How Energy-Efficient Are Modern Mattress Spring Machines?

How Energy-Efficient Are Modern Mattress Spring Machines?

Increased energy costs and environmental concerns are forcing mattress factories to rethink every kilowatt.

Modern mattress spring machines have significantly improved in energy efficiency—using up to 50% less energy than older models, with advanced automation and intelligent power systems.

Understanding where these savings come from helps factory owners reduce costs, improve productivity, and align with global sustainability goals.

What Role Do Mattress Spring Machines Play in Production?

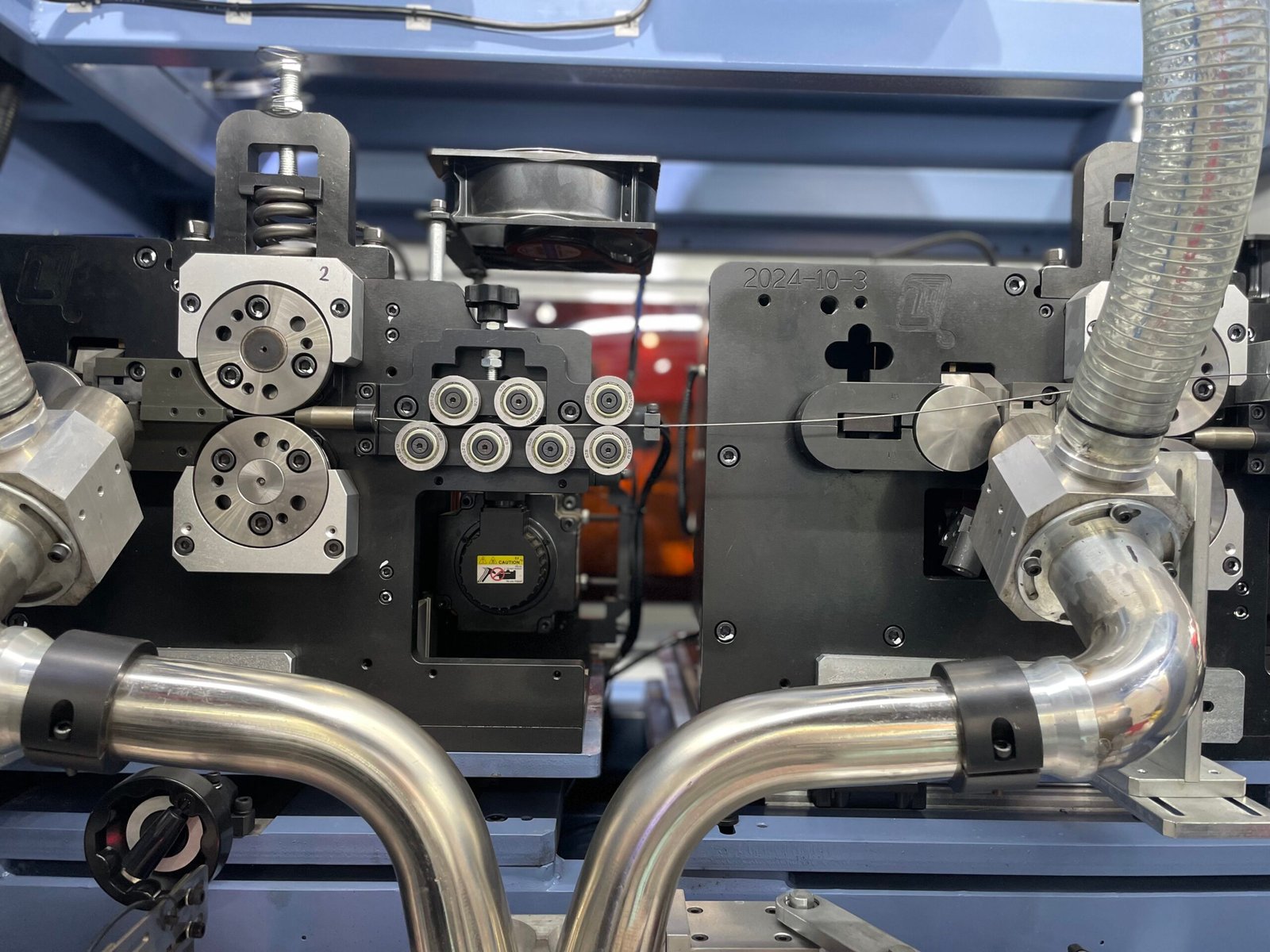

Mattress spring machines are the backbone of any innerspring or hybrid mattress factory. They form and assemble springs into stable cores that define mattress comfort and durability.

These machines produce:

- Bonnell springs (hourglass-shaped, connected)

- Pocket springs (individually wrapped, zoned support)

- Continuous coils (single wire rows)

Energy efficiency in these machines isn’t just a “nice-to-have”—it directly affects:

- Production cost

- Environmental footprint

- Compliance with green manufacturing policies

How Has Technology Improved Their Efficiency?

New-generation machines aren’t just faster—they’re smarter.

Key Technological Advancements:

| Feature | Benefit |

|---|---|

| Automation and robotics | Reduce human error, optimize movement |

| Energy-efficient motors | Lower power consumption without sacrificing torque |

| Smart sensors and IoT | Monitor performance and energy in real time |

| Predictive maintenance alerts | Prevent breakdowns that waste power and time |

| Precision controls | Minimize overuse of materials and power surges |

📌 Example: Our latest double-wire pocket spring machine uses 30% less energy per coil compared to a 2010 model—while producing 2x faster.

What Are the Actual Energy Consumption Metrics?

Energy consumption is typically measured in kilowatt-hours (kWh) per day or per unit produced.

Old vs. Modern Machine Comparison:

| Machine Type | Energy Use (Old) | Energy Use (New) | % Improvement |

|---|---|---|---|

| Bonnell spring machine | \~35 kWh/day | \~18 kWh/day | 48% |

| Pocket spring machine | \~40 kWh/day | \~22 kWh/day | 45% |

| Continuous coil machine | \~30 kWh/day | \~16 kWh/day | 47% |

These numbers vary by production hours and settings, but most modern machines cut energy usage by 35–50% on average.

How Efficient Are They with Raw Materials?

Energy efficiency isn’t only about electricity—it’s about reducing waste, too.

Material Efficiency Features:

- Precision wire cutters reduce offcuts

- Advanced gluing systems reduce over-application

- Coil form optimization minimizes scrap

With these systems, material waste drops by 20–30%, which also means less energy needed for handling and disposal.

How Does Operational Efficiency Support Energy Savings?

Modern machines maximize output per watt by minimizing downtime and improving speed.

Operational Efficiency Gains:

| Factor | Impact |

|---|---|

| Faster cycle times | Lower energy per unit |

| Reduced rework rate | Less wasted power and fewer remakes |

| Fewer unplanned stoppages | Less frequent high-energy startups |

We’ve seen customers improve unit-per-hour rates by 40–60% using upgraded machines with newer control software.

What Energy-Saving Features Do These Machines Include?

Manufacturers now build in smart energy systems.

Common Energy-Saving Features:

- Energy-efficient servo motors

- Standby mode after inactivity

- Power consumption analytics dashboards

- Regenerative braking (on motion axes)

- Load-based power optimization

These features contribute to 10–20% savings on top of basic mechanical upgrades.

How Do These Improvements Help the Environment?

Lower energy = lower emissions, especially in countries using fossil-fuel-based electricity grids.

Environmental Benefits:

- Lower CO₂ footprint per unit produced

- Reduced material transport energy due to less scrap

- Smaller facility cooling loads (thanks to low-heat motors)

If a factory replaces three old machines with new energy-efficient ones, they can cut over 25,000 kWh/year, equivalent to removing 20+ tons of CO₂ annually.

What Are the Cost Implications?

Initial machine upgrades cost more—but pay back quickly.

Cost Breakdown:

| Expense Area | Old Machine | New Machine |

|---|---|---|

| Monthly Energy Bill | \$450–\$600 | \$200–\$300 |

| Scrap Disposal | \$150/month | \$50/month |

| Unplanned Downtime Costs | Higher (frequent) | Lower (rare) |

| ROI Payback Time | – | 12–18 months |

With energy prices rising, payback windows are shortening. Some customers recover upgrade costs in under a year.

Any Real-World Case Studies?

Yes, and the results are compelling.

Case Study: Southeast Asia Mattress Plant

- Replaced 2 old pocket spring machines with newer, high-efficiency models

- Energy use dropped by 42%

- Production increased by 55%

- ROI achieved in 14 months

Case Study: Mid-size Factory in Europe

- Switched to continuous coil machines with regenerative drive systems

- Saved \$5,800/year in energy costs

- Qualified for carbon credit tax deductions

What’s Next for Energy Efficiency?

The next decade will bring even more innovation.

Trends to Watch:

| Innovation | Expected Impact |

|---|---|

| AI-driven coil algorithms | Optimize coil spacing and reduce torque loads |

| Renewable-powered machine lines | Direct solar integration for daytime operations |

| Cloud-based energy monitoring | Factory-wide consumption dashboards for decision-making |

| Lighter materials | Lower resistance and less power needed to form springs |

We’re also seeing rising demand for “Eco-Certified” production lines—machines that are verified as low-energy by independent bodies.

Conclusion

Modern mattress spring machines are built with energy efficiency in mind—from smart motors to regenerative drives and better material use. These upgrades not only reduce power bills, but also make your production greener and more competitive.

The best part? You don’t have to sacrifice speed or quality to save energy. In fact, with the right machine, you can have all three.