Understanding the Basics of Mattress Spring Machines

Introduction

Mattress spring machines are crucial for producing various types of springs, such as Bonnell, pocket, and continuous springs, which are essential to providing comfort and support in mattresses. Understanding the fundamentals of these machines—how they are set up, the user interface, training requirements, safety features, maintenance routines, and more—can help manufacturers optimize production and improve overall efficiency. This article explores these aspects in detail, offering practical insights for anyone involved in mattress production.

1. Understanding the Basics of Mattress Spring Machines

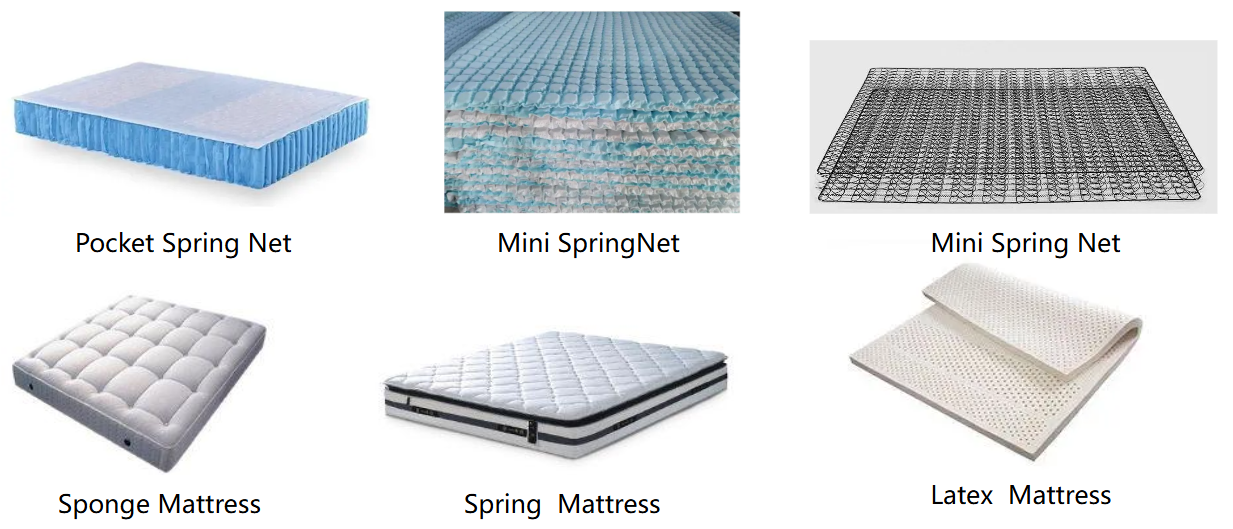

Mattress spring machines are specialized equipment designed to produce the springs that form the core support system of a mattress. The springs are critical to ensuring the mattress provides proper support and comfort to the sleeper. These machines are capable of producing several types of springs, each with its unique characteristics:

- Bonnell Springs: These are traditional hourglass-shaped springs, interconnected to form a stable and supportive core. Bonnell springs are durable and commonly used in budget-friendly mattresses.

- Pocket Springs: These individually wrapped springs move independently, offering better motion isolation and tailored support. They are popular in high-end mattresses for their ability to reduce motion transfer and improve comfort.

- Continuous Springs: Made from a single piece of wire, continuous springs provide consistent support and durability. They are often used in mid-range mattresses for their uniform support.

The primary function of mattress spring machines is to automate the production process, ensuring consistent quality, efficiency, and high-output results.

2. Initial Setup and Calibration

Proper initial setup and calibration are critical to ensuring that mattress spring machines operate at optimal efficiency. The setup process involves:

- Installation: The machine must be installed correctly, ensuring all components are assembled, connected to the appropriate power sources, and in proper working order.

- Calibration: Accurate calibration of the machine is essential for producing springs of the correct size and shape. Operators adjust parameters such as wire tension, spring diameter, and coil pitch to ensure precision. Calibration ensures that all springs meet specific production standards.

- Testing: After calibration, test runs are performed to verify the machine’s functionality. This helps detect potential issues and ensures that the machine is fully optimized for production.

Proper setup and calibration minimize defects and improve overall efficiency by preventing costly mistakes during production.

3. User Interface and Controls

Modern mattress spring machines come equipped with user-friendly interfaces that enhance productivity and simplify operations. These interfaces typically feature:

- Control Panels: These panels include buttons, switches, and touchscreens that allow operators to easily manage machine functions. The controls are designed to be intuitive, enabling operators to quickly become proficient in using the machine.

- Display Screens: These screens provide real-time data on the machine’s status, such as production speed, spring dimensions, and error messages. This helps operators monitor and adjust the machine for optimal performance.

- Software: Many machines are equipped with specialized software that allows operators to program and control the machine, store calibration settings, and troubleshoot issues. The software enhances the overall efficiency of the machine, streamlining production.

The ease of use provided by these interfaces ensures smooth operations, reduces errors, and enhances overall productivity.

4. Training Requirements

Operating mattress spring machines requires a certain level of expertise. Manufacturers typically provide training programs to ensure operators are proficient in machine operation. Training includes:

- Basic Operation: Operators are trained in essential tasks such as machine setup, calibration, and managing the production process.

- Safety Protocols: Safety training is crucial to ensure operators understand emergency stop procedures, proper handling of materials, and the importance of safety guards and protective equipment.

- Advanced Skills: For complex machines, operators may need specialized knowledge, including troubleshooting techniques and software programming.

Certification may be required to ensure operators are fully trained and capable of maintaining safety and efficiency on the production floor.

5. Safety Features and Protocols

Safety is a top priority when operating mattress spring machines. These machines come equipped with several features to protect workers and ensure smooth operation:

- Emergency Stop Buttons: These buttons allow operators to immediately stop the machine in case of an emergency, preventing accidents and minimizing potential damage.

- Safety Guards: Guards are in place to shield operators from moving parts and other hazards. These ensure that workers are not exposed to unnecessary risks.

- Safety Protocols: Operators must follow established safety procedures, which include wearing appropriate protective gear, keeping work areas clean, and undergoing regular safety training. Adherence to safety protocols helps minimize the chance of workplace accidents.

By integrating these safety features, manufacturers can foster a safe working environment and reduce the likelihood of operator injury or machine damage.

6. Maintenance and Troubleshooting

Ongoing maintenance is critical to keeping mattress spring machines in optimal condition. Regular maintenance includes:

- Cleaning: Regular cleaning of the machine components ensures smooth operation and prevents buildup that can impair machine performance.

- Lubrication: Proper lubrication of moving parts minimizes friction and wear, extending the life of the machine.

- Inspection and Replacement: Operators should routinely inspect parts for signs of wear or damage and replace components as needed to prevent breakdowns.

Troubleshooting is also an essential skill for operators. Common issues like wire jams, coil misalignments, or software errors must be addressed promptly to minimize downtime and maintain production efficiency. Effective maintenance and troubleshooting practices contribute to the machine’s longevity and reliability.

7. Efficiency and Productivity

The efficiency of mattress spring machines is influenced by various factors, including machine settings, operator skill, and maintenance practices. Easy-to-use interfaces and automated functions contribute to increased productivity by reducing the need for manual interventions. Regular maintenance and precise calibration are also key to ensuring consistent, high-quality spring production. Skilled operators can optimize machine performance, minimize waste, and keep production lines running smoothly. High efficiency and productivity lead to increased output, improved product quality, and reduced operational costs.

8. Cost of Operation

Operating mattress spring machines involves several costs, including:

- Energy Consumption: These machines require substantial power to operate, and energy costs can add up over time. Efficient machines and regular maintenance help minimize energy consumption.

- Maintenance Costs: Regular maintenance ensures the longevity of the equipment, but it also comes with ongoing costs for parts, labor, and inspections.

- Operator Training: Training programs are essential to ensure operators are fully skilled, but they represent an upfront cost for manufacturers.

While the initial cost of the machines and ongoing operational expenses can be high, the ability to produce large volumes of high-quality springs efficiently can lead to significant cost savings in the long run.

Conclusion

Understanding the basics of mattress spring machines, from their setup and calibration to safety features, maintenance routines, and productivity, is vital for manufacturers looking to optimize production. Proper machine operation ensures high-quality spring production, efficient use of resources, and safe working conditions. By investing in training, maintenance, and the right machinery, manufacturers can achieve higher productivity and maintain a competitive edge in the mattress manufacturing industry.