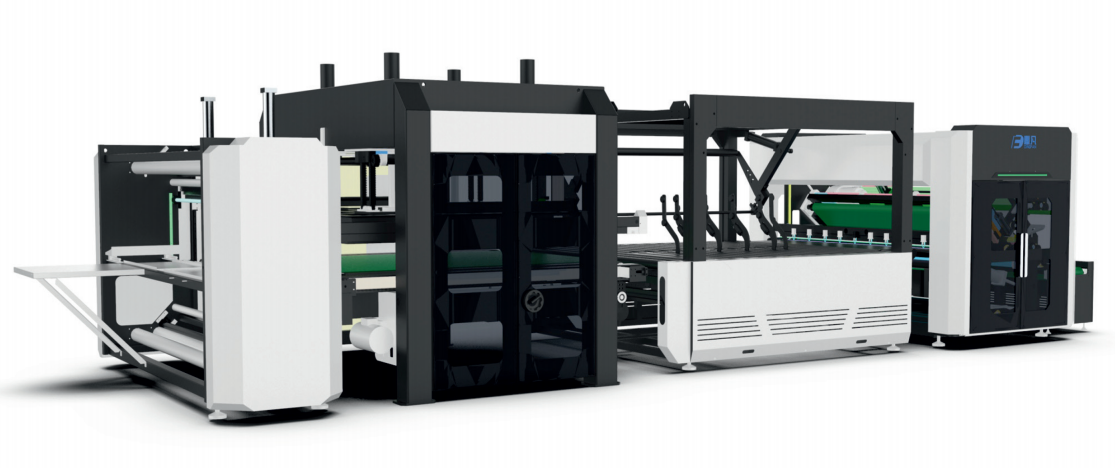

How Does the Mattress Packing Machine Help Your Business?

Mattress manufacturers are constantly looking for ways to improve efficiency, reduce costs, and optimize their operations. A mattress packing machine is a game-changer in this industry, helping businesses streamline production, minimize storage and transportation expenses, and enhance product quality. But how exactly does it benefit your business? Let’s dive in.

Improved Efficiency and Production Speed

One of the biggest advantages of using a mattress packing machine is the significant improvement in production speed. Traditional mattress packaging methods are labor-intensive, time-consuming, and prone to inconsistencies. A mattress packing machine automates the entire process, ensuring faster and more precise packing.

Key Benefits:

- Automates compression, rolling, and sealing in one step.

- Reduces the need for manual labor, cutting down on labor costs.

- Increases the number of mattresses packaged per hour, boosting productivity.

- Minimizes human error, ensuring consistent packaging quality.

By integrating a mattress packing machine into your production line, you can scale up production and meet growing customer demands efficiently.

Cost Savings and Operational Optimization

Cutting operational costs is a priority for any business. A mattress packing machine helps in multiple ways:

| Cost Factor | Savings with a Mattress Packing Machine |

|---|---|

| Labor Costs | Requires fewer workers to operate, reducing payroll expenses. |

| Material Waste | Optimizes packaging materials, minimizing excess use. |

| Shipping Costs | Reduces mattress size for transport, lowering freight charges. |

| Storage Costs | Compressed mattresses take up less space, saving warehouse expenses. |

Investing in an automated packing system leads to long-term savings and improved profit margins, making it a smart business decision.

Space Optimization in Storage and Transport

Compressed and vacuum-sealed mattresses take up significantly less space compared to traditionally packaged ones. This allows businesses to store and transport more products in the same amount of space, reducing overall logistics costs.

Advantages of Compact Packaging:

- Storage Efficiency: More mattresses can be stored in warehouses, freeing up space for additional inventory.

- Lower Shipping Costs: Compressed mattresses reduce freight costs, allowing businesses to maximize shipping container capacity.

- Easier Handling: Rolled mattresses are easier to move, stack, and transport, improving logistics efficiency.

For manufacturers looking to expand distribution while controlling logistics expenses, a mattress packing machine is a must-have.

Enhanced Product Protection

Ensuring product integrity during storage and shipping is crucial. Poorly packaged mattresses are prone to dirt, moisture, and damage, leading to returns and customer dissatisfaction.

How Mattress Packing Machines Enhance Protection:

- Vacuum sealing prevents exposure to dust, dirt, and allergens.

- Plastic film wrapping adds an extra layer of protection against moisture and humidity.

- Consistent compression ensures the mattress maintains its shape and quality.

This level of protection increases customer satisfaction and reduces product returns, benefiting both manufacturers and retailers.

Compatibility with Different Mattress Types

Mattress packing machines are designed to accommodate various mattress types, including:

| Mattress Type | Suitability for Compression Packing |

|---|---|

| Memory Foam | ✅ Highly suitable, compresses easily. |

| Latex | ✅ Can be compressed but requires careful handling. |

| Hybrid | ✅ Compatible, but spring components need extra consideration. |

| Innerspring | ⚠️ Less ideal, but possible with proper settings. |

Manufacturers producing different mattress models can adjust machine settings to ensure proper compression and packaging for each type.

Features to Look for in a Mattress Packing Machine

Choosing the right mattress packing machine for your business depends on several factors. Here are some essential features to consider:

Automation and Smart Controls

- PLC control systems with touchscreen interfaces for easy operation.

- Automated sealing and rolling to minimize manual labor.

- Adjustable settings for different mattress sizes and thicknesses.

Speed and Customization Options

- Fast compression cycles to maximize output.

- Customizable roll sizes to meet specific shipping and storage needs.

- Integration with existing production lines for seamless workflow.

Durability and Maintenance

- Heavy-duty steel construction for long-term use.

- Low maintenance design with easily replaceable parts.

- Reliable after-sales support from the manufacturer.

Real-World Applications and Success Stories

Many mattress manufacturers have successfully adopted automated packing solutions to streamline operations. Here are some real-world benefits:

- A mid-sized mattress factory reduced labor costs by 30% after implementing an automated packing system.

- A direct-to-consumer mattress brand increased shipping efficiency, allowing them to cut freight expenses by 40%.

- An international exporter improved packaging consistency, reducing product returns due to transit damage.

These success stories highlight how a mattress packing machine can transform business operations.

How to Choose the Right Mattress Packing Machine

Before purchasing a mattress packing machine, consider these factors:

- Production Scale – Small businesses may need semi-automatic machines, while large manufacturers require fully automated systems.

- Mattress Compatibility – Ensure the machine supports your product range (memory foam, hybrid, latex, etc.).

- Budget & ROI – Evaluate upfront costs against long-term savings and operational benefits.

- Manufacturer Support – Choose a reputable supplier with reliable customer service and spare part availability.

Conclusion

A mattress packing machine is a powerful tool for businesses looking to enhance efficiency, reduce costs, and optimize storage and transportation. By investing in the right machine, manufacturers can increase production speed, protect their products, and improve overall profitability.

For businesses aiming to stay competitive in the mattress industry, automation is no longer a luxury—it’s a necessity.