Choosing the wrong machine can waste budget, slow production, and frustrate your team.

The right mattress sewing machine should match your materials, output volume, and technical goals—ensuring quality, speed, and profitability.

There are dozens of machine types out there, but which one truly fits your factory? This article helps you evaluate your real needs, match them to machine specs, and make a smart investment decision.

What Should You Consider Before Choosing a Mattress Sewing Machine?

Too many factories rush to buy the biggest machine on sale—only to regret it months later.

Before choosing a machine, you need to assess your production needs, mattress styles, and the skills of your team.

Understand Your Production Needs

Think about your typical day of production:

- Do you handle foam mattresses, innersprings, or hybrids?

- How many units per shift do you complete?

- Do your clients require custom quilting or uniform, high-speed runs?

Key Pre-Purchase Checklist

| Factor | What to Ask |

|---|---|

| Product Types | Do we produce foam, spring, hybrid, or custom models? |

| Output Volume | Do we need 100/day or 500+/day? |

| Labor Skill Level | Are our workers experienced or entry-level? |

| Stitch Requirements | Do we need simple seams or complex decorative stitching? |

| Space in Factory | Can we accommodate a long-arm or automated machine setup? |

Answering these helps you avoid overspending or buying underpowered machines that can’t keep up.

What Types of Mattress Sewing Machines Are Available?

Buying without knowing the differences can leave you stuck with the wrong tool.

There are three main types: tape edge machines, quilting machines, and border sewing machines—each with a specific role.

Common Machine Types and Uses

1. Tape Edge Machines

These sew the mattress perimeter shut with binding tape. They ensure strong edge closure and a finished look.

2. Quilting Machines

Used for the mattress top and bottom panels. They apply patterns and help fuse comfort layers with ticking fabric.

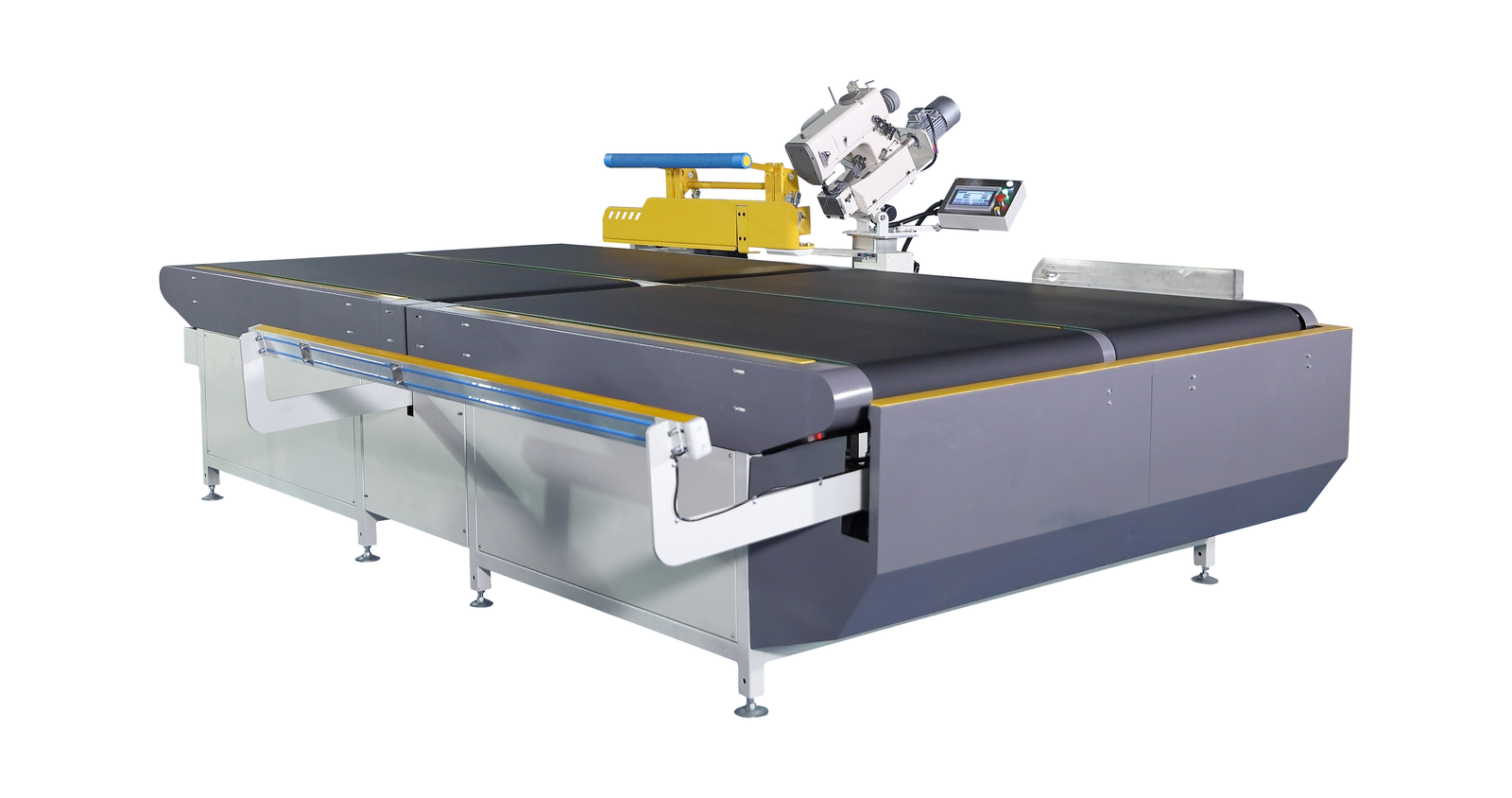

3. Border Sewing Machines

Designed to stitch decorative or structural elements along the mattress sides, usually with heavy fabric.

| Machine Type | Key Use Case | Typical Placement |

|---|---|---|

| Tape Edge | Finish mattress edge | Final assembly stage |

| Quilting Machine | Add quilt pattern to top/bottom panel | Pre-assembly |

| Border Machine | Create stitched border sections | Side-panel preparation |

Some manufacturers also use multi-functional machines, which combine quilting + stitching in one setup.

Which Machine Specifications Actually Matter?

Many buyers get distracted by fancy features they never use.

You should focus on stitching speed, material thickness capacity, pattern flexibility, and power requirements.

Key Specifications to Compare

| Specification | Why It Matters |

|---|---|

| Max Sewing Speed | Impacts daily output (measured in stitches/min) |

| Max Thickness | Determines if the machine can handle dense fabric |

| Stitch Pattern Types | Supports branding/custom requests |

| Thread Compatibility | Different materials require different thread types |

| Motor Type | Servo motors are quieter and more precise |

My Experience

I once sold a basic machine to a client stitching 400gsm quilted fabric. They came back weeks later—it couldn’t handle the density. Now I always check their thickest material before making a recommendation.

How Important Are Durability and Build Quality?

Cheap machines break early—and replacements cost more in the long run.

Durable construction reduces downtime, improves output quality, and protects your ROI.

What to Look For

Materials and Frame

Choose cast iron or steel frame builds. Avoid plastic components.

Internal Parts

Look for quality bearings, belts, and motor brands (like Panasonic, Siemens, etc.)

Design Integrity

Machines with modular parts are easier to repair and upgrade.

| Build Feature | Why It Matters |

|---|---|

| Heavy Frame | Reduces vibration, improves control |

| Reinforced Arm | Withstands thick fabrics |

| Name-Brand Motor | Fewer failures, smoother motion |

A good machine should last 8–10 years with only routine maintenance.

Is Automation and Ease of Use Important?

Your workers don’t need an engineering degree to run a good machine.

Modern machines should offer simple operation, automatic features, and minimal setup time.

Helpful Features

- Auto needle position

- Automatic thread trimming

- Digital stitch selection

- Touchscreen interfaces

- Easy-to-clean thread paths

Training new staff should take less than 3 days. Some brands offer built-in video tutorials or remote support via app.

Machines that are hard to use cause fatigue, increase errors, and delay orders.

What About Price, Support, and Spare Parts?

A machine is only as good as the service behind it.

Beyond specs, evaluate vendor reputation, warranty terms, and spare part availability.

Things to Clarify

- Does the brand offer on-site support or only remote service?

- How quickly can spare parts be delivered to your country?

- Are wear parts (needles, knives, belts) in stock locally?

Pricing Ranges

| Machine Class | Price (USD) | Ideal For |

|---|---|---|

| Entry-Level Manual | $2,000 – $5,000 | Small batch factories |

| Semi-Automatic | $6,000 – $12,000 | Growing mid-volume factories |

| Fully Automatic | $15,000 – $30,000+ | High-output, export factories |

Don’t forget to factor in installation, training, and shipping when budgeting.

Conclusion

The right mattress sewing machine balances power, precision, and ease of use—tailored to your factory’s real needs.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com