The mattress industry is evolving fast—hybrids, memory foam combos, sustainability trends. Machines that can’t adapt? They’re out.

Modern mattress spring machines adapt through multi-format flexibility, automation upgrades, and real-time data controls to meet shifting consumer and market needs.

If you’re in mattress production, your machines must evolve as fast as the market. Here’s how.

What’s Driving the Shift in Market Demand?

Demand is no longer one-size-fits-all.

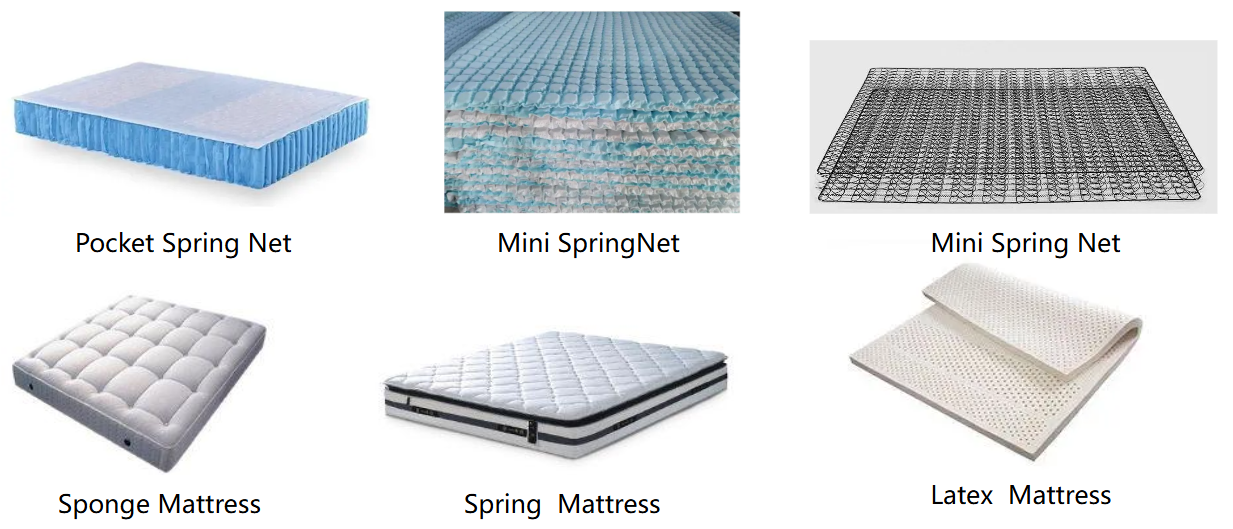

Consumers today want personalization, eco-friendliness, and hybrid comfort. That means manufacturers need machines that can shift between multiple spring formats quickly.

Three main trends driving this:

| Trend | Machine Impact |

|---|---|

| Hybrid mattresses | Need to run pocket + bonnell springs |

| Fast delivery expectations | Shorter production cycles |

| Eco-conscious consumers | Lower waste, more sustainable materials |

Machines must now be versatile, fast, and environmentally efficient—without compromising on coil precision.

How Is Technology Upgrading These Machines?

We’re not in the 90s anymore.

Modern mattress spring machines are powered by PLCs, sensors, and AI-based diagnostics. What used to take hours now happens in minutes—with fewer hands involved.

Key Tech Features:

- CNC spring coiling: Automated control over wire feed, pitch, and diameter

- Servo-driven axes: Enable fast adjustment for coil count, height, and gauge

- Real-time defect detection: Cameras and sensors catch misalignments instantly

- Cloud integration: Production data syncs directly with ERP systems

These upgrades allow for adaptive production—changeover from one spring spec to another can happen in under 10 minutes.

Can Machines Really Handle Customization?

Yes—and it’s non-negotiable now.

We get more requests for ‘zoned’ spring setups or mixed coils per mattress. A flexible machine lets us program exact spring counts, coil tensions, and even row spacing on the fly.

What we customize:

- Wire gauge: 1.3–2.3mm

- Coil height: 8–20cm

- Zones: lumbar support, edge reinforcement

- Row format: 3, 4, 6 or custom layouts

Without this flexibility, you can’t serve today’s market.

What About Speed and Throughput?

Speed is still king.

New-gen machines deliver up to 120 springs per minute—with automatic bagging, gluing, and roll-up options.

That means:

- Fewer operators per line

- Lower per-unit cost

- Higher scalability

The fastest producers win bulk contracts. If your machines can’t keep up, you’ll lose them.

How Is Quality Control Being Automated?

Every coil counts—literally.

Spring machines now have inline inspection systems. These monitor:

- Coil diameter deviation

- Missing turns

- Improper pitch

- Tension inconsistencies

When errors are spotted, the machine flags the defect and halts production or removes the coil automatically.

We also use SPC dashboards to track defect rates across shifts. That data helps us improve training, maintenance, and scheduling.

Are Today’s Machines Sustainable?

They have to be.

Energy efficiency and material waste reduction are now top buying criteria. New machines offer:

| Feature | Sustainability Impact |

|---|---|

| Power-saving motors | Up to 30% energy reduction |

| Coil length optimization | Minimizes cut-off wire waste |

| Recyclable components | Lowers machine end-of-life disposal impact |

Some models even run recycled steel wire with no quality loss—perfect for ESG-conscious manufacturers.

How Do They Integrate With the Supply Chain?

It’s not just about production anymore.

Smart mattress spring machines now sync with your inventory and planning software.

You can:

- Track output in real-time

- Predict coil usage for each SKU

- Schedule preventive maintenance to avoid downtime

- Auto-reorder wire rolls or spring bags

That means you spend less time chasing numbers—and more time fulfilling orders.

How Do We Train Operators on All This?

New machines need skilled operators, but training has gotten smarter too.

We now train through:

- Touchscreen tutorials built into the machine

- Simulation modes for new staff

- QR code–linked manuals at each station

- Remote diagnostics via mobile apps

It takes about 2–3 days to get a new operator productive on modern systems.

What’s Coming Next?

Here’s what we see on the horizon:

- AI-based predictive coiling: Machines that adjust in real-time based on mattress type

- Voice-activated controls: For hands-free adjustments

- Modular coil types: Produce multiple spring styles from the same base machine

- Carbon-tracking dashboards: See emissions per batch in real time

The next-gen mattress spring machine will do more than coil wire—it’ll manage your factory flow.

Conclusion

Adaptable mattress spring machines aren’t a luxury anymore—they’re a requirement. If your equipment can’t respond to fast-changing specs, materials, or markets, it will hold you back.

Today’s machines are smarter, faster, more flexible—and they’re changing how we meet tomorrow’s demand.