Do Manufacturers Provide Training for Operating Mattress Spring Machines?

Do Manufacturers Provide Training for Operating Mattress Spring Machines?

Properly operating mattress spring machines is essential for producing high-quality mattresses. Without training, operators risk damaging the machine, lowering production efficiency, and compromising product quality.

Yes, manufacturers do provide training for operating mattress spring machines. These training programs help operators understand the machinery, master safety protocols, and improve output quality and consistency.

Training ensures machines are used correctly and safely, protecting both people and production.

What Are Mattress Spring Machines?

Without understanding the machines, operators can’t use them efficiently—or safely.

Mattress spring machines are specialized equipment used to produce the internal spring units in mattresses. These springs vary in type and application:

Types of Springs Produced by These Machines:

| Spring Type | Characteristics | Application |

|---|---|---|

| Bonnell Spring | Hourglass shape, connected with helical wire | Traditional firm support |

| Pocket Spring | Individually encased coils | Targeted support, low motion transfer |

| Continuous Coil | One wire forms multiple coils | Durable and consistent support |

| Offset Coil | Hinged design between coils | Contours to the body, ergonomic design |

Each type requires precise machine control and setup. Training helps operators adapt to different spring types and production goals.

Why Is Proper Training Essential?

Without training, production becomes inefficient, error-prone, and even dangerous.

Training provides operators with the skills to handle machines confidently and correctly. Here’s why it’s necessary:

- Efficiency: Trained operators set up and run machines faster.

- Quality Control: They can detect production issues early.

- Machine Longevity: Proper use reduces wear and tear.

- Safety: Reduces accidents caused by misuse or misunderstanding.

Untrained operators can damage the machinery, delay production, or produce defective springs. Manufacturer training addresses all of these risks.

What Do Manufacturer Training Programs Include?

Most mattress spring machine manufacturers offer structured training programs when customers purchase their machines. These programs are often a combination of theory and hands-on practice.

Typical Training Modules Include:

-

Machine Introduction and Setup

- Understanding machine components

- Installing the machine

- Connecting power and calibration

-

Operating Procedures

- Starting and stopping the machine

- Feeding wire and loading materials

- Adjusting coil diameter, spring height, and tension

-

Troubleshooting

- Detecting jammed wire, misaligned coils, or machine faults

- Using error codes and built-in diagnostics

-

Maintenance Basics

- Daily checks and lubrication

- Replacing wear parts

- Keeping software and firmware up to date

-

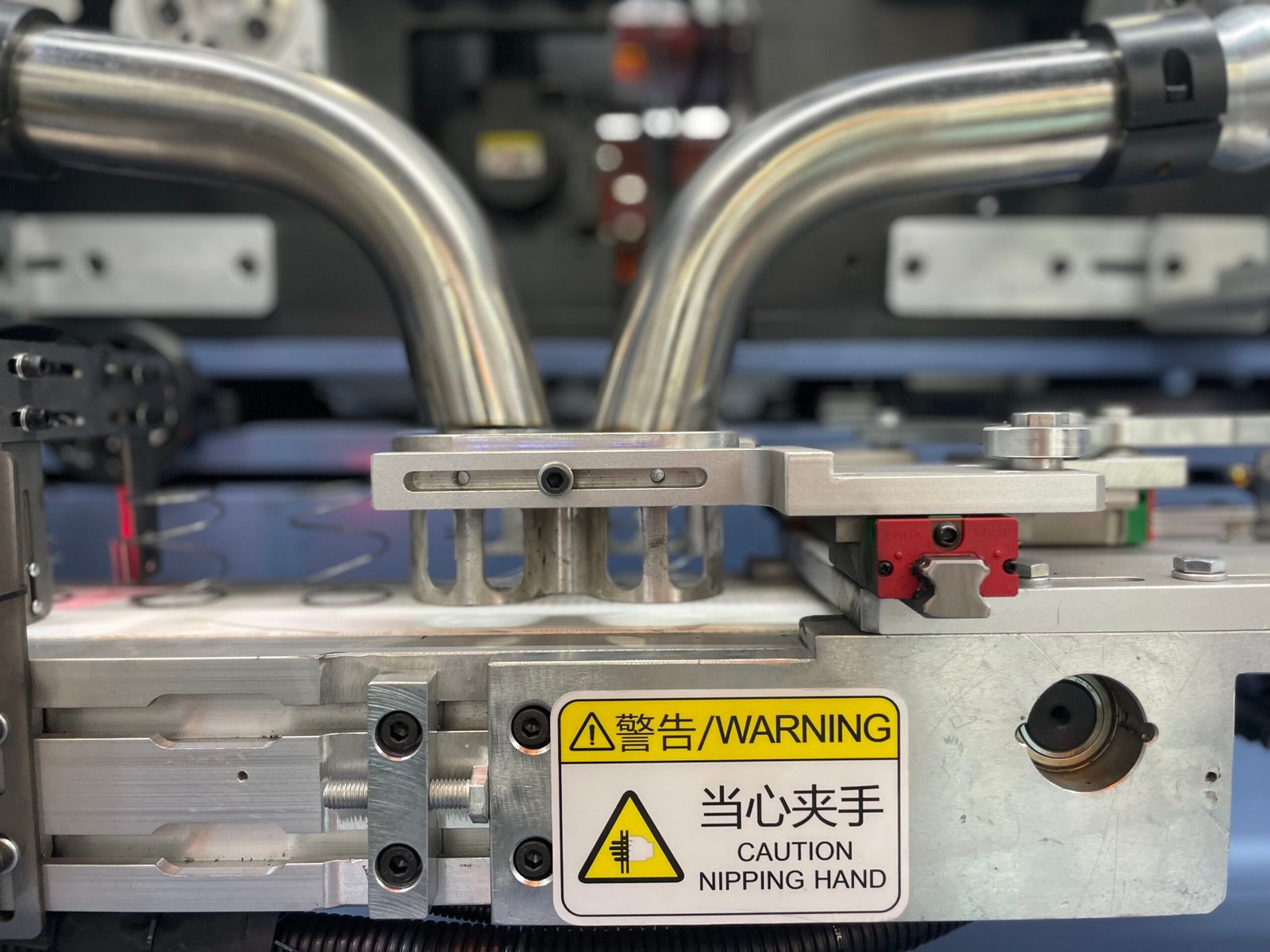

Safety and Emergency Protocols

- Using emergency stops

- Avoiding pinch points and moving parts

- Handling tools and sharp materials

-

Spring Quality Checks

- Measuring spring dimensions

- Spot-checking spring consistency

- Testing finished spring units

These modules help the operator build a full picture of how to use the machine effectively.

How Long Does the Training Take?

The training length depends on the machine’s complexity and the operator’s previous experience. Here’s a general breakdown:

| Training Type | Duration | Focus Areas |

|---|---|---|

| Basic Setup and Operation | 1–3 Days | Loading materials, machine start/stop, basic safety |

| Full Production Training | 1–2 Weeks | Troubleshooting, calibration, coil quality assessment |

| Advanced Maintenance | Up to 1 Month | Diagnostics, software updates, modular part replacement |

Manufacturers often customize the training schedule to fit the production pace and operator availability.

Is Certification Included?

Many manufacturers issue a certificate upon completion of training. This helps employers:

- Identify skilled machine operators

- Assign qualified staff to complex production lines

- Track who is authorized to handle specific equipment

Some certifications may include a written test or practical assessment. This ensures the operator is ready to run the machine independently.

On-the-Job vs. Formal Manufacturer Training

Some factories rely on senior workers to train new employees. While helpful, this informal approach has limits:

| Comparison | On-the-Job Training | Manufacturer Training |

|---|---|---|

| Structure | Often inconsistent | Structured and comprehensive |

| Speed | Faster, but risk of skipping details | Slower, more thorough |

| Risk of Errors | Higher due to gaps in knowledge | Lower thanks to tested protocols |

| Documentation | Rarely tracked | Usually comes with manuals and logs |

For high-value machinery like spring machines, formal training offers better results and safety.

Do Manufacturers Provide Refresher Training?

Yes. Many manufacturers offer:

- Online modules for software updates

- On-site visits for new staff training

- Remote troubleshooting sessions for real-time support

Refresher courses help teams stay sharp as machines evolve or as new spring types are introduced.

Conclusion

Proper training from the manufacturer is essential for operating mattress spring machines safely and efficiently. These machines are not plug-and-play—they require precision, routine care, and a deep understanding of their operation.

Manufacturer-provided training ensures operators know how to use the machine, prevent errors, maintain safety, and produce high-quality springs consistently.