on labor and improving efficiency.

Can Small Factories Maintain Product Quality?

Yes—spring machines actually improve it.

Manual winding and assembling leads to:

- Uneven tension

- Missed welds

- Size inconsistency

Spring machines use servo control and CNC precision to ensure:

- Uniform wire length and coil shape

- Accurate pocket sealing

- Constant tension force

The result: less customer complaints, fewer returns, and more consistent mattress quality across every batch.

What About Production Capacity?

Manual assembly just can’t keep up with rising demand. With a spring machine, even a two-person team can hit large daily targets.

For example:

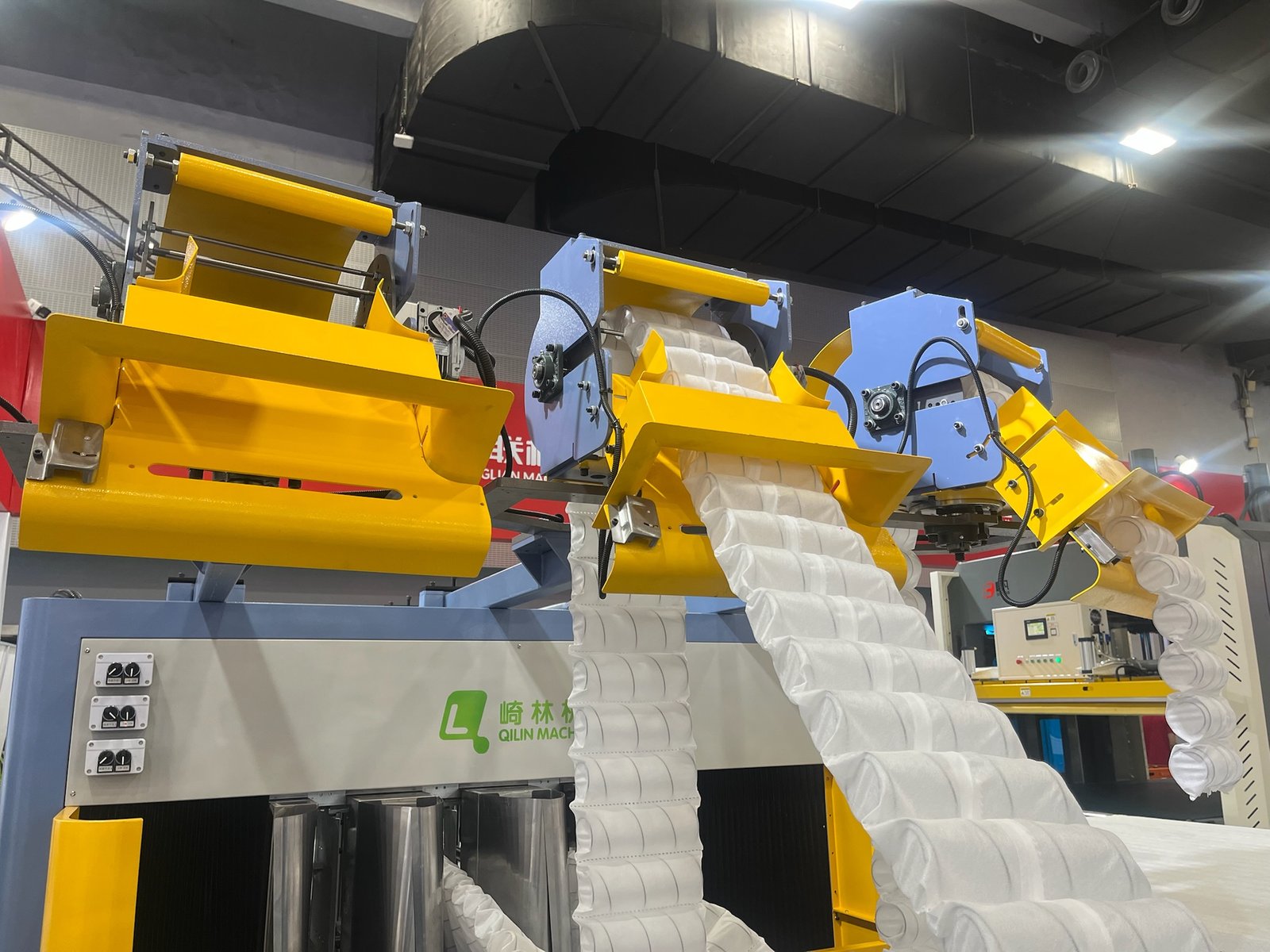

- A QL-80C machine (our double-wire pocket coiler) makes up to 130 springs per minute

- That’s ~8,000 springs per hour

- Enough to produce 20–25 mattress units daily, even in a compact factory

This lets small businesses take on more orders, serve new customers, or reduce delivery time without hiring more people.

Do These Machines Offer Customization?

Yes—and that’s a huge advantage for small brands.

With quick software adjustments, machines can switch:

- Spring height

- Wire thickness

- Pocket fabric color

- Zone layouts (softer middle, firmer edge)

This means you can offer custom mattress solutions—a major edge over mass-produced models from big factories.

Niche Opportunities:

- Firm side / soft side hybrid

- Child or elderly-specific spring units

- Zoned pocket mattresses with different pressure points

- Custom label/private brand units

Small manufacturers can now compete on flexibility and fast turnaround.

What If I Don’t Have a Big Factory?

You don’t need one.

Our spring machines are designed for efficient use of small spaces. A full spring production setup fits in as little as 100–150 square meters.

You can choose:

- Single pocket coiling machine

- Semi-automatic gluing machine

- Manual or motorized spring assembly table

Everything is modular. You can add more automation later as your business grows.

Are These Machines Energy Efficient?

Yes—modern machines are built with energy savings in mind.

Features include:

- Servo motors (lower power, higher torque)

- Idle power-down mode

- Efficient fabric feeding and sealing

- Programmable cycles to avoid overuse

This helps small factories reduce electricity bills—critical for profit margins in markets like Southeast Asia or South America.

What About Maintenance?

Most machines are plug-and-play, with simple interface and low maintenance needs.

We design our models for:

- Easy access to moving parts

- On-screen troubleshooting guides

- Lubrication alerts and auto counters

- Modular parts for quick swaps

Also, our after-sales team offers training and remote support so your operator can handle daily upkeep confidently.

Is Training Provided?

Absolutely. Every machine order includes:

- Hands-on operation training

- Instruction videos

- Digital manuals

- Online troubleshooting support

If you’re in Southeast Asia or the Middle East, we can also send on-site engineers for machine setup and operator coaching.

Your team will learn:

- How to load wire and fabric

- How to change spring specs

- How to clean, calibrate, and reset errors

Even teams with no prior spring experience can learn operation in 1–2 days.

Will This Help Me Compete With Bigger Brands?

Yes—because now you can:

- Make customized, high-quality springs

- Reduce costs and still offer competitive prices

- Deliver orders faster

- Handle both small batches and large retail runs

You don’t need to fight on price alone. You can win with better quality, service, and fast response—powered by automation.

Conclusion

Mattress spring machines are no longer just for big factories. Today’s compact, energy-saving, and user-friendly models are perfect for small manufacturers too.

They save labor, improve quality, and unlock higher capacity—without requiring a large team or facility.